Project Background:

As a leading company in the commercial vehicle market, FAW Group's Hongqi Prosperity Plant integrates advanced global technologies with a standard annual production capacity of 240,000 vehicles. The high level of automation on the production line also increases the complexity of warehouse picking

Low Space Utilization:

As production at the Hongqi Prosperity Plant increases, coupled with the challenges of sale channel transformation, high picking demands lead to low surface utilization in the warehouse, resulting in insufficient storage space.

High Picking Difficulty:

The automotive industry is characterized by "small batches, multiple varieties, and made-to-order production." The wide variety of materials, differing specifications, and complex operating environments in the workshop make traditional manual storage operations prone to errors and lower safety.

Poor Inventory Management:

Materials are often stacked in a disorganized manner, making it difficult to accurately monitor the warehouse situation. When issues arise with orders, it is challenging to trace the source, and manual data analysis becomes overwhelming.

PassionIOT Solution:

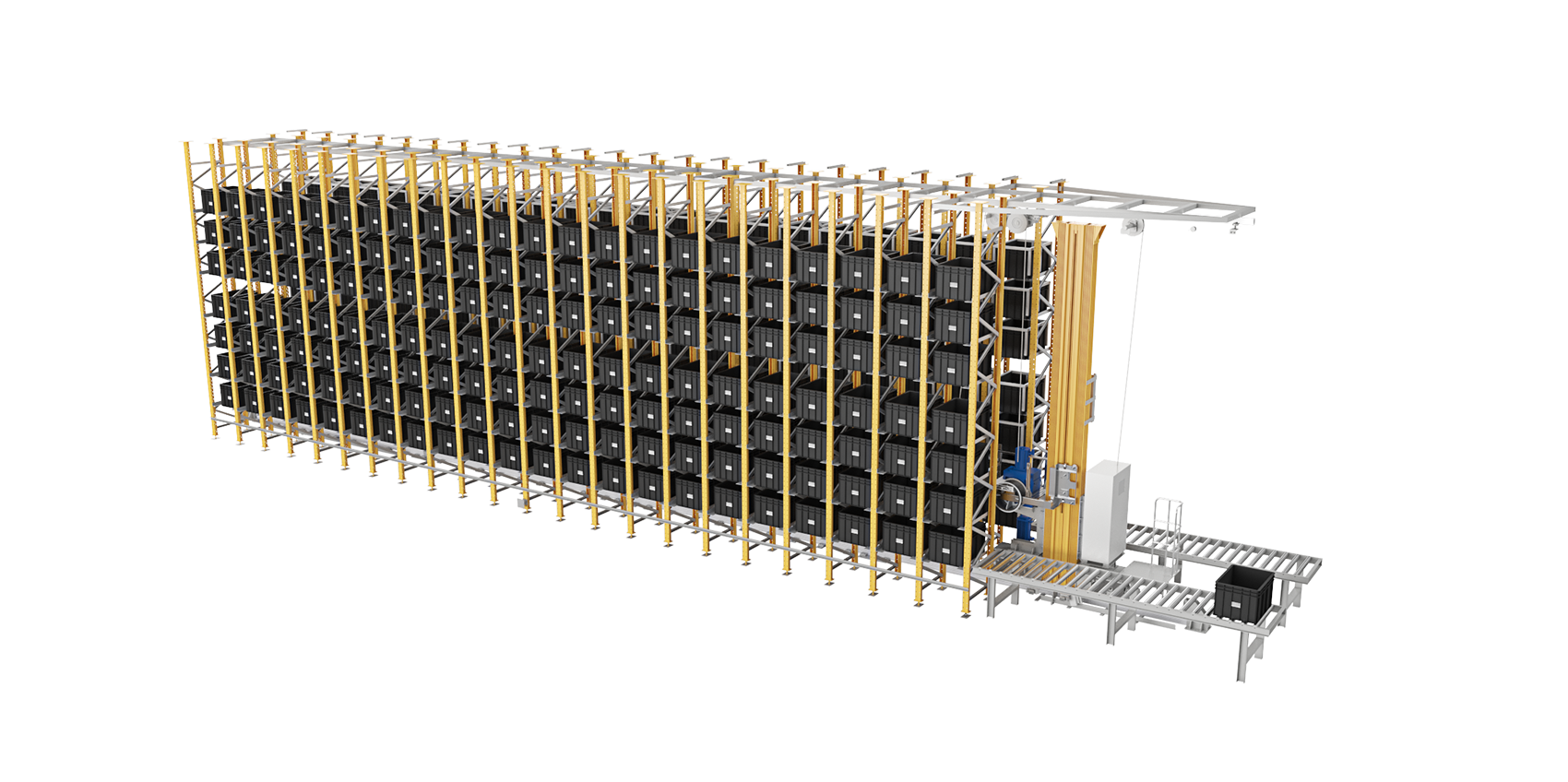

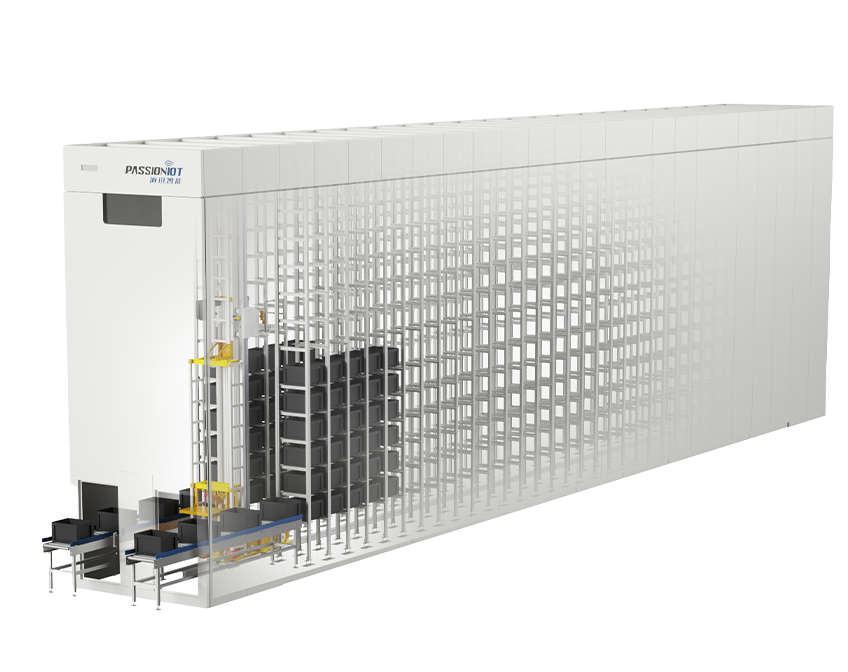

To address the client's needs, PassionIOT implemented the latest vertical lift storage system solution to achieve intelligent warehouse management.

