In the rapidly changing world of manufacturing, accuracy and efficiency are more important than ever. At PassionIOT, we understand these demands and have integrated advanced X-ray technology into our smart storage solutions to support modern production environments. Our focus on innovation has led us to develop the X-ray component counter, a device designed to enhance inventory management and support streamlined production processes in electronics manufacturing and beyond. This technology helps to improve not only the accuracy but also the overall reliability of component tracking throughout the supply chain.

Enhancing Storage Accuracy with X Ray Component Counter

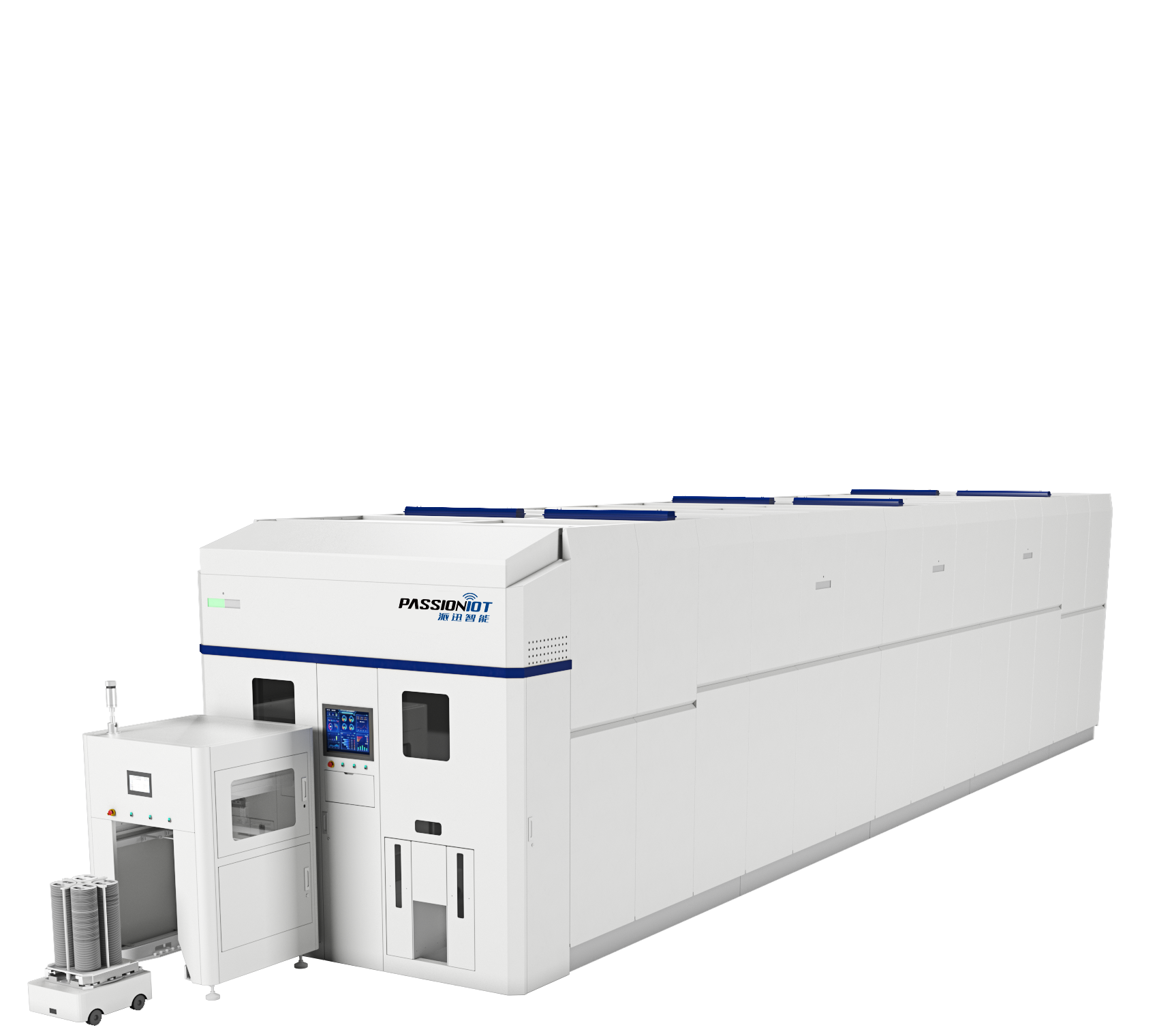

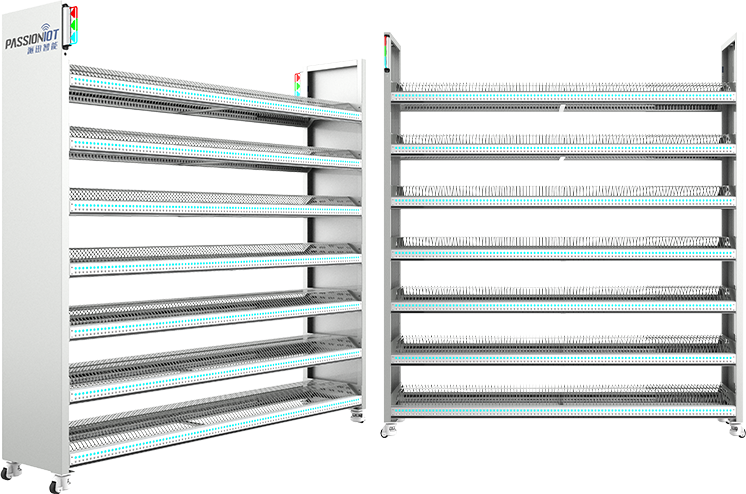

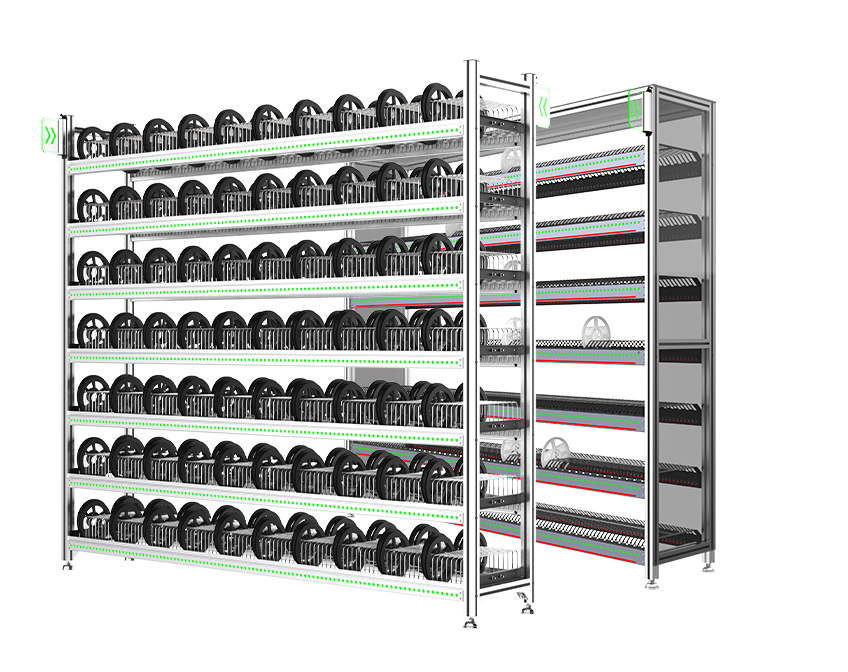

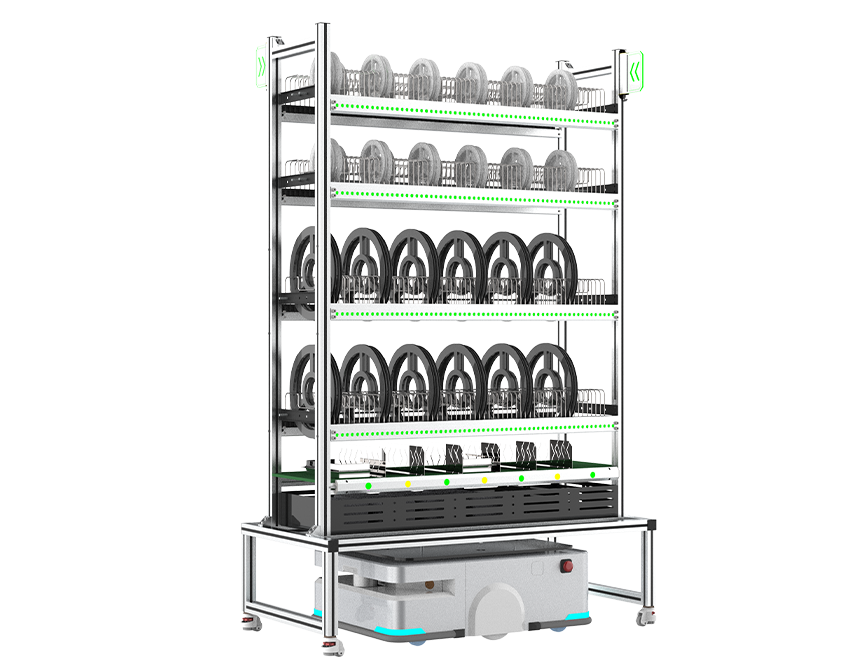

One of the persistent challenges in electronics manufacturing is maintaining precise inventory control, especially for small and fragile parts such as Surface Mount Devices (SMDs). Manual counting methods are often time-consuming and prone to human error, which can lead to production delays or quality issues. Our X-ray component counter leverages sophisticated X-ray technology to automatically count reel components with high precision. By