Project Background: As a global leader in automotive system components, denso has established 38 affiliated companies in China. The Wuxi factory, where the project is located, focuses on the production and sales of CI display screen audio systems, navigation systems, and AE engine control ECUs.

With rapid technological innovation and growing market demand, the Wuxi factory faced several challenges:

Scattered and Diverse Materials: The factory dealt with a wide range of materials with irregular packaging and a high rate of lost containers.

Limited Storage Space and High Material Flow Efficiency: The utilization of raw material storage space was low, and manual handling efficiency was poor.

High Management Complexity: Asset management was challenging, and the costs of material requisition, storage, dispatch, and inventory were high.

High Reliability Requirements: The automotive industry's strict environmental demands (transportation, storage, operation, etc.) required high reliability for automotive electronic materials.

Narrowing Profit Margins: Rising labor and raw material costs, along with continued pressure from customers to reduce prices, squeezed profit margins.

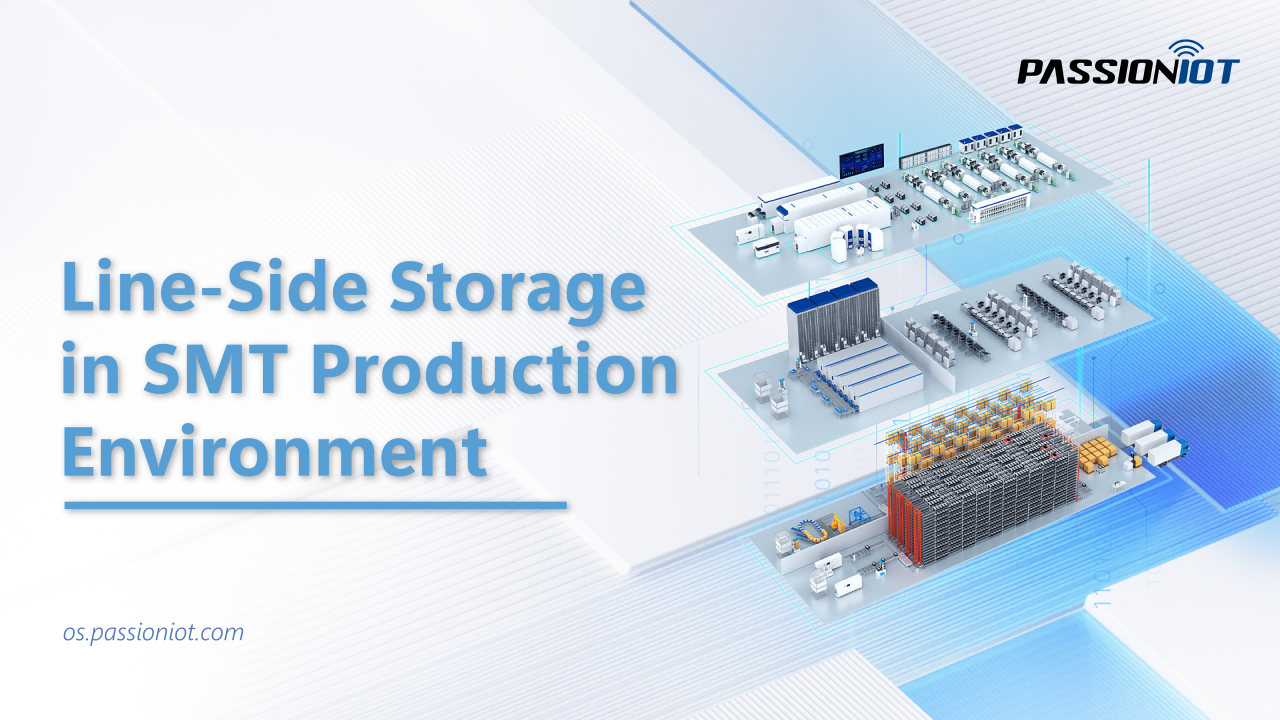

PassionIOT Solution: To address these issues, PassionIOT developed a customized flexible line-side storage and logistics solution for denso's Wuxi factory. The solution automated the entire process from warehousing to picking, material dispatch, transportation, and usage.

Material Registration—Precise and Fast Labeling:

PassionIOT's automated visual screening and labeling machine enabled precise and fast labeling of IQC-approved materials, categorized by type. The system's high efficiency, ease of use, and one-code-per-item intelligent recognition improved traceability.

