Efficient labeling is an essential part of modern manufacturing and logistics operations. Ensuring labels are applied accurately and swiftly contributes directly to productivity and quality control. Implementing an automated labeling machine in production lines helps reduce manual labor, decrease errors, and speed up the entire process. Companies across diverse industries are recognizing the benefits of automating labeling tasks to maintain consistency and improve workflow efficiency.

Precision and Versatility of Automatic Labeling Machines

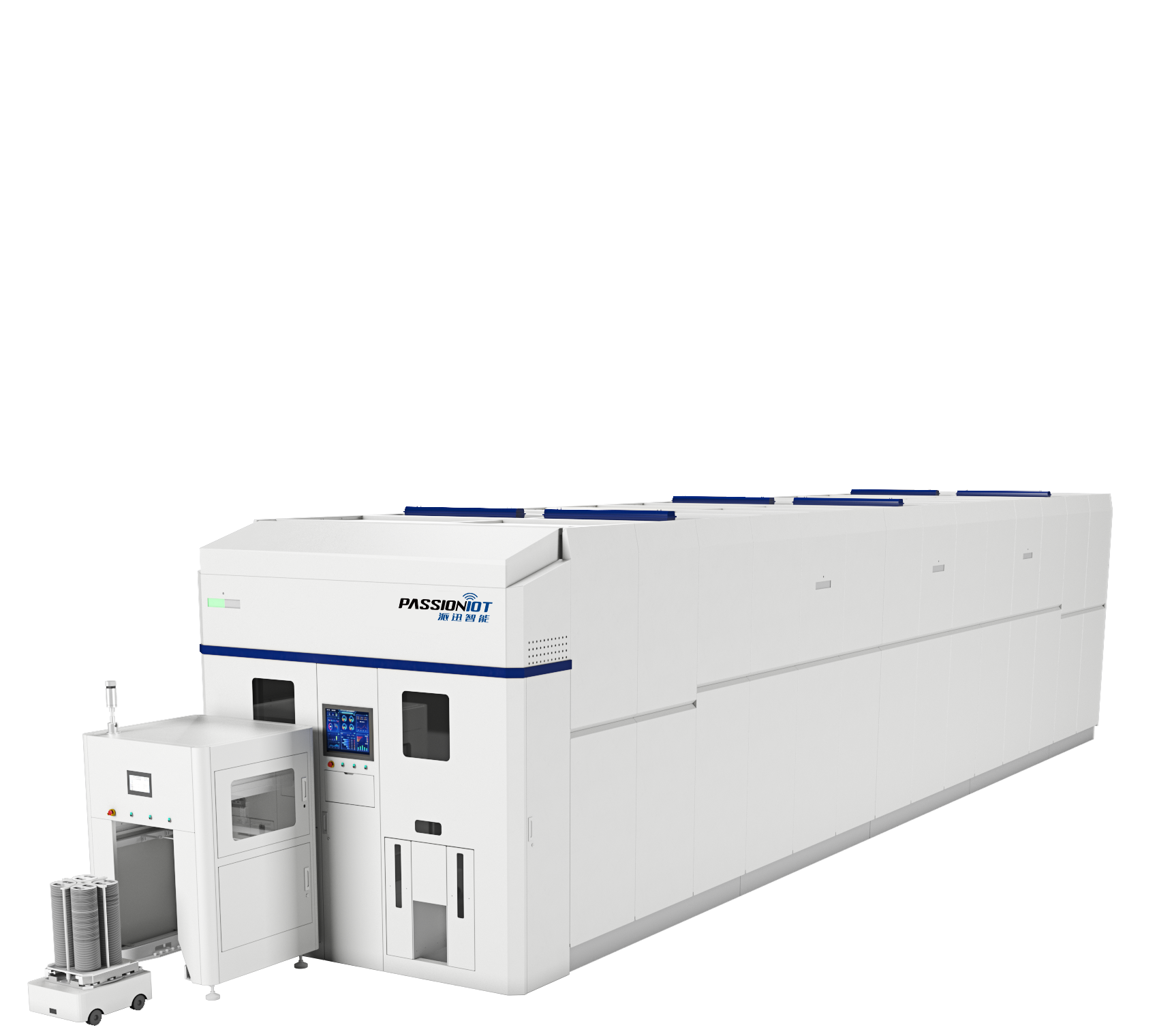

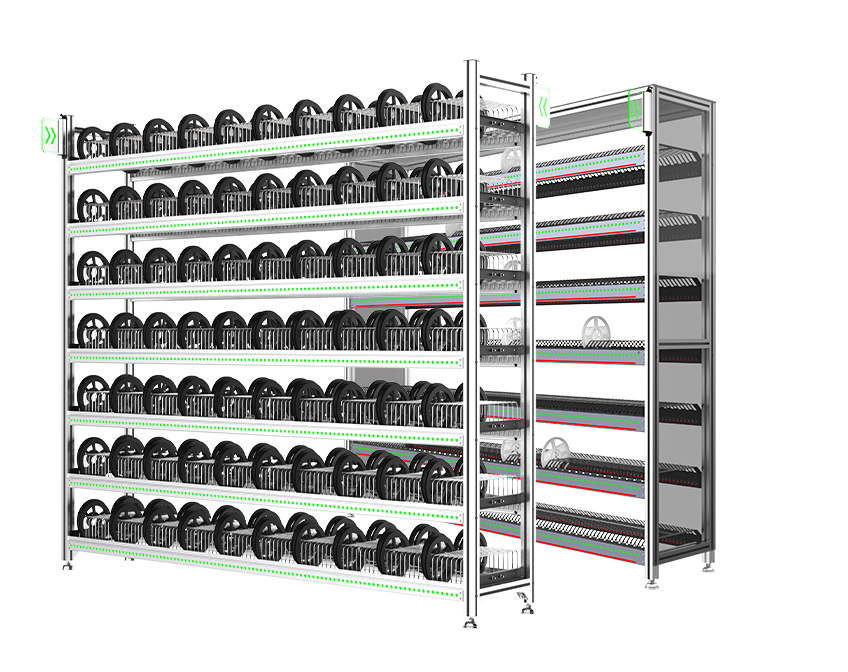

One key advantage of using an automatic labeling machine is its ability to handle a wide variety of label types and product shapes with high precision. This capability is especially critical in electronics manufacturing and semiconductor production, where labels must be applied correctly on small and delicate components. Here, PassionIOT provides tailored solutions designed to meet these specialized requirements. Their labeling machines seamlessly adapt to the complexities of SMT (Surface Mount Technology) lines and semiconductor storage workflows, such as those involving SMD components and wafer storage. This flexibility allows manufacturers to maintain strict quality standards while improving throughput.

The technology behind these machines includes advanced sensors, automated adjustments, and user-friendly interfaces that reduce downtime and setup times. This means production lines can run longer with fewer interruptions, ultimately lowering operational costs. By automating the labeling process, companies also improve traceability, which is vital for compliance and inventory management.

Seamless Integration Within Smart Manufacturing Ecosystems