capturing detailed images and analyzing them with intelligent algorithms, this technology enables real-time and accurate monitoring of component quantities. This reduces the need for manual checks, minimizes errors, and allows line-side storage operations to run smoothly. Additionally, when paired with our smart vertical carousel and vertical lift modules, the X-ray component counter provides an integrated solution that improves traceability and helps reduce equipment downtime, leading to a more efficient manufacturing process.

Versatile Applications Across Industries

Although initially designed for SMT line storage within electronics manufacturing, the use of X-ray technology through our X-ray component counter extends well beyond this niche. Many industries that require detailed inventory control and stringent quality assurance can benefit from this technology. For example, semiconductor manufacturing, medical device production, and other high-precision fields all face similar challenges in component counting and storage management. By combining this counting technology with our versatile vertical storage equipment, we offer adaptable solutions that fit various production environments. This flexibility helps companies optimize warehouse management, reduce waste, and increase overall operational efficiency.

Commitment to Innovation and Intelligent Manufacturing

At PassionIOT, we are committed to supporting our clients with solutions that reflect the future of manufacturing—where smart automation and data-driven processes are standard. The incorporation of X-ray technology in our products, particularly the X-ray component counter, exemplifies our approach to meeting real-world challenges through innovation. By providing reliable and intelligent systems, we help manufacturers maintain high standards of accuracy and efficiency, essential for staying competitive in today’s market. We continuously invest in research and development to ensure our solutions evolve alongside emerging industry needs and technologies.

Conclusion

Embracing advanced technologies such as X-ray technology is critical to improving manufacturing accuracy and efficiency. Our X-ray component counter stands as a testament to how innovative solutions from PassionIOT can address complex challenges in inventory management and production workflows. As we move forward, we remain dedicated to enhancing our product offerings to better serve a wide range of industries, helping our clients achieve smarter, more flexible, and more reliable manufacturing operations.