Project Background:

SCC Shennan Circuit is a leading domestic supplier in the packaging substrate industry with strong technical capabilities. Their primary businesses include printed circuit boards, electronic assembly, and packaging substrates. Notably, their MEMS packaging substrates for silicon microphones hold over 30% of the global market share.

In 2019, as their business expanded and material types increased, the complexity of managing these materials grew. SCC Shennan Circuit used PassionIOT’s automated storage solutions to the automated and intelligent handling of raw materials and finished products. The project has been running steadily for nearly five years, achieving full manufacturing visibility and traceability, with a 70% increase in storage capacity, a 25% improvement in efficiency, and a 10% boost in production capacity.

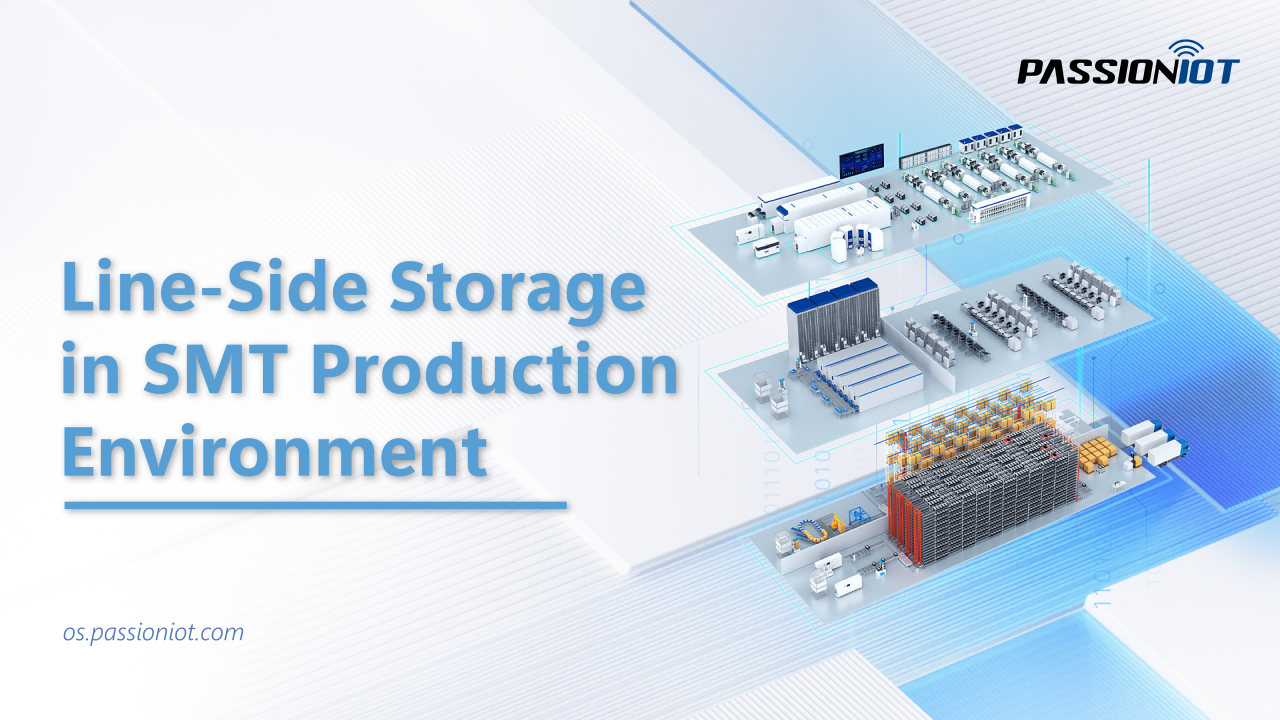

Building on the success of the Phase I project, SCC Shennan Circuit decided to collaborate with PassionIOT again to create a smart storage digital factory. By implementing PassionIOT’s flexible line-side storage solutions, the client aims to overcome business growth bottlenecks and further improve production and operational management through extensive digital management technologies.

PassionIOT Solution :