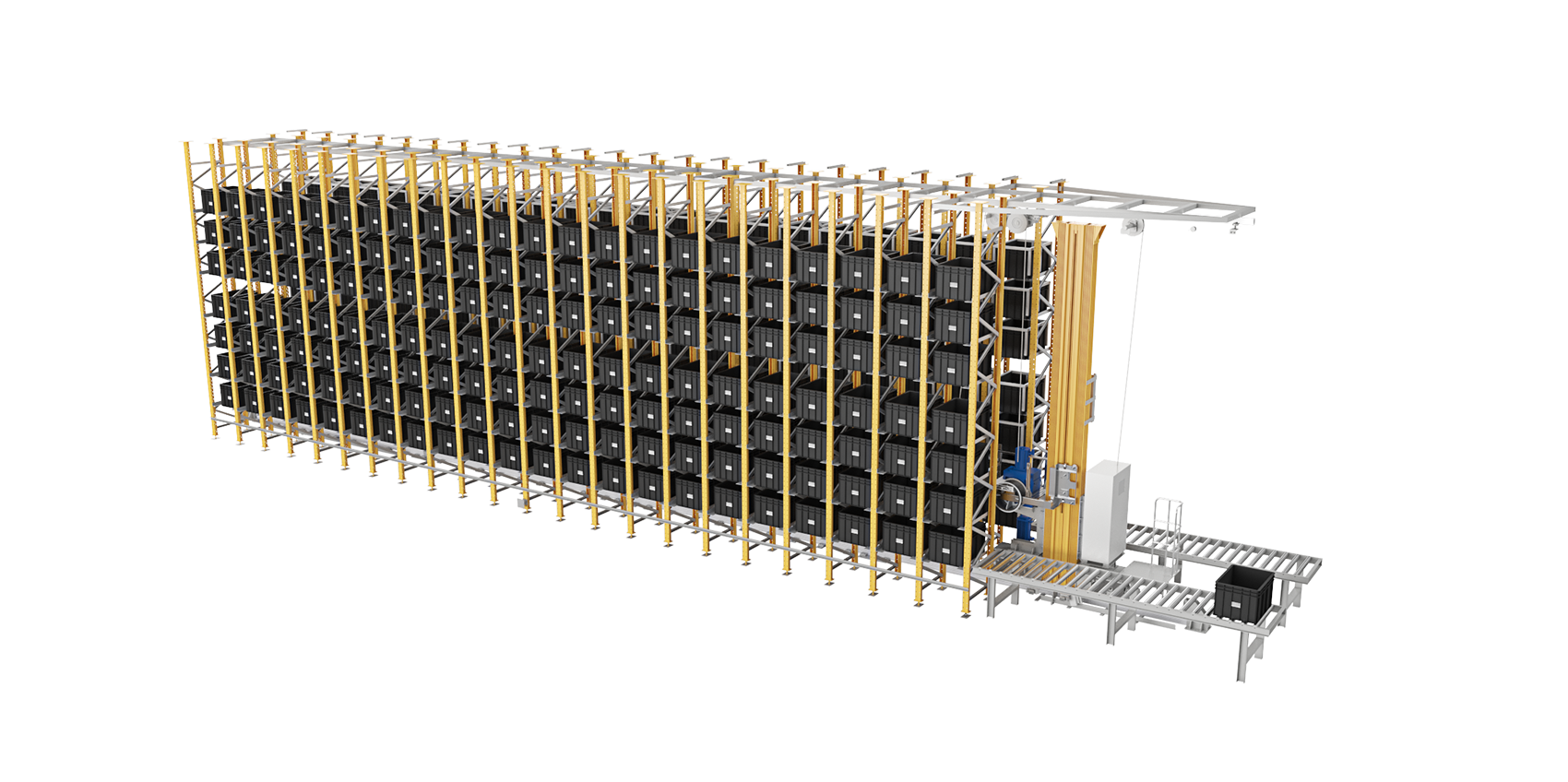

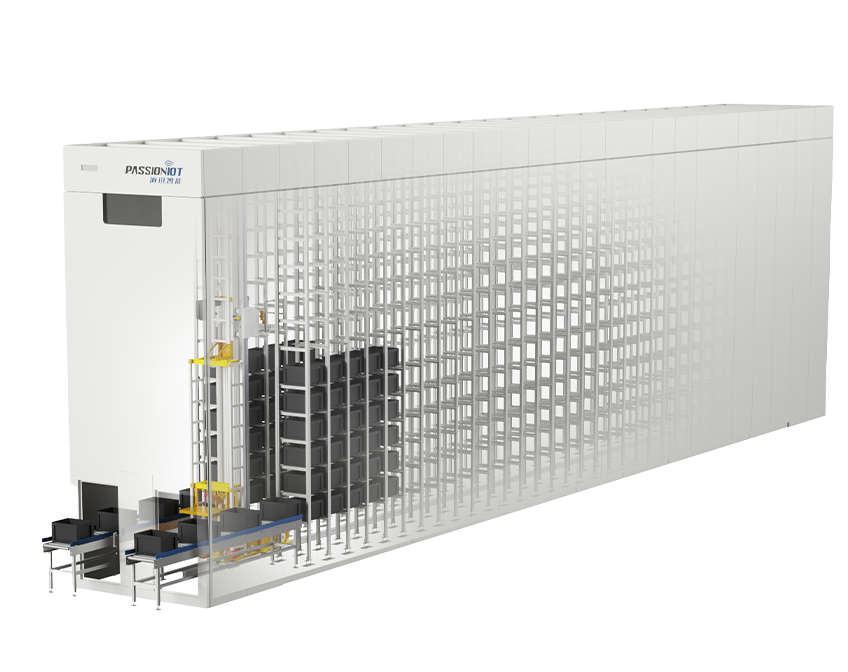

Warehousing and Picking—High-Density Flexible Storage:

To maximize storage space, PassionIOT designed a 15m long mixed dual-channel intelligent reel warehouse. With a compact and efficient multi-layer design, continuous left-right side batch material changes without stopping, and high-precision robotic sensing and retrieval, the warehouse handled over ten thousand materials daily. It was compatible with storage for 7 to 15-inch materials, increasing storage capacity by approximately 70%.

AGV Bin Storage—Automated Handling and Storage:

Under the direction of the iWMS system, custom 2.98m AGV bin robots performed efficient picking and timely delivery to target storage locations. Each robot achieved a picking efficiency of over 38 bins per hour, with an accuracy rate of 99.99%.

iWMS Intelligent Management Platform—The Brain and Nerve Center of the Storage System:

In the workshop, customized BI dashboards displayed real-time information on storage utilization, work order material preparation, personnel workload statistics, and temperature/humidity conditions.

Project Results:

80% Increase in Storage Space

30% Improvement in Operational Efficiency

50% Increase in Picking Efficiency

60% Reduction in Labor Input