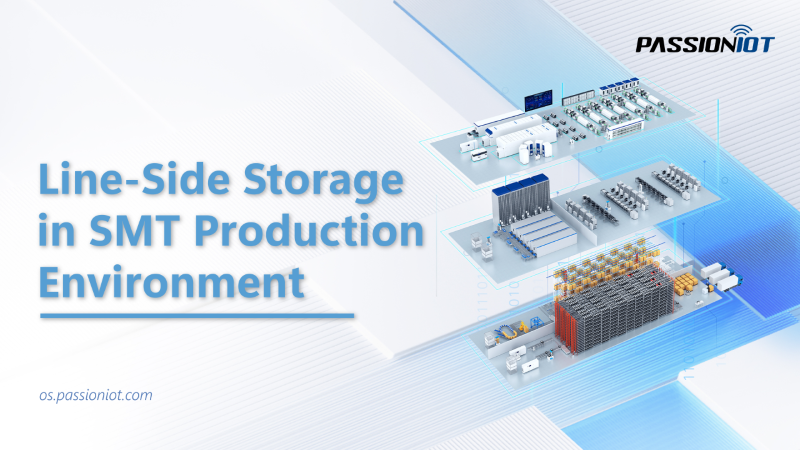

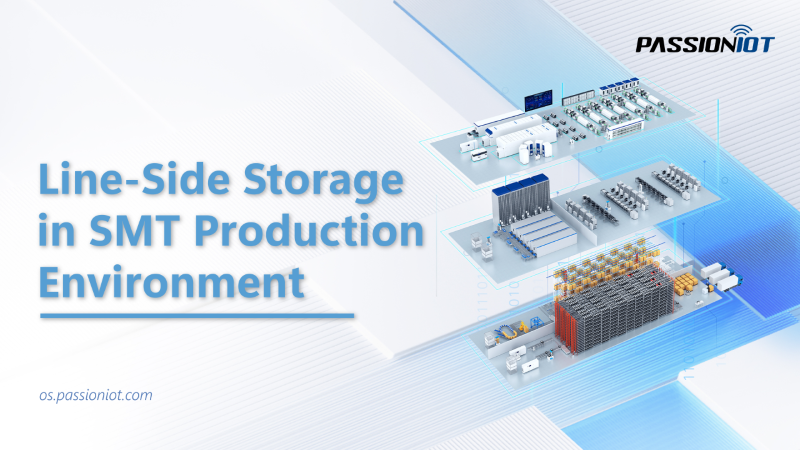

In modern manufacturing, especially in sectors such as electronics and automotive, the concept of line-side storage has become integral to efficient production. Line-side storage places essential components and materials directly adjacent to the production line, reducing unnecessary movement and streamlining workers' access. This storage approach aligns well with lean manufacturing principles, which emphasize minimizing waste and maximizing productivity.

What is Line-Side Storage?

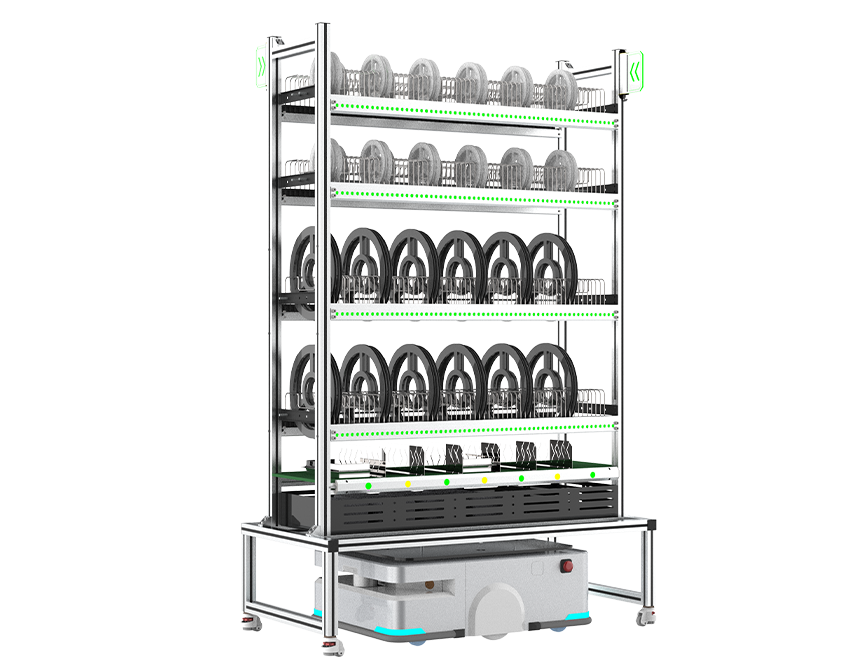

Line-side storage involves strategically positioning parts and materials close to the production line, minimizing travel time for workers who require immediate access to these materials. Rather than retrieving components from a central location, line-side storage enables teams to keep essential parts close by, ensuring a smooth, uninterrupted workflow. This strategy enhances Just-In-Time (JIT) practices, where materials arrive just as they are needed, thereby reducing inventory costs and freeing up valuable floor space for productive activities.

