In the rapidly evolving world of electronics manufacturing, managing solder paste effectively is a crucial challenge many factories face. At PassionIOT, we understand this complexity and are committed to providing smart, reliable solutions tailored for modern production environments. As a specialized solder paste manufacturer, we focus on delivering high-quality solder paste material management systems that optimize efficiency and reduce waste throughout the manufacturing process.

Precision and Reliability in Solder Paste Management

The role of solder paste in surface-mount technology (SMT) is vital, acting as the medium that secures electronic components onto printed circuit boards (PCBs). However, the handling and storage of solder paste material require precise control due to its sensitive nature and limited shelf life. As a dedicated solder paste manufacturer, we offer integrated management systems that ensure proper storage conditions and traceability, minimizing the risk of defects caused by degraded or mishandled paste.

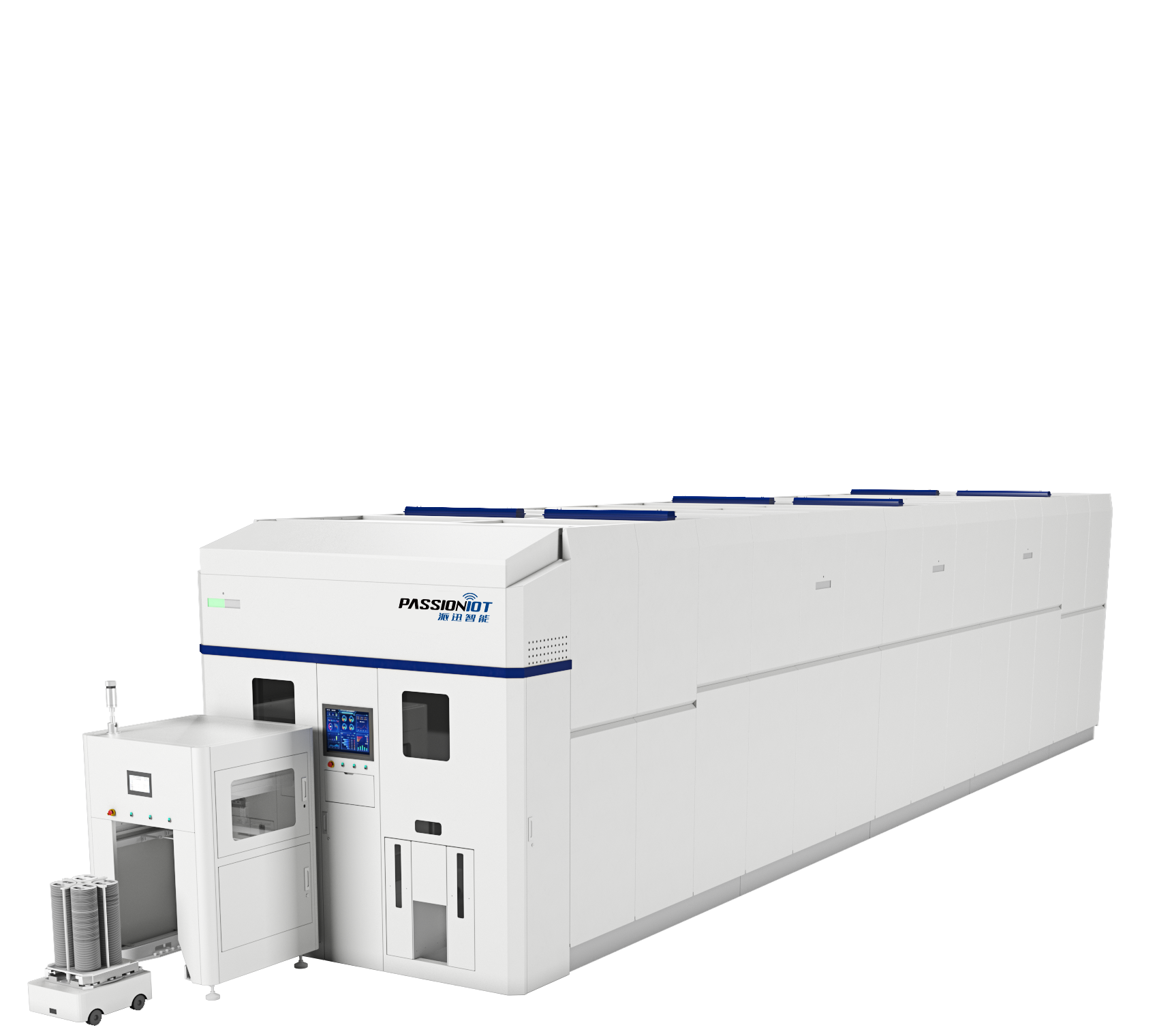

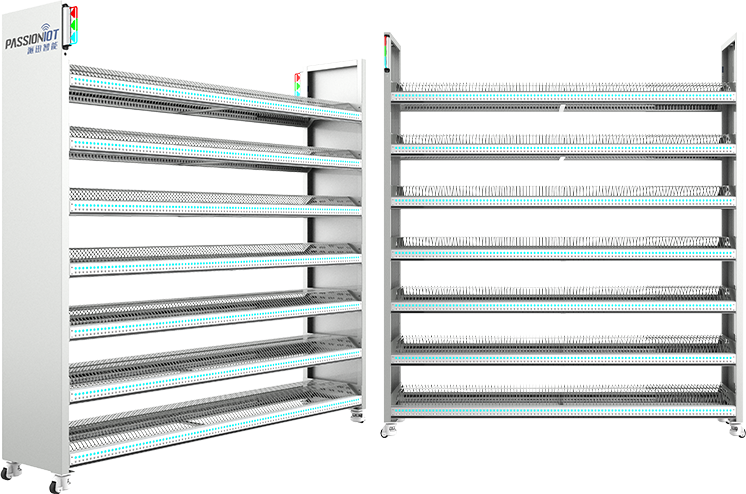

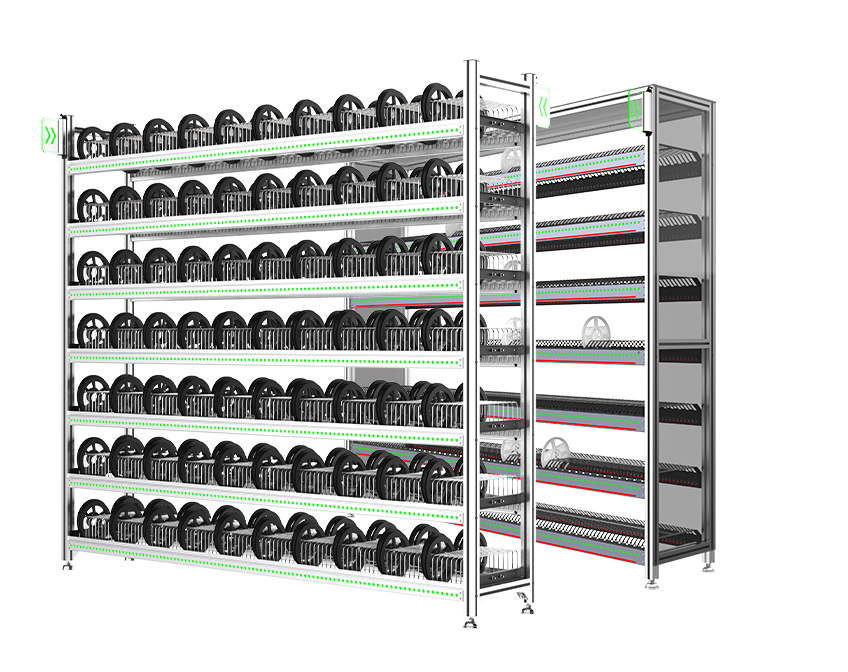

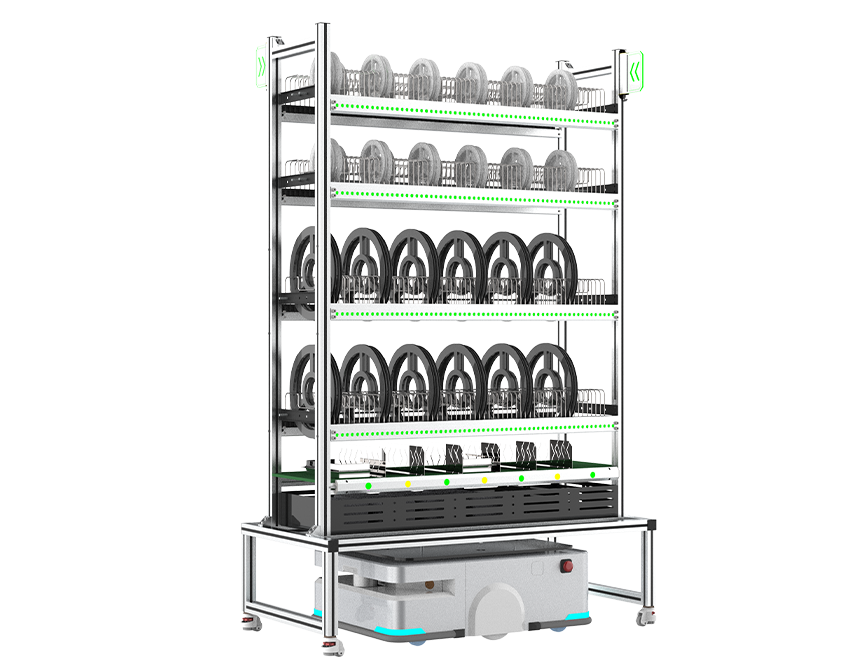

Our solutions, including the Smart Vertical Carousel and Smart Vertical Lift Module, provide automated storage options designed specifically for solder paste and related materials. These systems are engineered to maintain optimal temperature and humidity conditions, guaranteeing that the solder paste material remains stable and effective for use. By automating the storage and retrieval process, we also reduce manual errors and increase overall productivity on the production line.

Customized Solutions for Diverse Manufacturing Needs