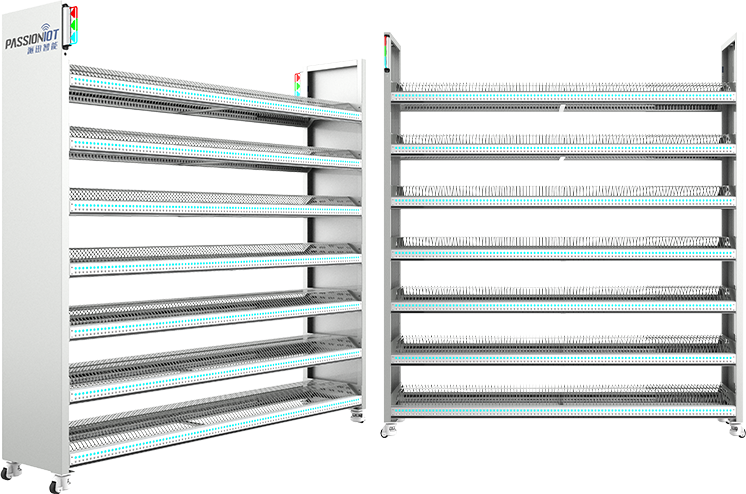

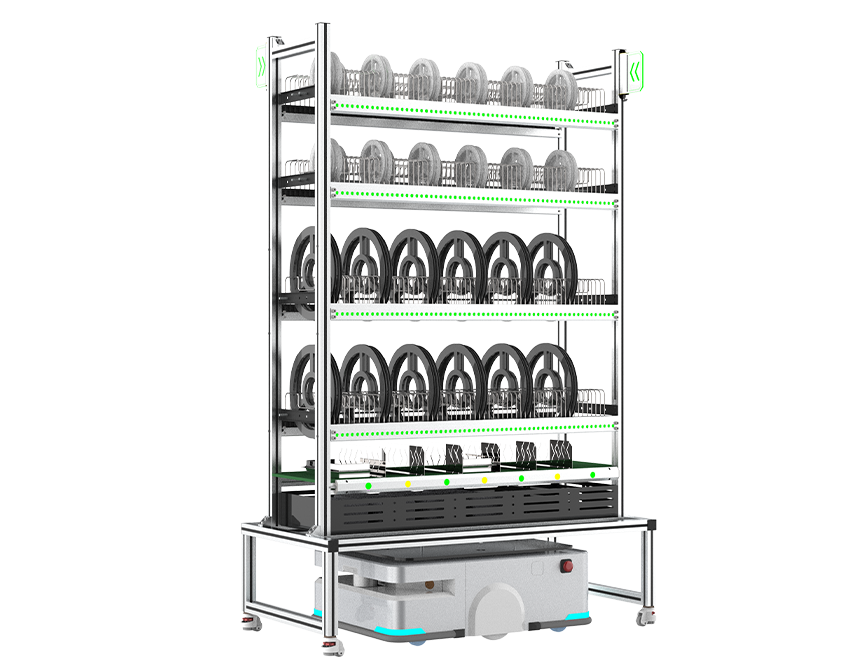

To fully realize the benefits of an automated labeling machine, it is crucial that the equipment integrates smoothly with other manufacturing systems. PassionIOT’s labeling solutions are designed with this integration in mind, working well alongside their Smart Vertical Carousel and Smart Vertical Lift Module storage units. These combined systems support a continuous flow of materials from storage to labeling and packaging, eliminating bottlenecks caused by manual handling.

The integration extends beyond physical connectivity—real-time monitoring and data analytics capabilities help production managers optimize workflows and detect issues early. This level of control enhances responsiveness and supports just-in-time manufacturing principles. By embedding automatic labeling machines into a broader smart factory environment, PassionIOT enables manufacturers to improve overall operational efficiency and scalability.

Conclusion

From our perspective at PassionIOT, investing in advanced automation technologies like the automatic labeling machine is key to staying competitive in today’s manufacturing landscape. These machines reduce labor intensity and improve accuracy, all while supporting flexibility in handling diverse product types. More importantly, they serve as integral components within a holistic smart manufacturing system, contributing to smoother processes and better resource utilization.

As market demands evolve, embracing automation and smart integration will be essential to meet production goals without compromising quality. We are committed to helping our customers achieve these objectives through reliable, adaptable, and intelligent labeling solutions tailored to their unique needs.