Efficient storage and material handling are critical factors in modern electronics manufacturing. One essential component to streamline these processes is the use of a reliable industrial reel rack. These racks provide an organized system for storing reels in surface mount technology lines, helping minimize downtime and material mismanagement. Alongside this, managing SMD solder paste properly plays a vital role in maintaining product quality and assembly consistency throughout the manufacturing process.

Enhancing Storage Solutions with Industrial Reel Rack

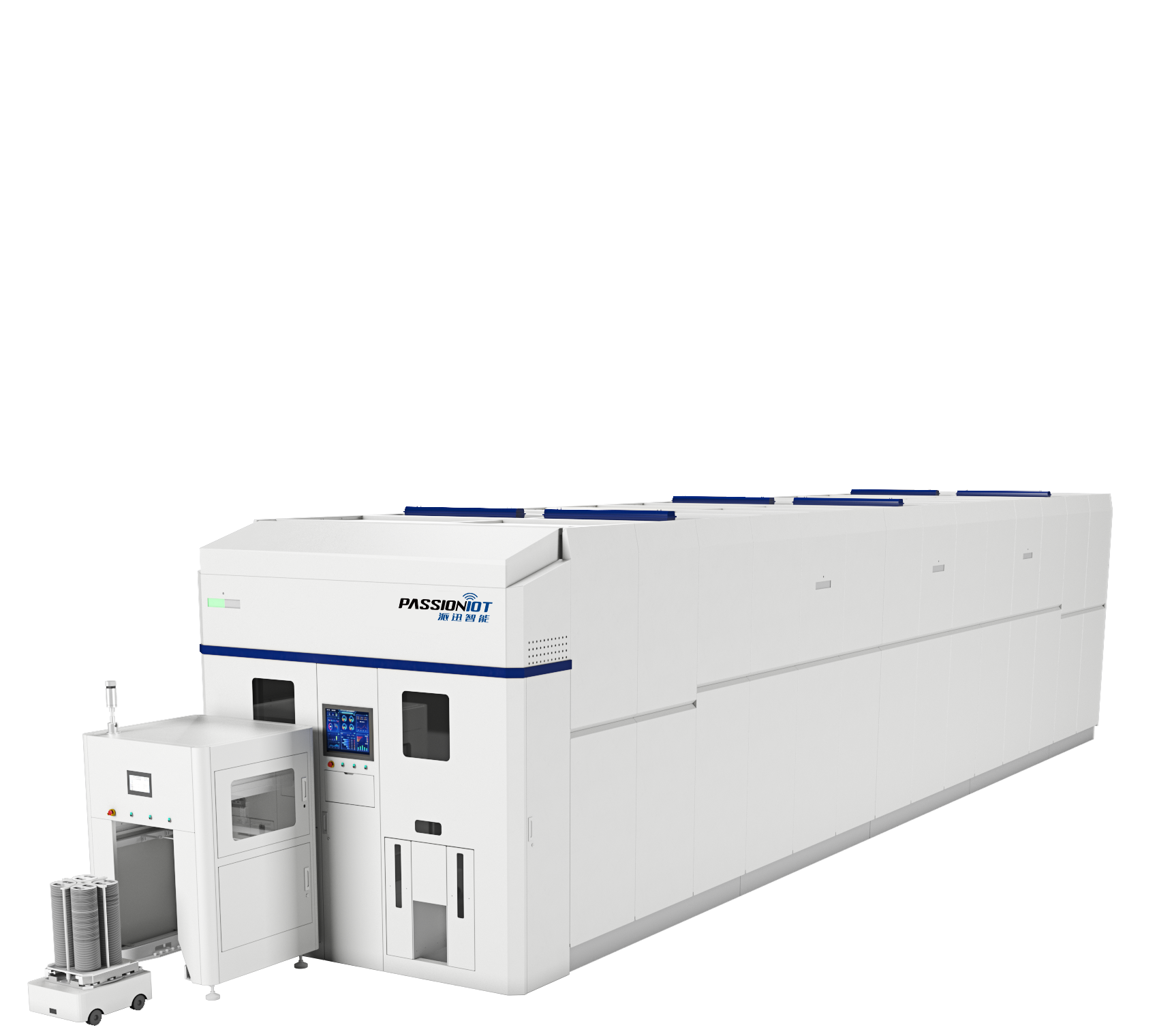

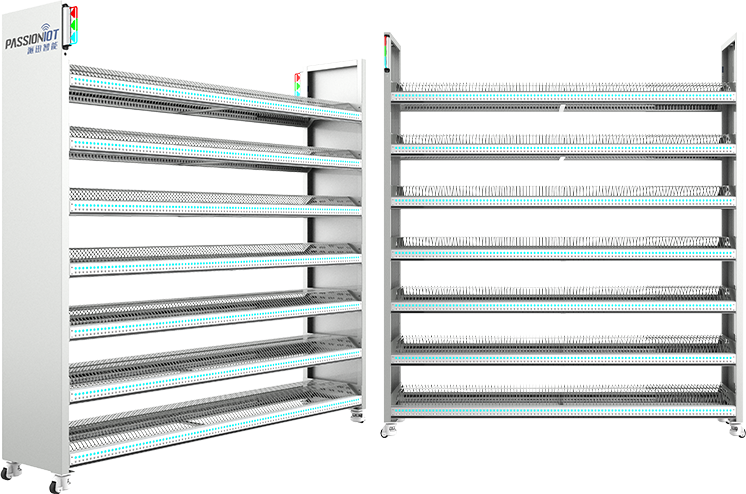

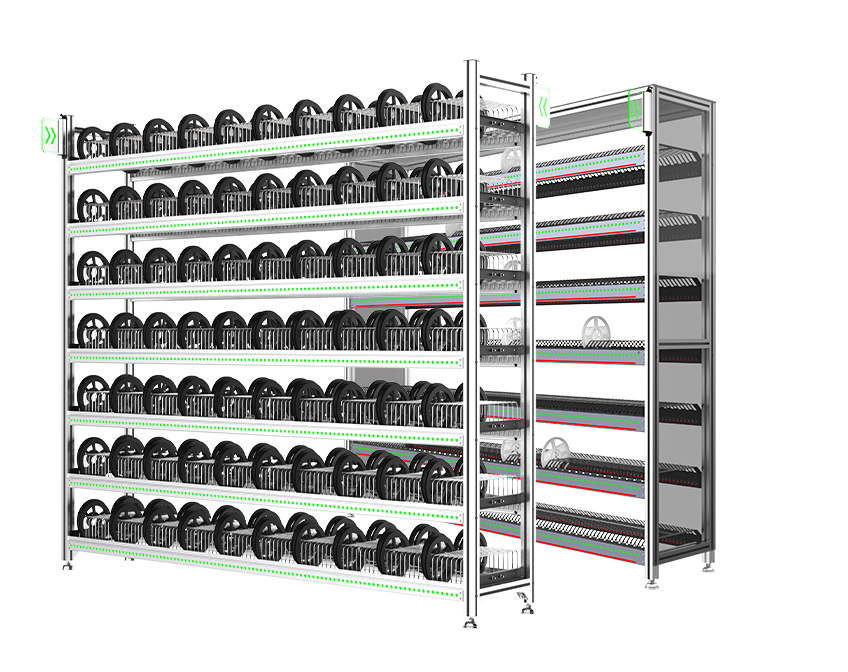

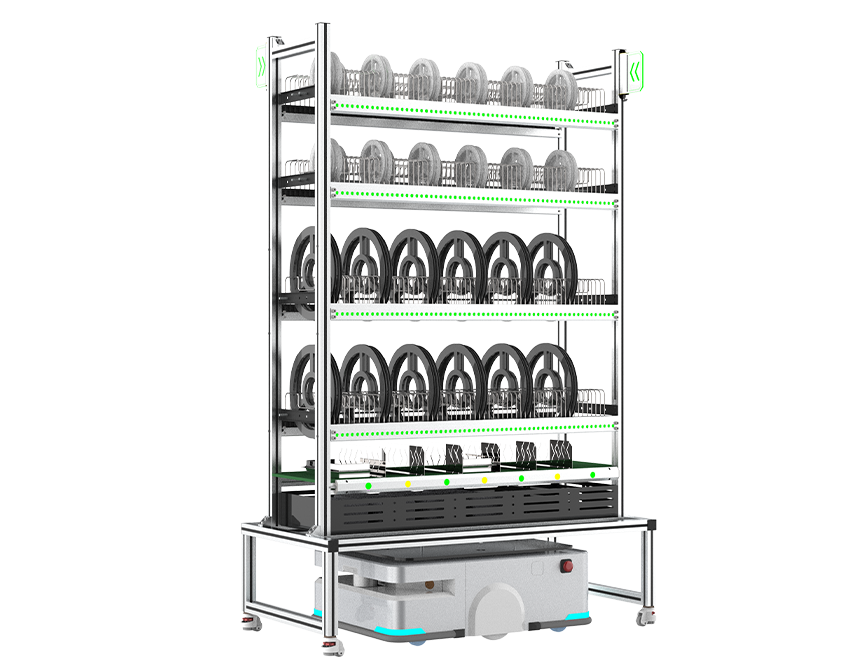

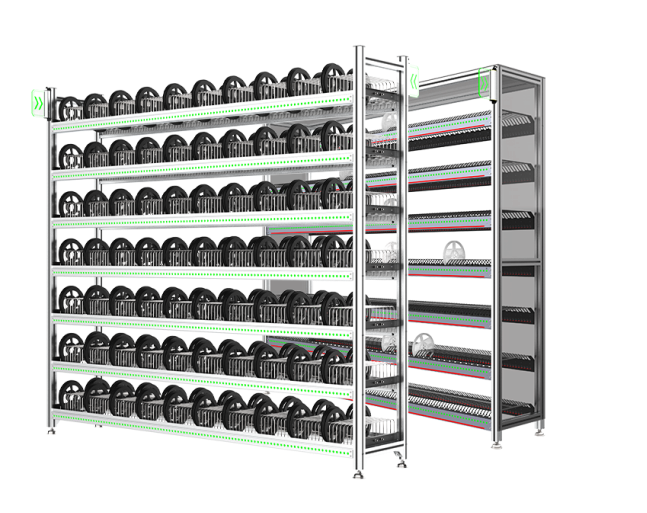

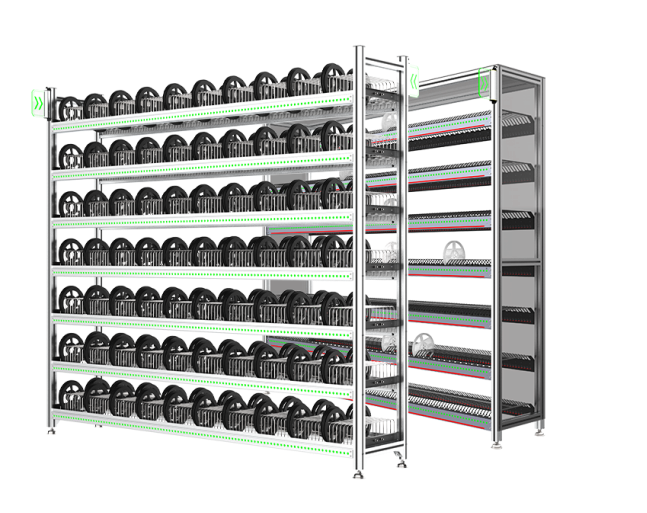

In the pursuit of smarter manufacturing, our team at PassionIOT has developed robust solutions centered around the industrial reel rack to support diverse production needs. The design of these racks ensures compatibility with various reel sizes, making them adaptable across different SMT production lines. With their strong construction and modular features, these racks optimize floor space while facilitating easy access to necessary components, significantly improving workflow efficiency.

