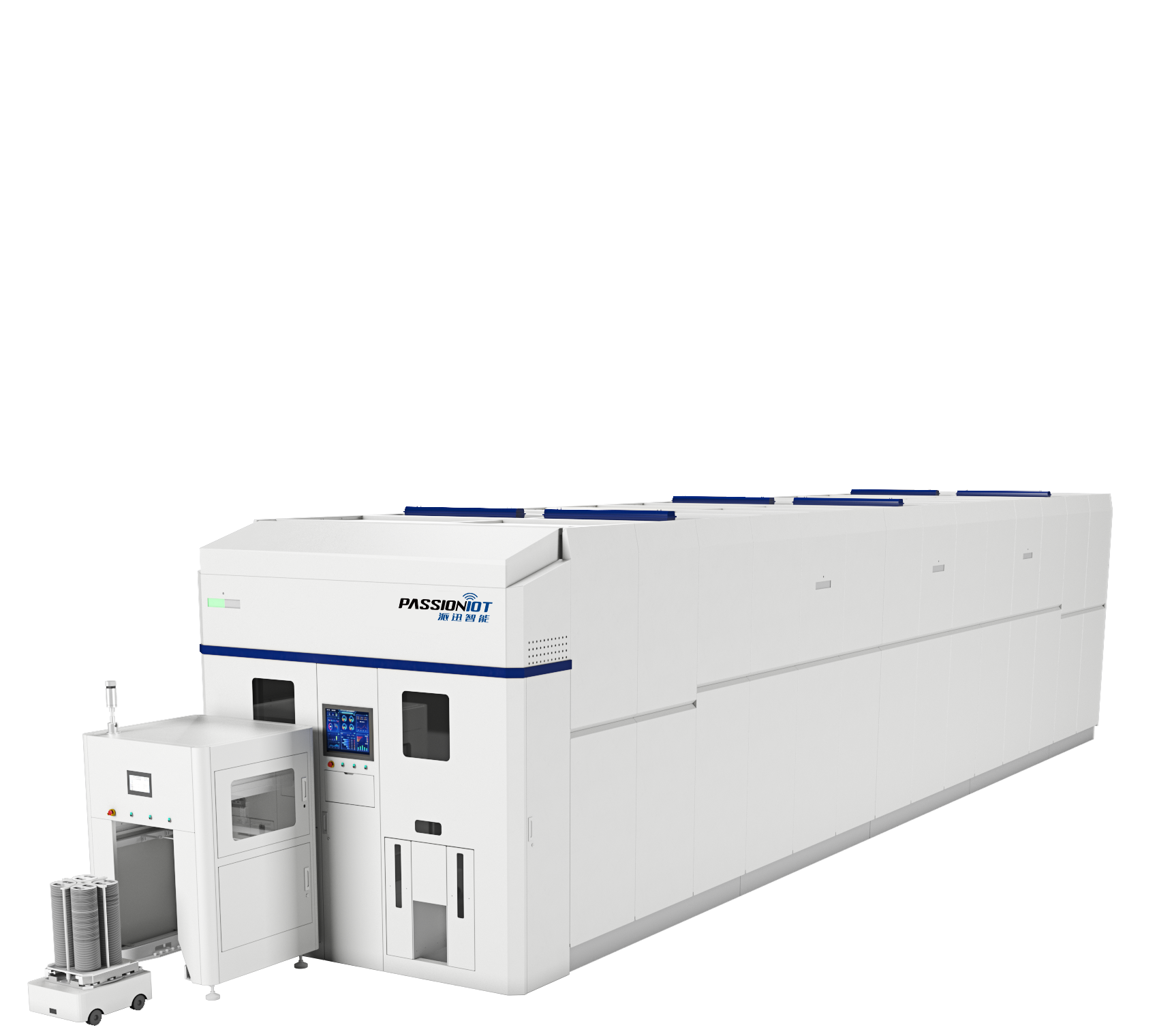

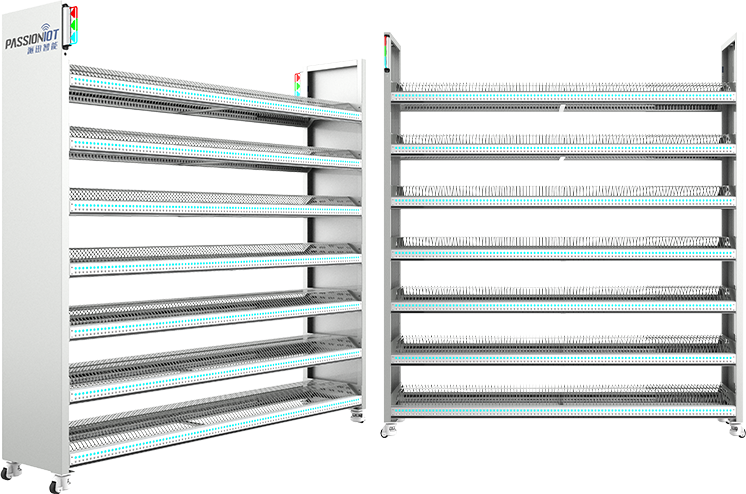

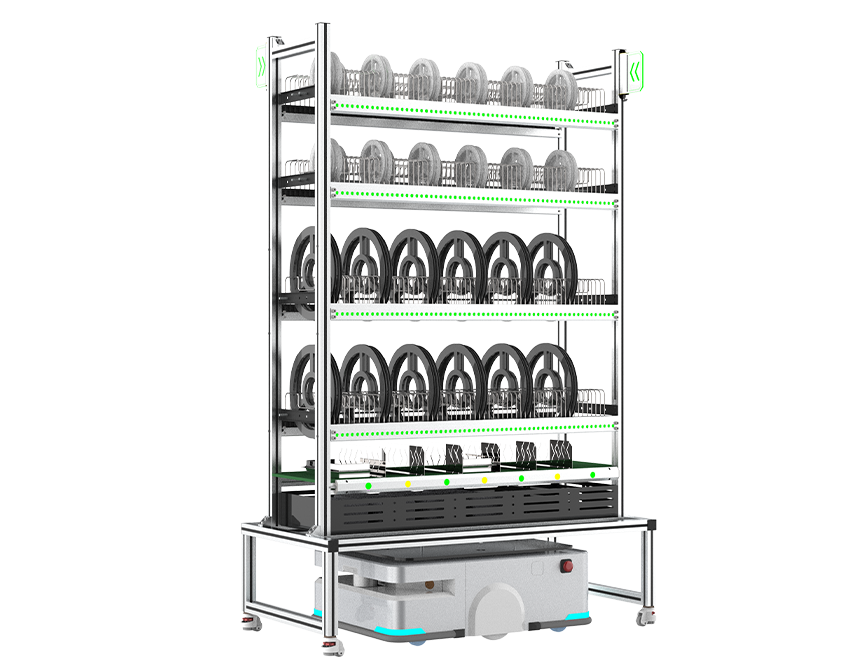

In the electronics manufacturing industry, precise material management is a key factor in ensuring consistent product quality and smooth production processes. At PassionIOT, we dedicate ourselves to developing intelligent solutions that support manufacturers in achieving this precision. Among our innovative technologies, the X-ray reel counter stands out as an effective tool for accurate reel counting in SMT production lines and beyond. Our extensive experience in smart storage and material handling enables us to deliver solutions tailored to the complex demands of modern factories, helping reduce human errors and improve operational efficiency.

Improving Production Line Accuracy with the X Ray Reel Counter

The X-ray reel counter we offer is designed to integrate seamlessly into existing production workflows, enabling continuous, real-time counting of reels without causing disruptions. Unlike traditional counting methods, such as manual visual checks or optical sensors which can be affected by environmental conditions like dust, lighting, or reel positioning, our X-ray technology provides a highly reliable and consistent counting mechanism. This reliability helps minimize the risk of production delays caused by incorrect material counts or unexpected shortages. Additionally, the system is flexible enough to handle various reel sizes and materials, making it a versatile choice for manufacturers across different industries.

The Importance of SMD Reel Counter X-Ray Technology in Modern Manufacturing

