Manufacturing efficiency has become a critical focus in the electronics and semiconductor industries. We understand that integrating automation with intelligent storage systems is essential for maintaining competitiveness and meeting production demands. Among the advanced solutions we offer, the automated soldering machine and vertical carousel storage stand out as vital components in optimizing manufacturing workflows. These technologies help reduce manual labor, increase accuracy, and improve space utilization across diverse production environments.

Enhancing Production Quality with Automated Soldering Machine

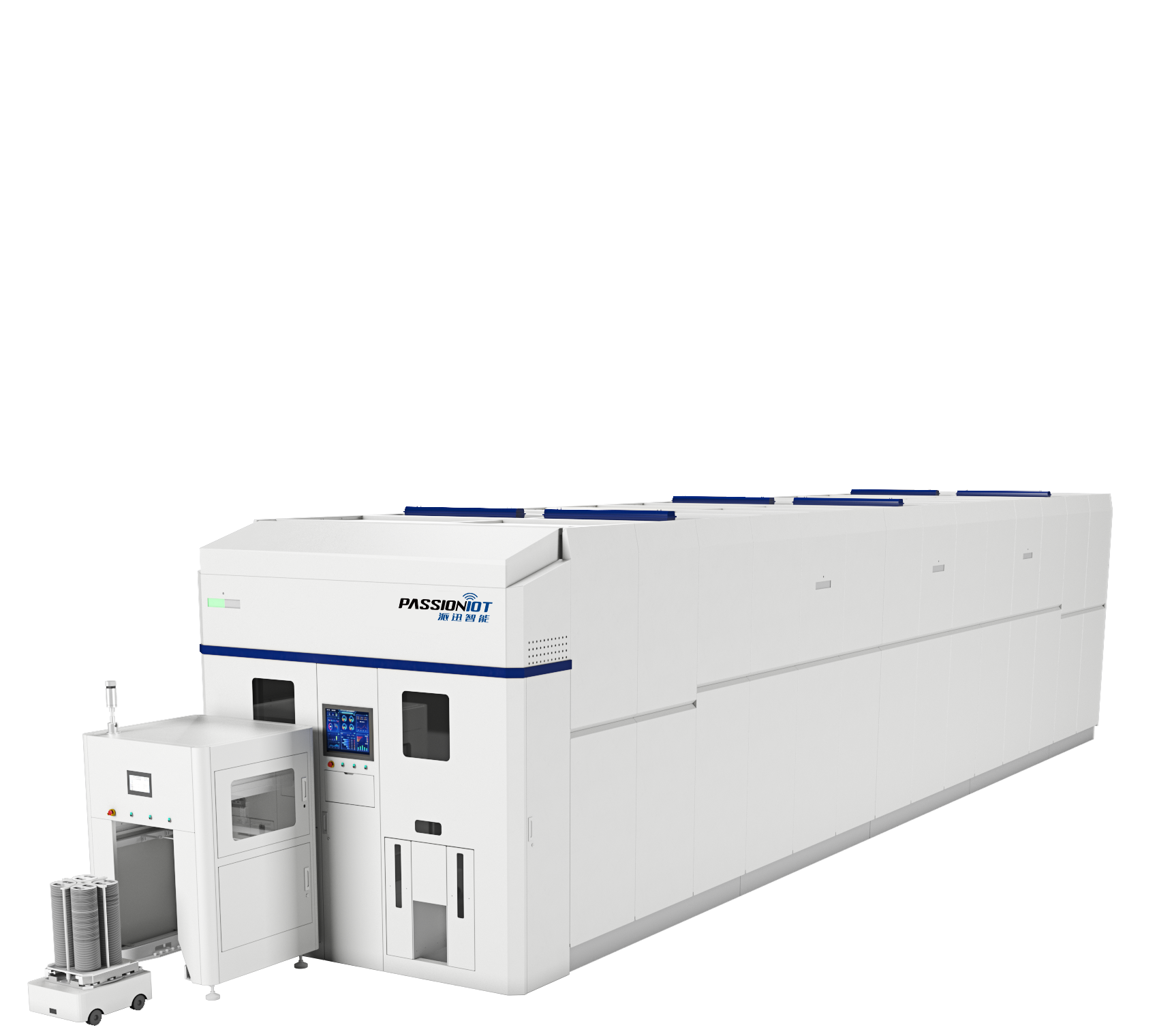

Precision soldering is a foundational process in Surface Mount Technology (SMT) assembly, where consistent joint quality impacts overall product reliability. In this area, PassionIOT delivers an automated soldering machine engineered to address common challenges in manual soldering processes. By leveraging robotics and smart control systems, our machine ensures consistent soldering speed and temperature, minimizing defects and material waste.

The implementation of the automated soldering machine reduces the dependence on manual skill, which can vary across operators. Instead, production lines benefit from repeatable and scalable soldering processes. This consistency not only improves throughput but also enhances product quality by maintaining uniform solder joints throughout large production batches. Our clients appreciate how this solution integrates seamlessly into existing SMT lines, allowing for flexible and continuous operation without major downtime.