The industrial reel rack also integrates seamlessly with automated inventory systems, enabling real-time monitoring and improving accuracy in material management. This integration supports the smooth operation of related equipment such as Smart Vertical Carousels and Vertical Lift Modules, which together form part of a comprehensive warehouse automation system. With this coordinated setup, production flow becomes more streamlined and less prone to interruptions, resulting in consistent manufacturing output.

Ensuring Quality through Proper SMD Solder Paste Handling

Another key element in electronic assembly is the careful management of SMD solder paste. Because this paste is highly sensitive to environmental factors such as temperature and humidity, it requires controlled storage conditions to preserve its chemical properties. Mishandling SMD solder paste can lead to poor solder joints, which negatively affect the durability and performance of electronic devices.

At PassionIOT, we focus on integrating advanced storage environments and monitoring techniques to maintain the optimal condition of SMD solder paste throughout the production cycle. This attention to detail not only enhances manufacturing reliability but also helps reduce material waste, contributing to cost-effective operations. Furthermore, promoting best practices in handling SMD solder paste aligns with our commitment to improving overall assembly quality and operational excellence in the electronics industry.

Conclusion

By integrating efficient industrial reel rack systems with specialized SMD solder paste management, we take a holistic approach to smart manufacturing. Our solutions help create smoother workflows, minimize errors, and ensure consistent production quality. The combination of intelligent storage solutions and careful material management underscores our dedication to providing adaptable, practical technologies that meet evolving industry challenges.

As manufacturing demands continue to grow, our commitment at PassionIOT remains focused on developing and refining products that support flexible, scalable, and efficient production environments. We believe that by continuously improving key components like the industrial reel rack and SMD solder paste handling, we empower manufacturers to achieve operational excellence and remain competitive in a fast-paced market.