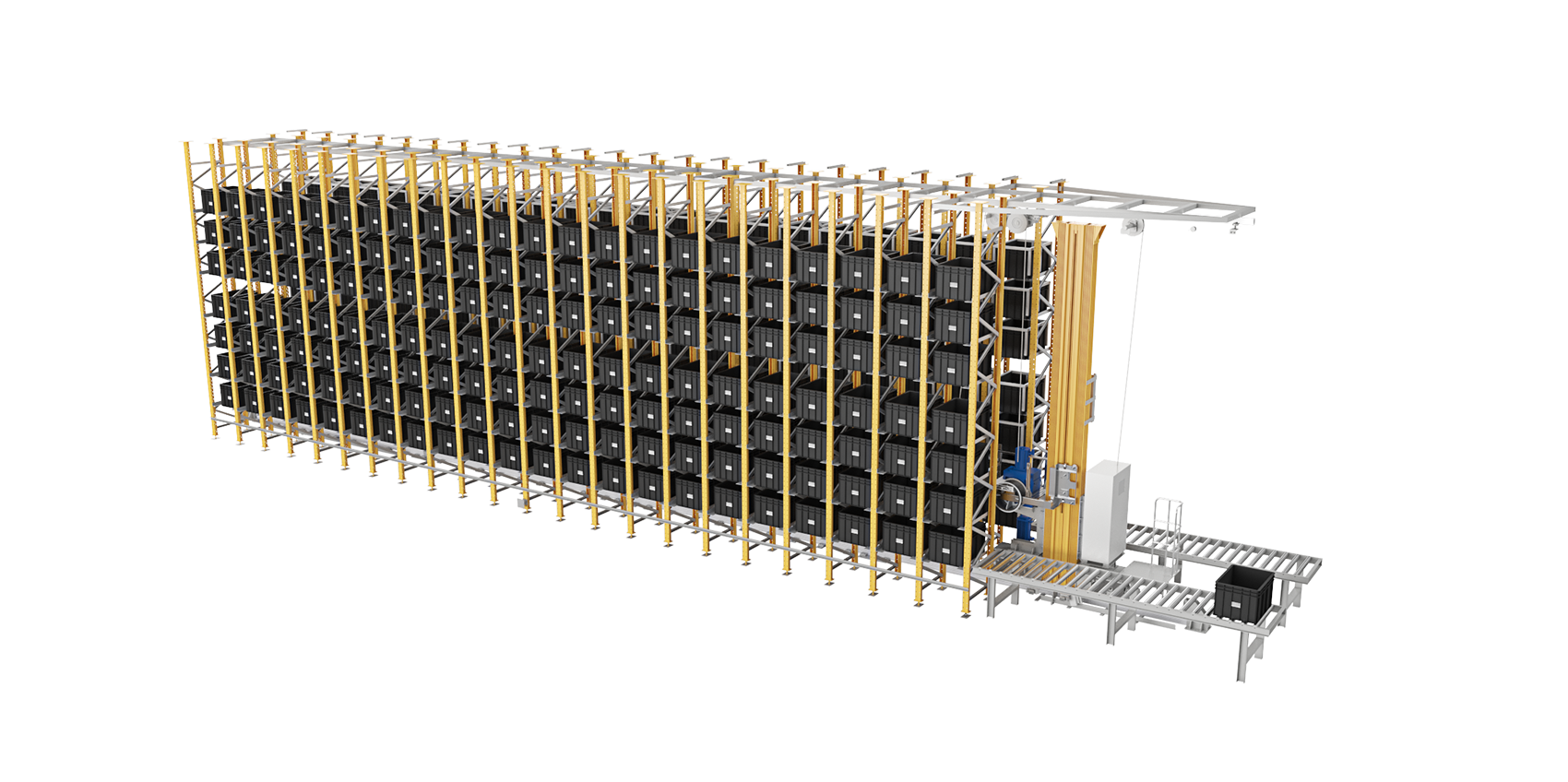

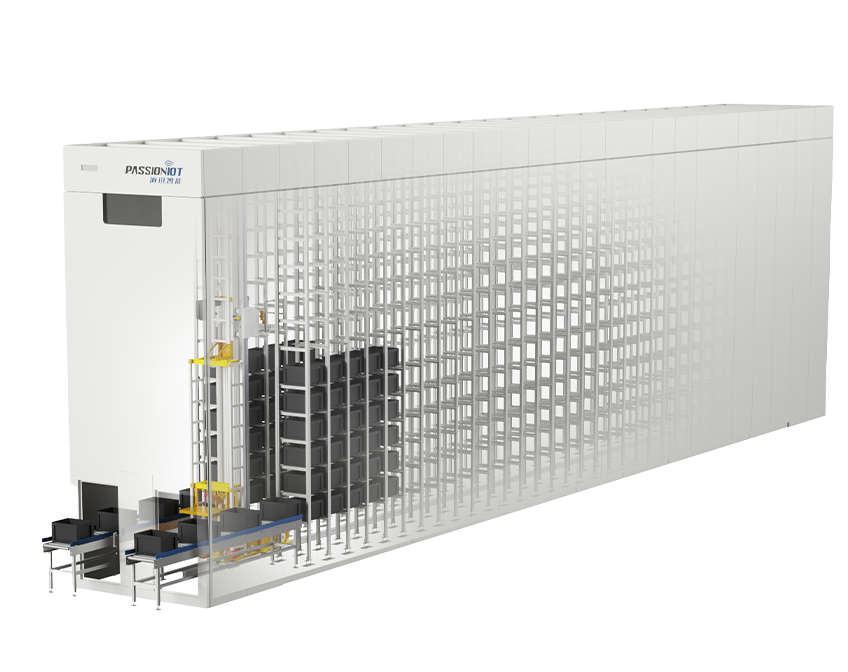

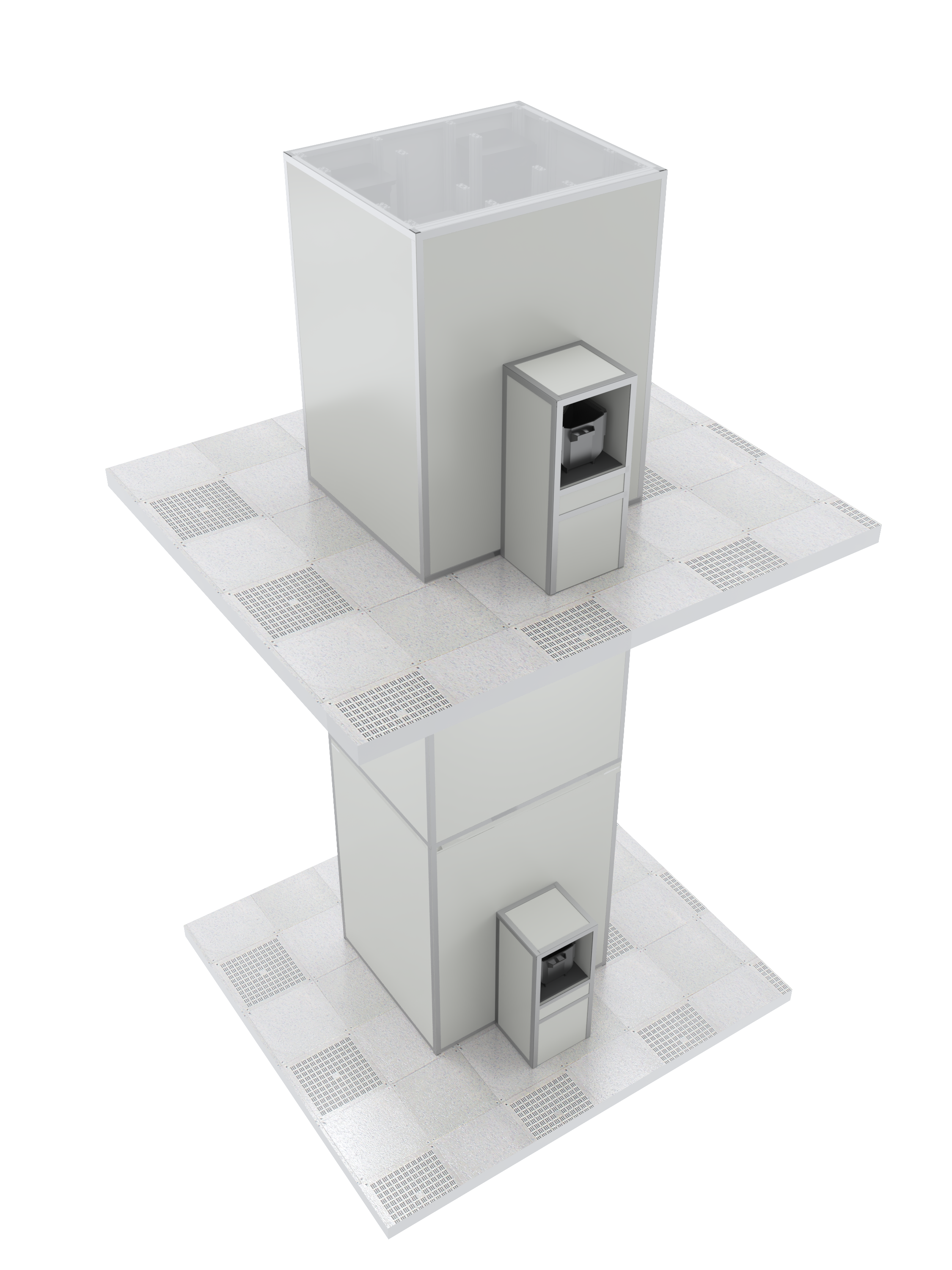

In the Phase II project, PassionIOT provided a highly flexible line-side material storage solution, including custom large-capacity intelligent storage equipment, automated labeling stations, automated material conveyor lines, automated bin interfacing with AGVs, and a specially developed iWMS warehouse management system.

(1)Intelligent Management Platform: Unified deployment with automated storage and retrieval, precise inventory counting, and FIFO (First-In, First-Out) principles, replacing manual picking and locating.

(2)High-Density Storage: Custom three-way double-deep storage, with over 50,000 electronic reels accommodated by a single storage unit, saving more than 80% of space.

(3)Fully Automated Precision Material Dispatch: Significantly improves picking efficiency and accuracy, promptly responding to production line demands.

(4)Integration of Material and Data Flows: Optimizes multiple targets, including lean inventory, labor efficiency, and reduced changeover times.

The client’s repeat purchase is a testament to PassionIOT’s expertise in designing line-side storage solutions. It also signifies that the company’s hardware and software products and technologies have passed rigorous assessments from industry leaders and have been proven effective in complex application scenarios.