Maximizing Storage Efficiency with Vertical Carousel Storage

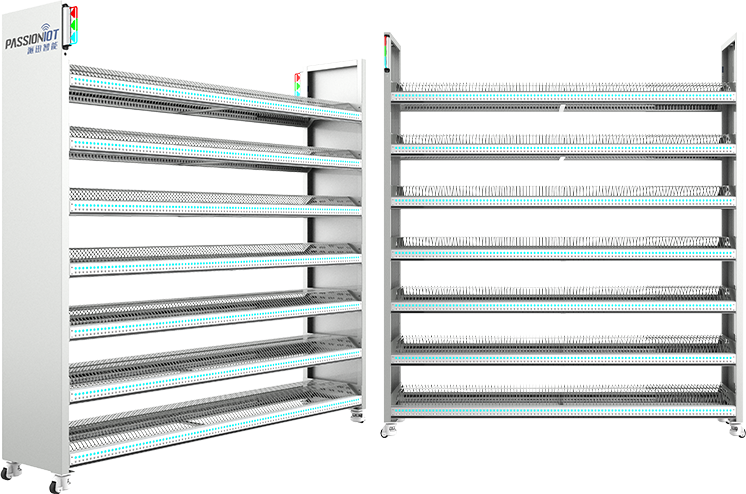

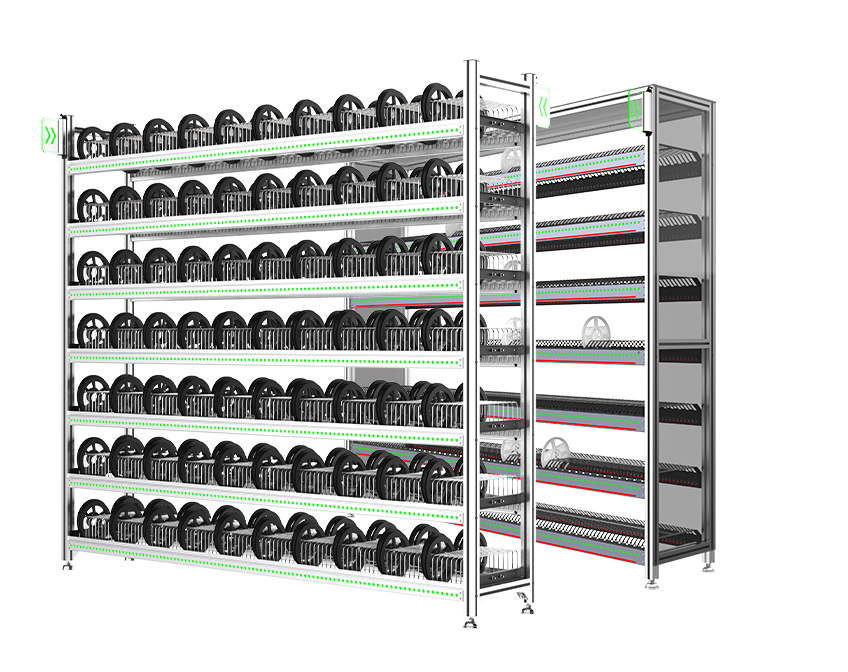

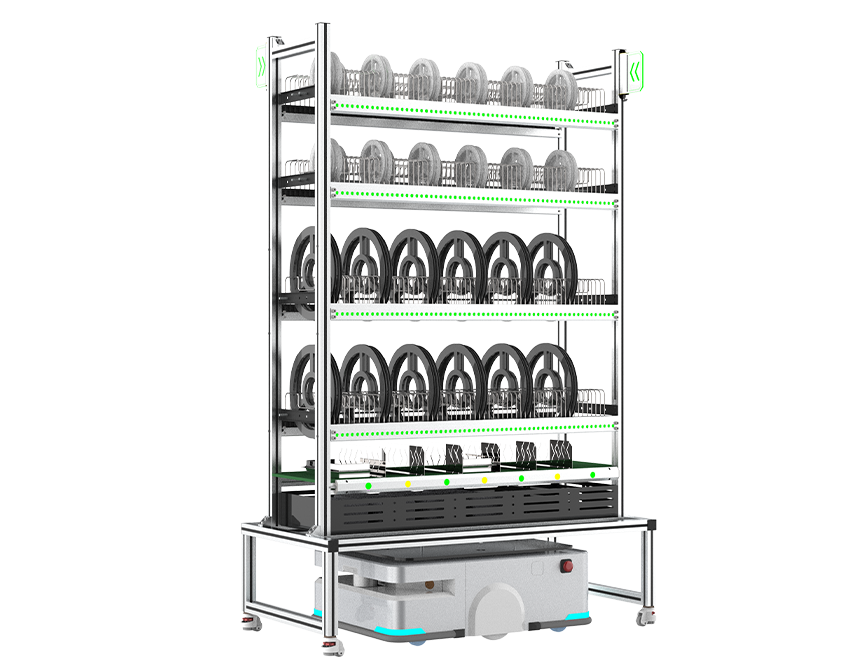

Proper inventory management is just as important as the production process itself. Storing components in an organized and accessible manner can drastically reduce downtime caused by searching and handling parts. The vertical carousel storage system offered by PassionIOT provides a space-saving and automated solution for managing small electronic components, solder paste, and even delicate semiconductor wafers.

This storage solution rotates shelves vertically, bringing the requested items directly to the operator, which saves floor space and enhances picking accuracy. Its modular design means it can be customized for various load capacities and sizes, making it adaptable to a wide range of industries beyond electronics manufacturing. By supporting just-in-time inventory approaches, the vertical carousel storage reduces excess inventory and improves material flow, contributing to a more efficient production cycle.

Conclusion

Our commitment at PassionIOT is to empower manufacturers with smart, scalable, and reliable equipment like the automated soldering machine and vertical carousel storage. These solutions work in tandem to improve production accuracy, minimize manual errors, and optimize storage management, creating smoother workflows and reducing overall costs.

Since our founding in 2014, we have continuously evolved our technologies to meet the complex needs of modern manufacturing environments. By choosing to implement these solutions, manufacturers can better respond to market demands, maintain consistent product quality, and improve operational efficiency. We believe that investing in such intelligent automation and storage systems is a key step toward achieving more agile and competitive manufacturing capabilities.