Advantages of Line-Side Storage in SMT Production

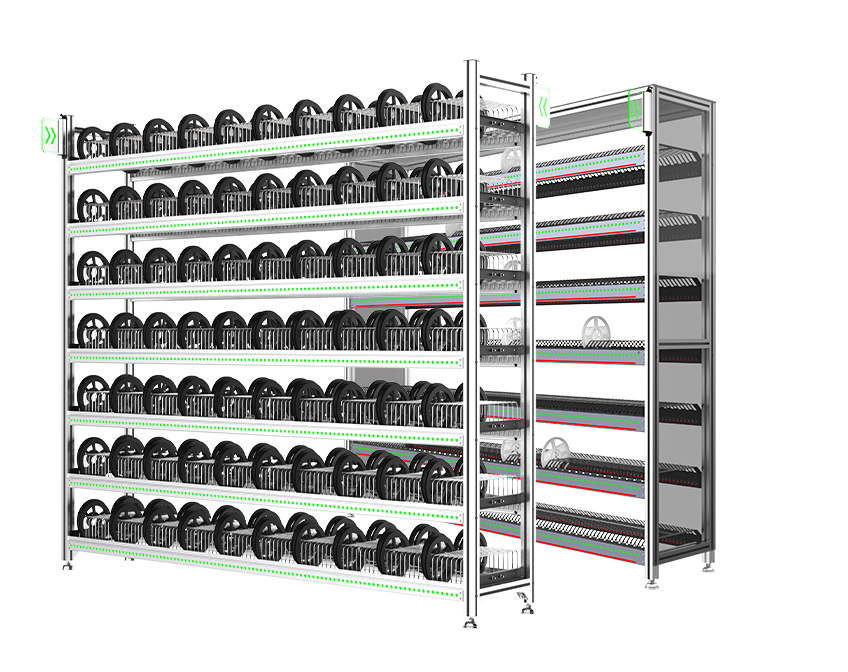

In Surface Mount Technology (SMT) production environments, line-side storage offers multiple benefits. SMT lines operate at high speeds and require precise, timely delivery of components to avoid bottlenecks and ensure continuous production. Here are some key benefits:

1. Reduced Handling Time and Improved Efficiency By placing components directly beside the production line, line-side storage cuts down on the time spent retrieving materials. This streamlined process is particularly valuable in SMT production, where even minor delays can disrupt operations. With line-side storage, the time needed to replenish parts is minimized, helping maintain high productivity levels.

2. Enhanced Quality Control Having components nearby allows quality checks to be conducted swiftly and more frequently. This rapid feedback loop ensures that defects are caught early, reducing waste and minimizing the risk of costly rework or scrapping.

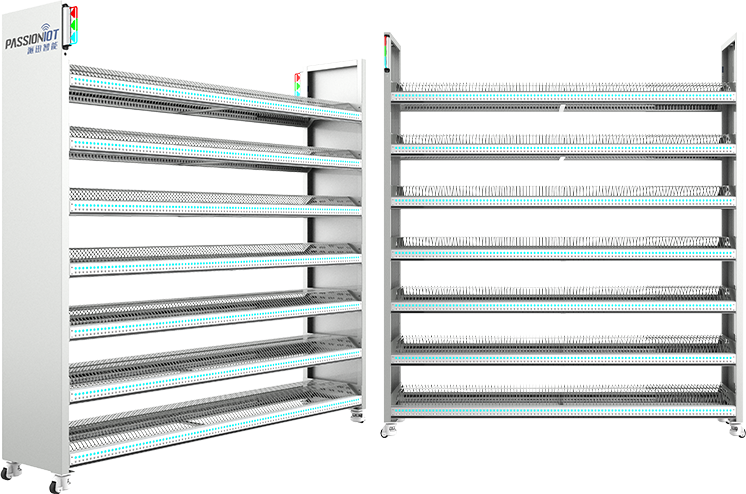

3. Optimized Space Utilization Line-side storage allows manufacturers to use space more effectively. Materials that are frequently used are kept close to the line, while items with lower demand can be stored in more remote areas. This flexible use of space helps in managing inventory levels efficiently and enhances the overall organization of the factory floor.