We recognize that different manufacturing plants have unique requirements depending on their scale, product variety, and production speed. At PassionIOT, our approach is flexible, offering customizable systems that integrate seamlessly with existing workflows. Whether the need is for a compact solder paste manufacturer system suitable for smaller lines or a large-scale vertical carousel for extensive SMT production, our product lineup covers a wide spectrum.

In addition to the core storage solutions, we incorporate intelligent monitoring technologies that provide real-time data on solder paste material usage and inventory status. This capability enables manufacturers to plan procurement more accurately and avoid costly downtime due to material shortages. Our dedication to smart manufacturing practices helps our clients maintain consistent quality and adapt swiftly to market changes.

Conclusion

At PassionIOT, we are proud to contribute to the intelligent manufacturing revolution by focusing on essential components like solder paste management. As a knowledgeable solder paste manufacturer, we strive to improve manufacturing outcomes through advanced storage systems and precise material control. Our expertise in solder paste material solutions helps factories minimize waste, reduce operational risks, and maintain high-quality production standards.

We continue to innovate in this field, listening closely to our customers’ needs and applying cutting-edge technologies to our product offerings. By partnering with PassionIOT, manufacturers gain a trusted ally committed to enhancing efficiency and reliability in their SMT processes. Our goal is to help every client build a smarter, more responsive manufacturing environment for today and the future.