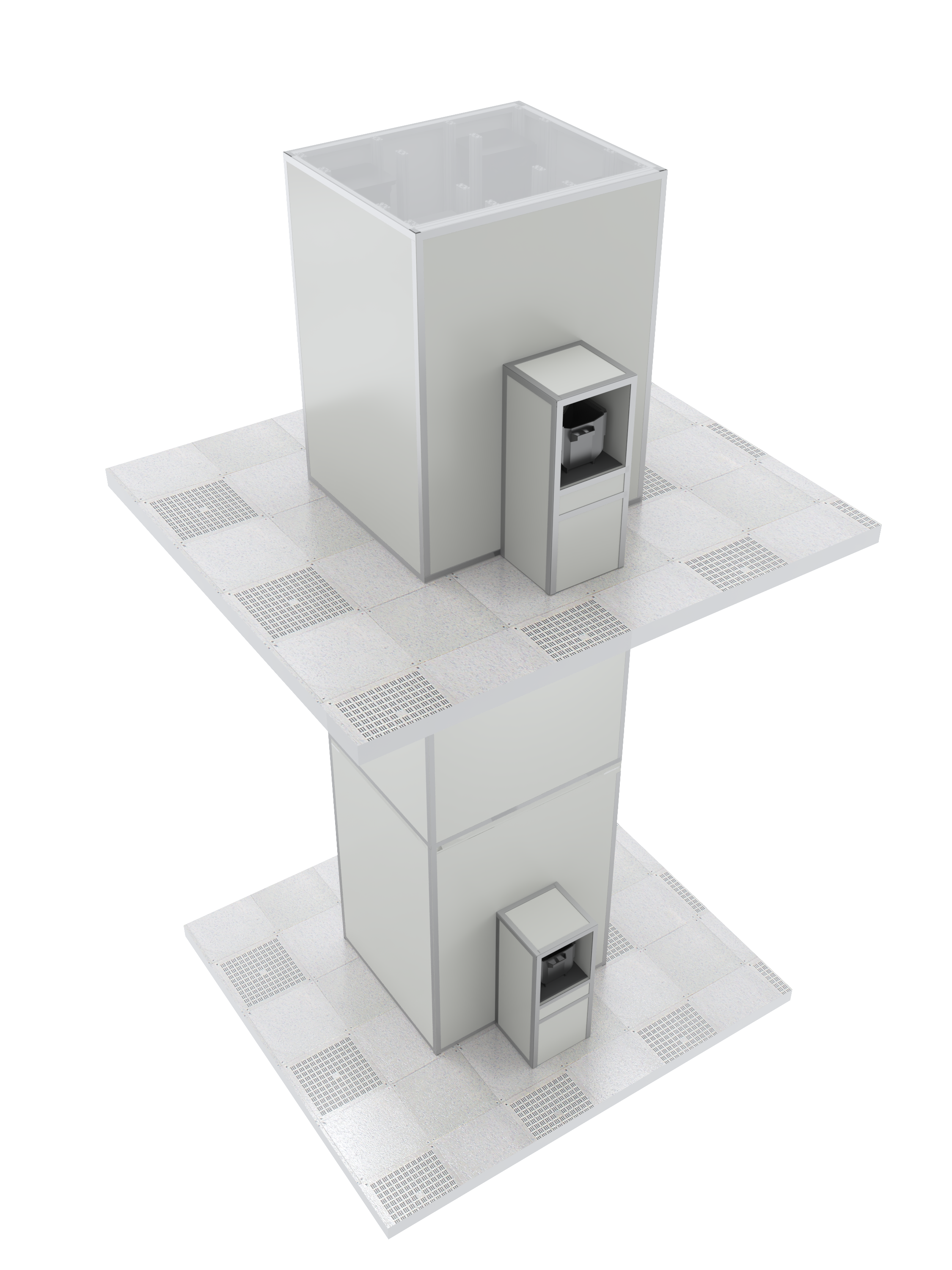

The vertical lift storage system deployed in this project stands approximately 9.1 meters tall. By fully utilizing the line-side space, it meets the tight storage requirements for various materials, including standard parts, critical components, and new model parts, within the welding workshop.

The system’s lift automatically delivers bins with target parts to the exit port, enabling a complete "goods-to-person" process. Workers can easily complete picking operations without moving, doubling picking efficiency. Complex and cumbersome order picking becomes quick and straightforward, even for newcomers, while ensuring the safety of both people and goods.

The optimal storage density and flexible storage strategy enabled the automation of parts retrieval and high-frequency storage picking within the workshop, freeing up as much as 80% of floor space.

With PassionIOT's warehouse management software, material and work order information is synchronized in real-time, allowing staff to instantly query and manage the latest work orders and inventory data.

Project Results:

Implemented a "goods-to-person" warehouse circulation strategy.

Optimized 80% of floor space, enhancing automated inventory control.

Achieved 49.9% picking accuracy with an 8% increase in picking efficiency.

Improved production efficiency and production line information management.