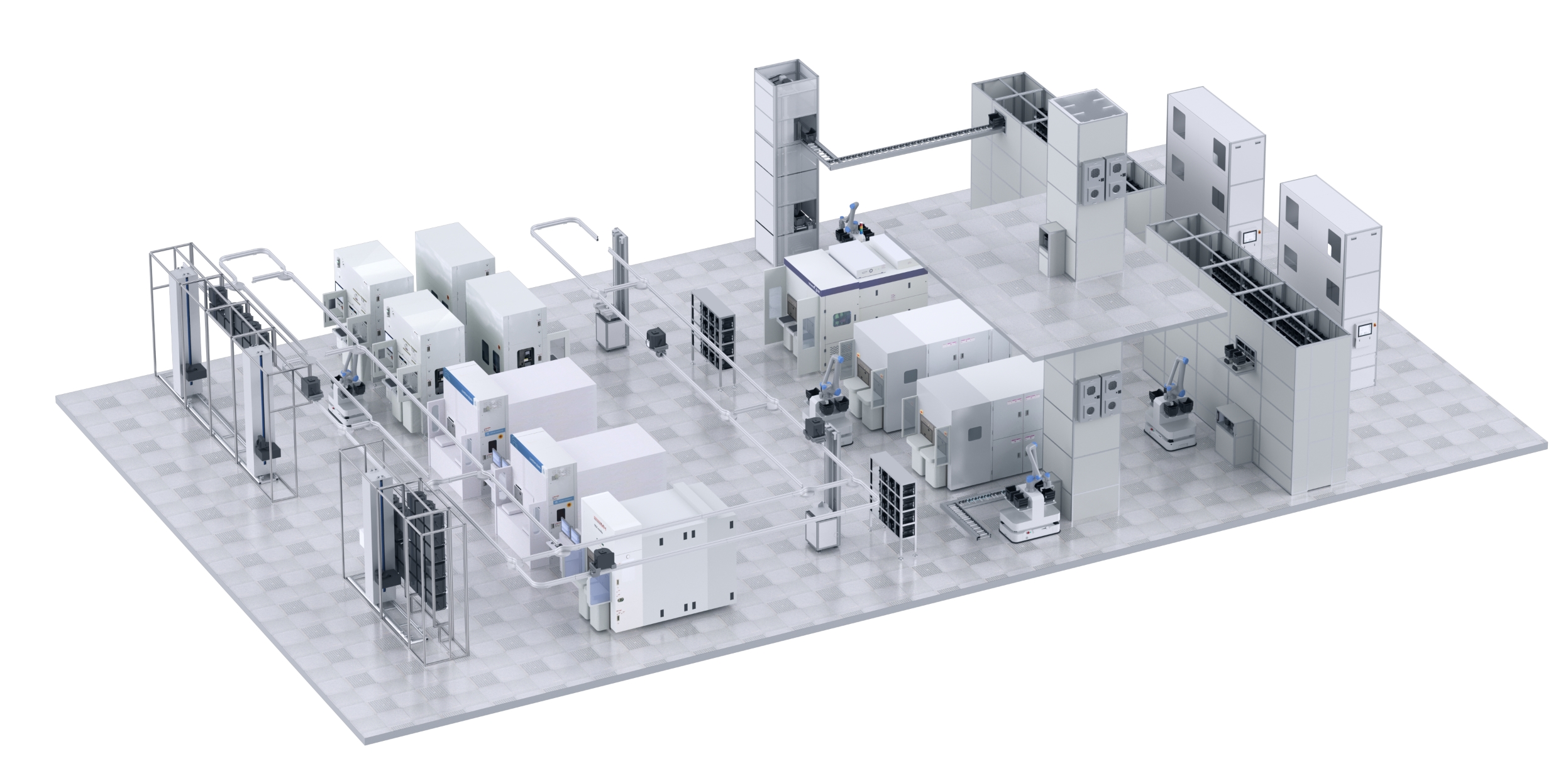

A leader in digital vision solutions, building transparent and efficient digital factories.

- Home

- ABOUT PassionIOT

-

PRODUCTS

- Electronic Manufacturing

- SMD Smart Wareh...

- SMD Smart Tower

- Solder Paste St...

- Smart Auto Labe...

- Inline X-Ray Re...

- Lineside X-ray ...

- Magazine Smart ...