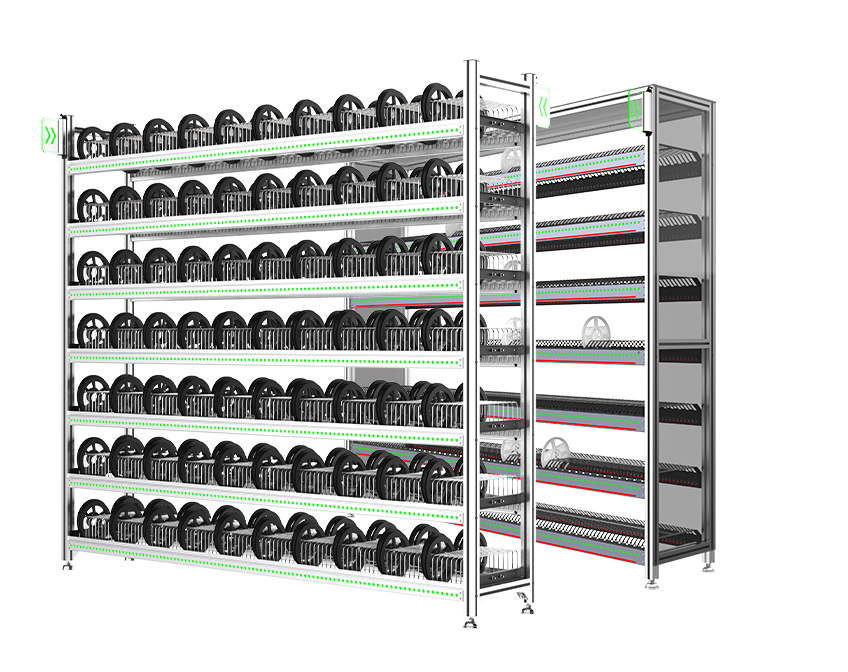

Surface-mount devices (SMD) are the core components in many electronic assemblies, and their precise tracking is critical. We focus heavily on the SMD reel counter X-ray technology because it directly addresses the unique challenges involved in counting these components on reels. While SMT refers to the mounting process, SMD identifies the components themselves, which are usually delivered on reels to production lines. Our SMD reel counter X-ray system employs advanced imaging and analysis to accurately determine the quantity of components remaining on each reel, reducing the chance of human error that can occur with manual counting methods. This precise data allows manufacturers to maintain better inventory control, optimize material ordering, and support just-in-time production strategies, all of which contribute to lowering operational costs and improving efficiency.

Conclusion

At PassionIOT, we see intelligent material handling as a foundation for smarter manufacturing processes. Our ongoing investment in technologies like the X-ray reel counter and SMD reel counter X-ray reflects our commitment to helping manufacturers gain greater control over their production materials. By implementing these solutions, companies can expect enhanced accuracy in reel counting, better visibility into inventory levels, and reduced risks of production interruptions due to material mismanagement. We continue to innovate and refine our offerings to meet the evolving needs of the electronics and semiconductor sectors, ensuring that our customers remain competitive in an increasingly complex market.