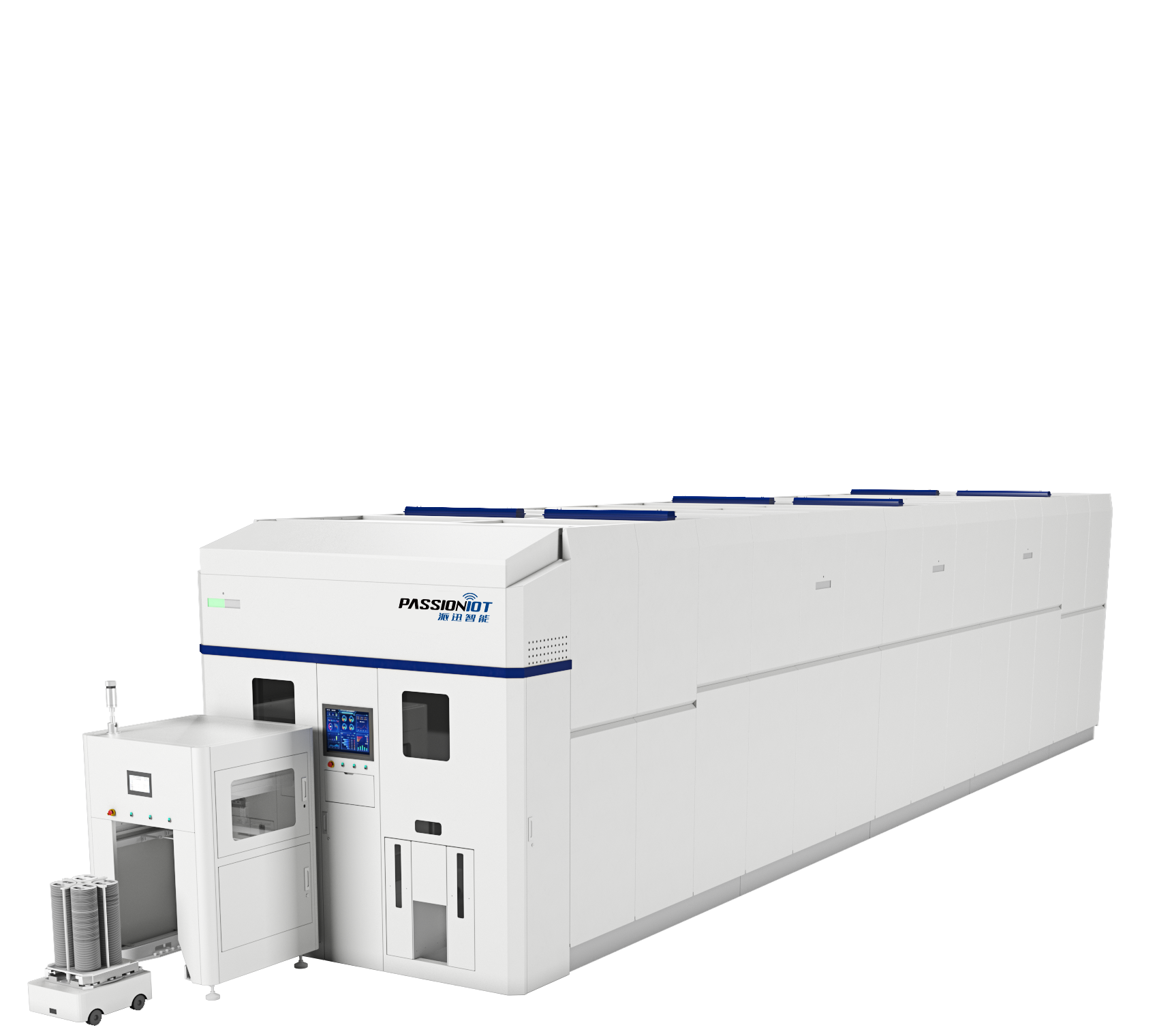

Efficient management of SMD (Surface Mount Device) materials is essential for modern electronics manufacturing. Intelligent storage systems, such as SMD smart warehouses, have transformed material handling by enhancing efficiency, accuracy, and operational control. Here’s a guide to effectively utilizing these systems for managing SMD materials.

