At PassionIOT, we continuously strive to improve the efficiency and accuracy of smart manufacturing processes. As a company specializing in intelligent storage and manufacturing solutions, we understand the importance of precision and reliability in electronic production lines. Two key areas where we focus our efforts are X-ray component counting and solder paste storage, both critical to maintaining smooth and error-free assembly operations in today’s competitive environment.

Precision in Inventory Management through X-Ray Technology

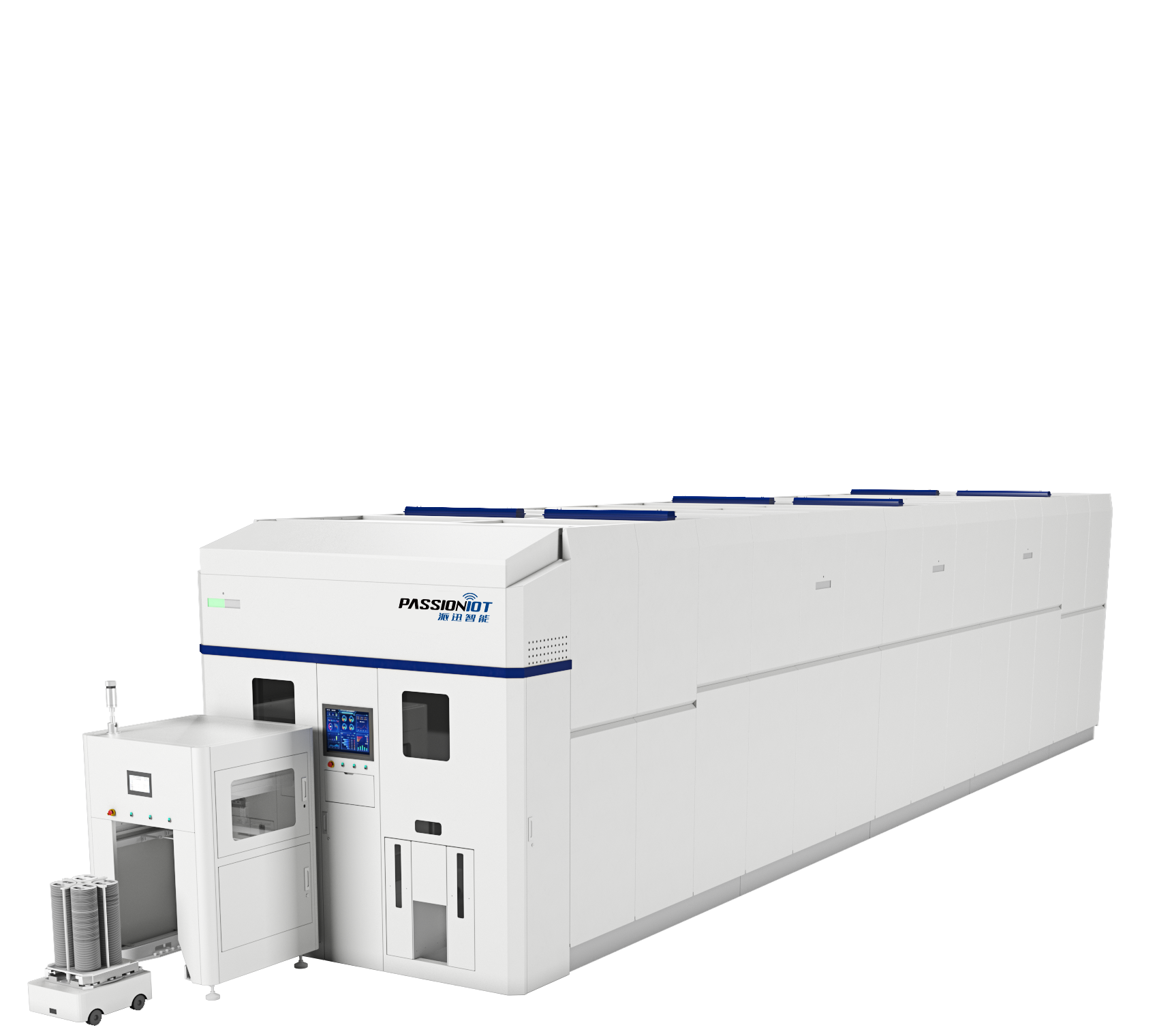

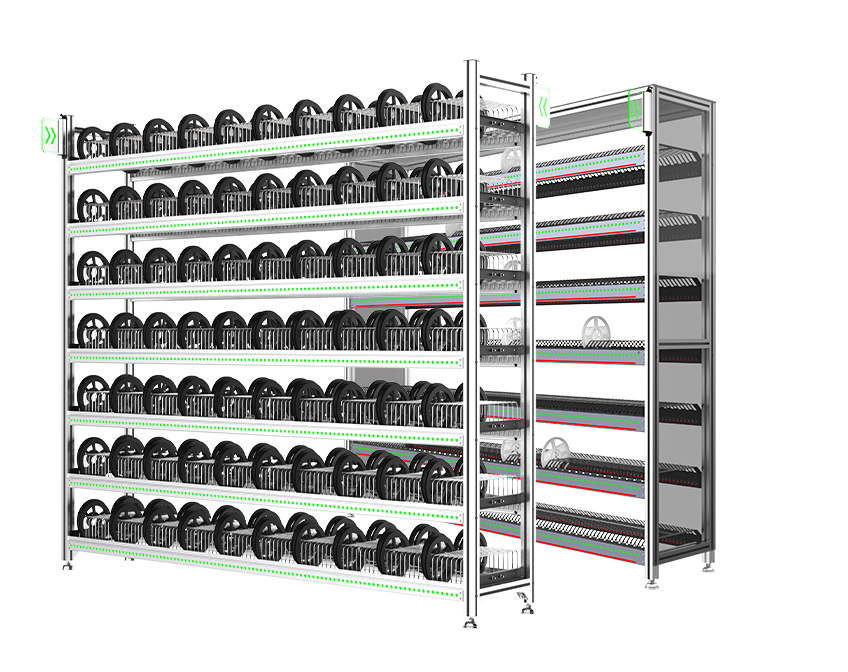

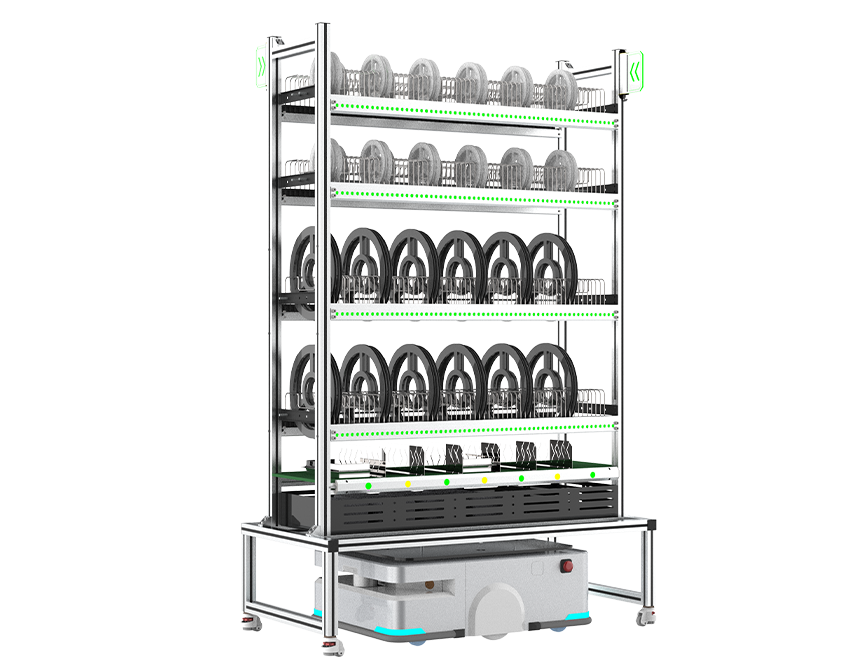

One of the essential technologies we implement is X-ray component counting, which allows for highly accurate inventory tracking of components on reels and trays. Unlike traditional counting methods, our X-ray component counting system uses advanced imaging technology to detect the exact number of electronic parts without manual intervention. This innovation helps to minimize human error and ensures that production lines never halt due to missing or miscounted parts. The application of X-ray component counting technology in our solutions supports our clients in maintaining seamless workflows, reducing waste, and optimizing inventory levels across various manufacturing environments, whether in SMT production lines or other electronics assembly sectors.