4. Increased Flexibility and Responsiveness Line-side storage provides greater flexibility to adapt to production changes, whether from design updates or urgent order requirements. By storing essential materials close to the line, teams can more easily respond to varying customer demands or shifts in production schedules, allowing the SMT line to handle customized or batch productions more fluidly.

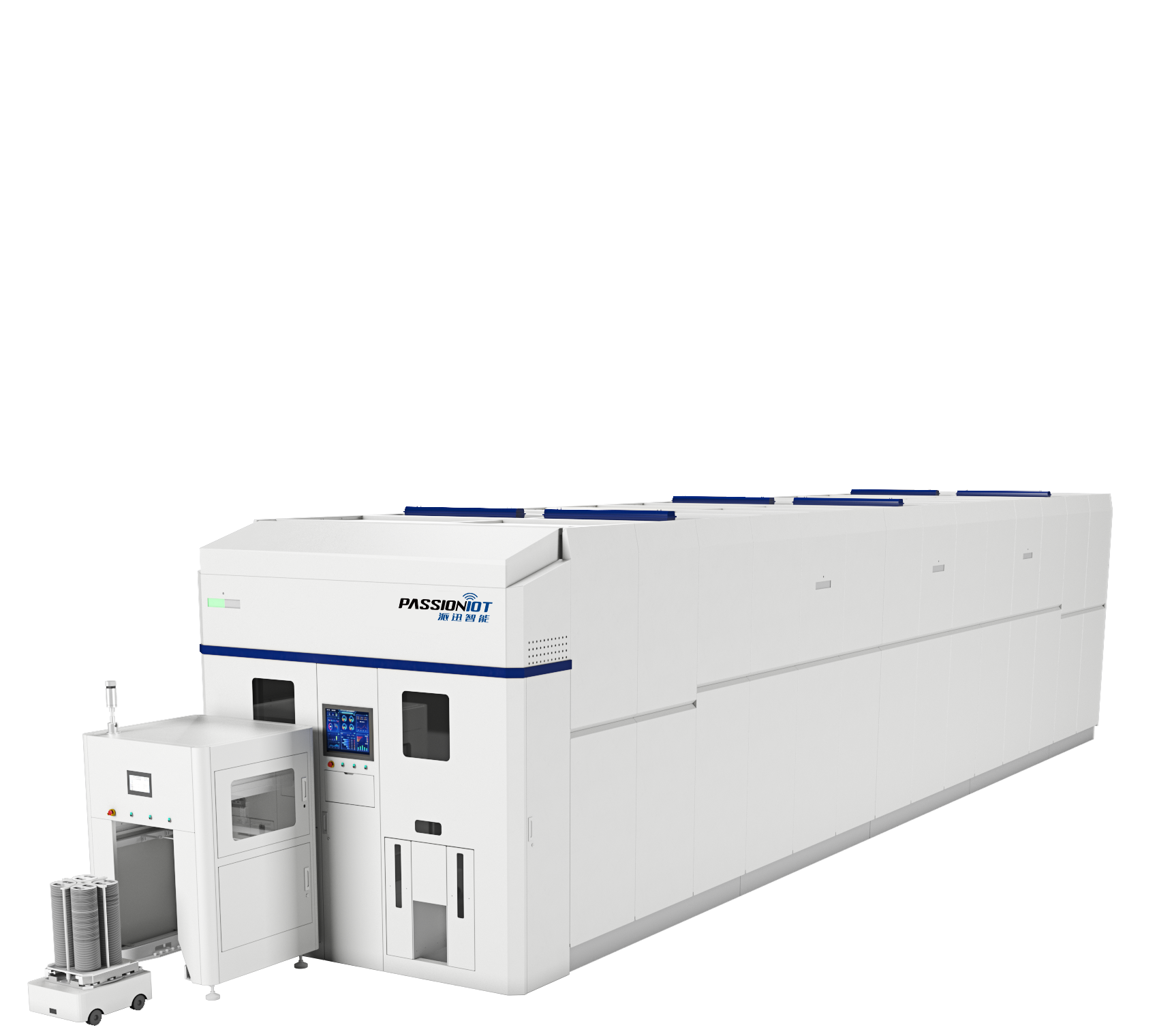

The Role of PassionIOT in Line-Side Storage Solutions

PassionIOT has long been dedicated to developing and refining line-side storage solutions tailored to the unique needs of SMT production. With robust expertise and continuous investment in this area, PassionIOT provides high-efficiency storage solutions that align with lean principles and support the evolving needs of clients across the industry.