1. Streamline Material Storage with Automated Systems

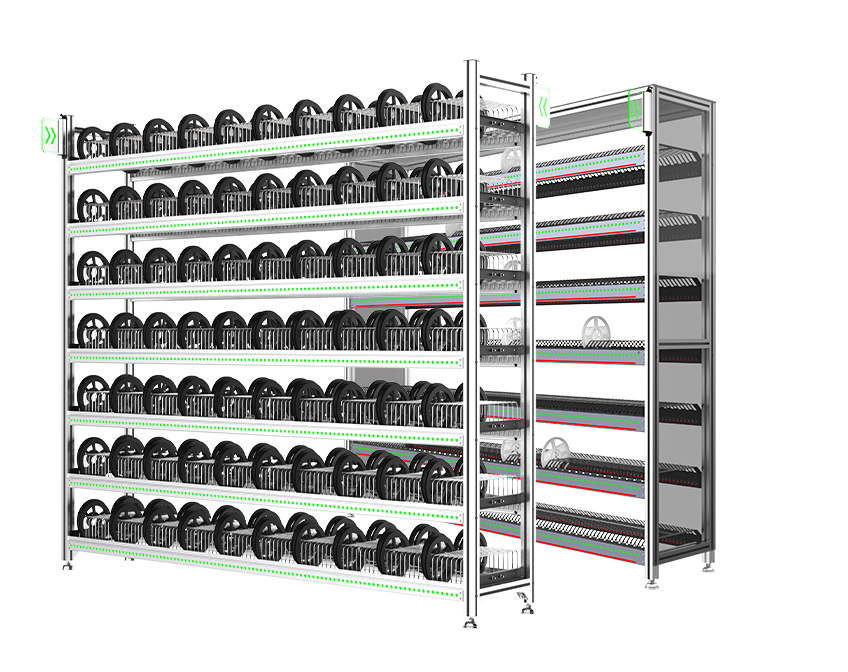

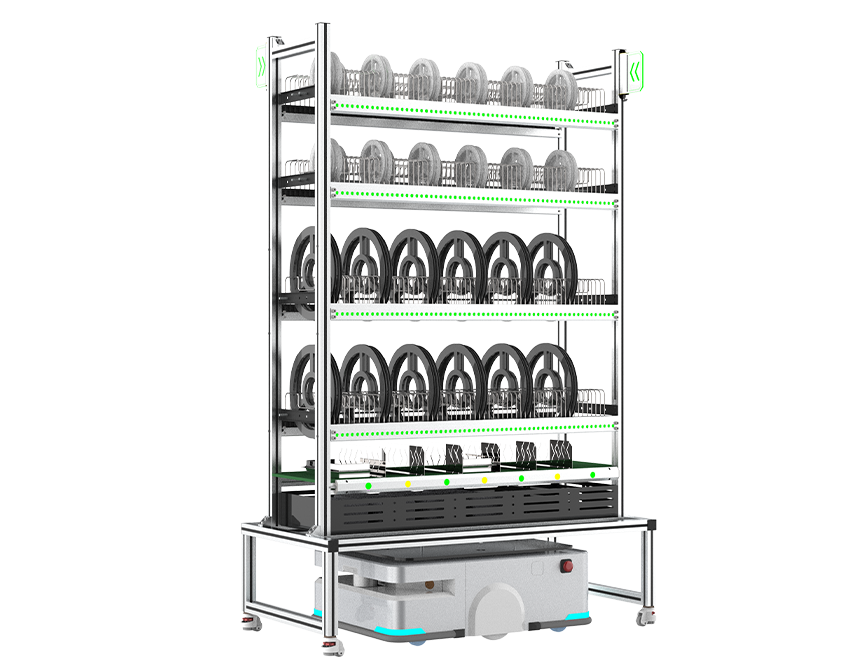

Intelligent storage systems are designed to store thousands of SMD reels in a compact, organized, and controlled environment. With automated loading and unloading features, these systems:

Reduce manual handling, minimizing errors and labor costs.

Provide controlled environments with temperature and humidity regulation to preserve material quality.

Maximize space utilization through modular and scalable designs.

By integrating automated storage, manufacturers can significantly streamline their operations and maintain a high standard of material organization.

2. Simplify Material Retrieval with Advanced Scanning Technology

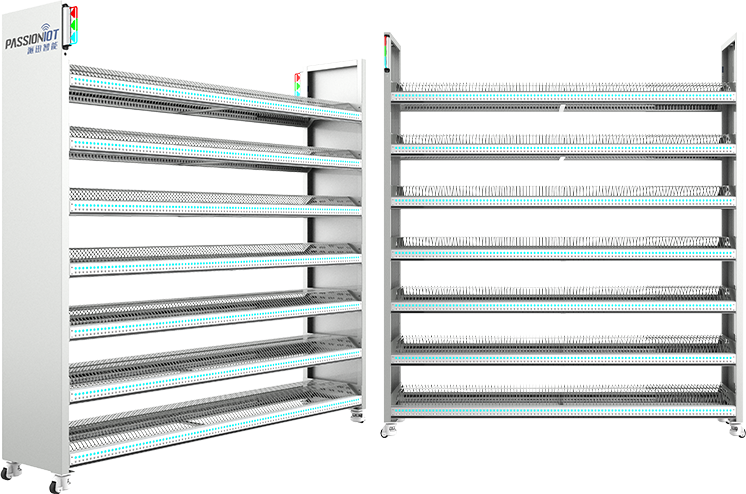

Efficient material retrieval is critical to meeting production schedules. Intelligent systems achieve this by:

Utilizing PDA or IPC-based interfaces for scanning reel barcodes and confirming rack locations.

Highlighting the target reel location with LED signals, ensuring quick and accurate retrieval.

Uploading real-time data to the central system, reducing search times and ensuring seamless production workflows.

This level of automation eliminates bottlenecks and accelerates production readiness.

3. Leverage Real-Time Data for Inventory Management

Modern intelligent storage systems are equipped with IoT and sensor technologies that provide real-time data on inventory levels and usage patterns. These features enable:

Accurate tracking of material usage and stock replenishment needs.

Integration with ERP or MES systems for synchronized supply chain management.

Advanced analytics to identify trends and improve operational decision-making.

Real-time insights empower manufacturers to maintain optimal inventory levels and reduce material shortages.

4. Reduce Waste Through Efficient Handling

Smart storage systems address common inefficiencies in traditional methods, such as:

Eliminating waiting times associated with manual handling and pallet-based systems.

Minimizing unnecessary movement and handling of reels, improving ergonomics.

Ensuring material integrity by maintaining ideal storage conditions.

These measures reduce waste, improve workflow efficiency, and contribute to sustainable manufacturing practices.

Adopting an intelligent storage system for SMD materials is no longer a luxury but a necessity for manufacturers aiming to stay competitive. By automating storage, retrieval, and inventory processes, these systems enhance operational efficiency, reduce errors, and support high-volume production demands. PassionIOT’s intelligent storage solutions exemplify how technology can revolutionize material management, enabling manufacturers to meet the challenges of modern electronics production with confidence.