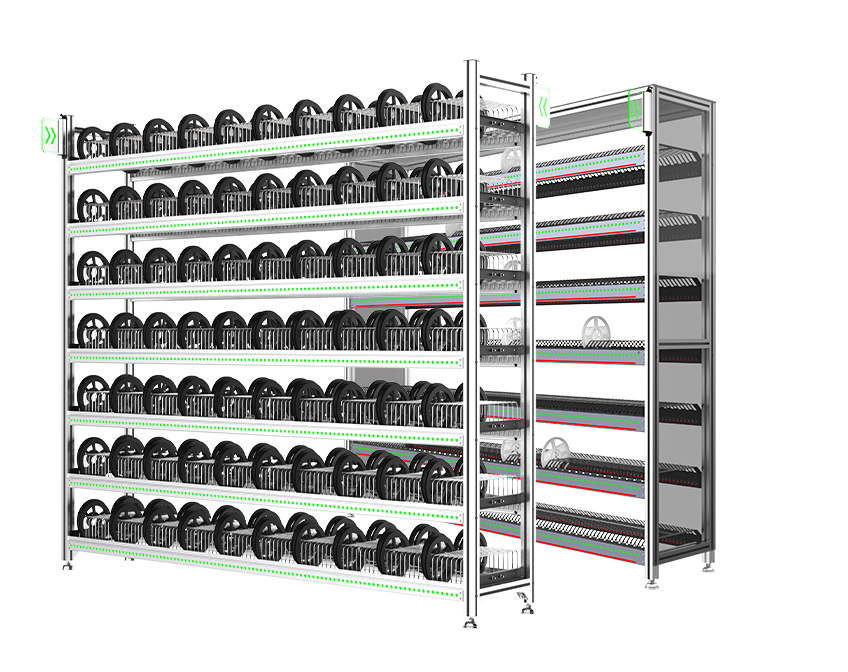

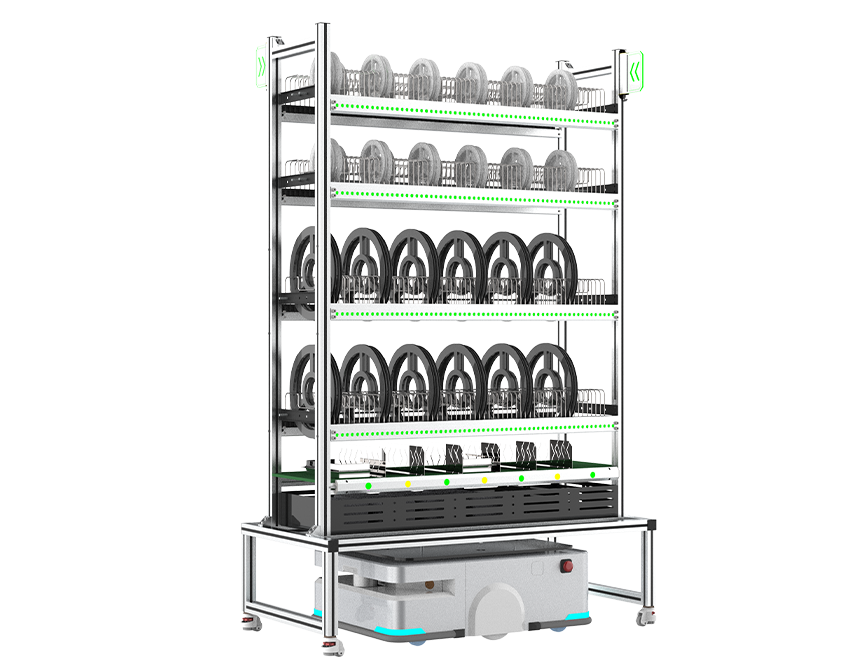

- SMD Smart Reel ...

- Pick by Light R...

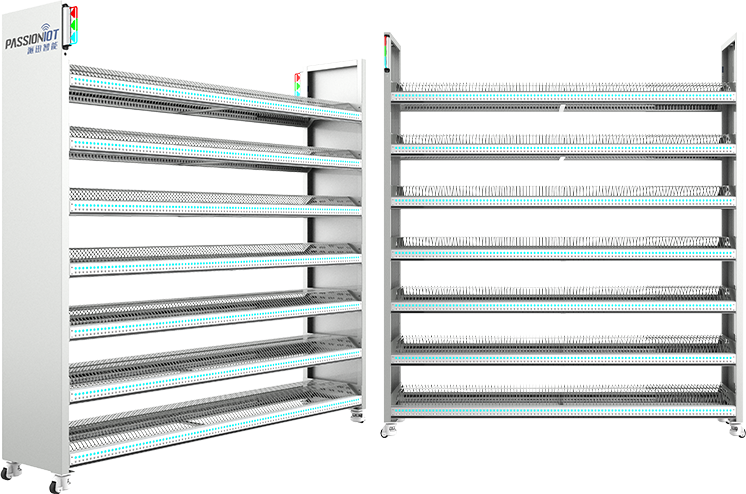

- AIoT Movable St...

- Stencil Storage

- Stacking Labell...

- Warehouse Integration

- Smart Vertical ...

- Smart Vertical ...

- Miniload

- AGV

- PassionIOT Soft...

- AS/RS Automated...

- SOLUTIONS

- CASE STUDIES

- EVENTS & NEWS

- CONTACT US

- DOWNLOADS

-

-

Bus: sales@passioniot.com

-

Web: www.passioniot.com

-

Add:Building B, No. 28, Heshun Road, Suzhou Industrial Park