Our team at PassionIOT has developed this technology with a deep understanding of the challenges faced in modern electronics manufacturing. The accurate counting of tiny components is often a bottleneck that can cause delays and increased operational costs. By incorporating X-ray component counting into our intelligent warehousing systems, we provide a robust tool that ensures real-time inventory accuracy, ultimately helping manufacturers maintain higher productivity and reduce unnecessary expenditures.

Reliable Storage for Solder Paste to Maintain Quality

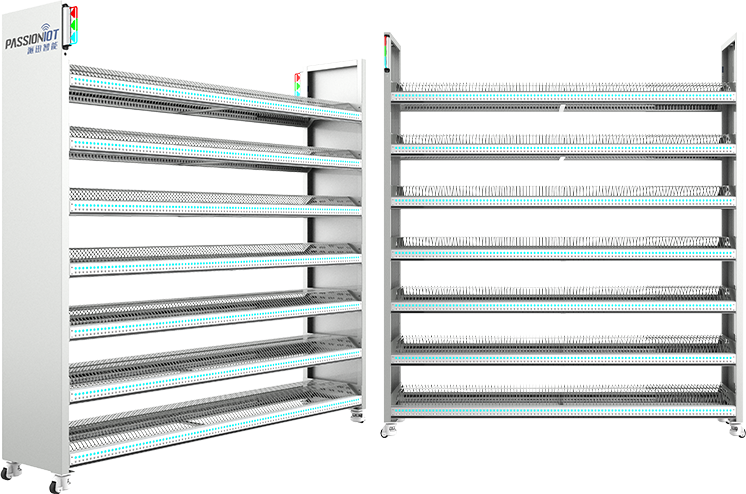

Alongside component management, we recognize the importance of proper solder paste storage in electronic assembly. The quality and consistency of solder paste directly influence the final product’s reliability and performance. At PassionIOT, we provide specialized solder paste storage solutions designed to maintain optimal conditions such as temperature and humidity control. Our storage systems ensure that solder paste remains fresh and stable, preventing degradation that could cause defects during soldering processes.

Proper solder paste storage is a vital part of the overall manufacturing process that is sometimes overlooked. Improper handling or storage of solder paste can lead to issues such as solder joint failures or uneven solder application. By offering advanced solder paste storage solutions, PassionIOT helps manufacturers preserve the integrity of their solder materials, which contributes significantly to reducing rework and scrap rates, as well as improving overall product quality.

Conclusion

We believe that integrating precise technologies like X-ray component counting and effective solder paste storage is vital to advancing smart manufacturing. At PassionIOT, our commitment to delivering intelligent storage and management solutions supports the evolving needs of electronic manufacturers. By focusing on these critical areas, we help businesses improve operational efficiency and product quality without unnecessary downtime or errors.

Our expertise in smart warehousing, including specialized products such as the Smart Vertical Carousel, Smart Vertical Lift Module, and SMD smart warehouses, reinforces our position in the industry, providing tailored solutions that meet diverse manufacturing demands. With continuous innovation and dedication to quality, we at PassionIOT aim to empower manufacturers to embrace smarter, more efficient production methods that respond to the challenges of today’s electronic manufacturing landscape.