In the ever-changing landscape of business operations, finding effective ways to optimize internal logistics has become a strategic imperative for enhancing efficiency. We recognize that it is essential to save space and cut costs, particularly when managing our warehousing systems. By exploring innovative warehousing solutions, we can significantly improve our operational workflows while maximizing resources.

Space Optimization through Advanced Warehousing Solutions

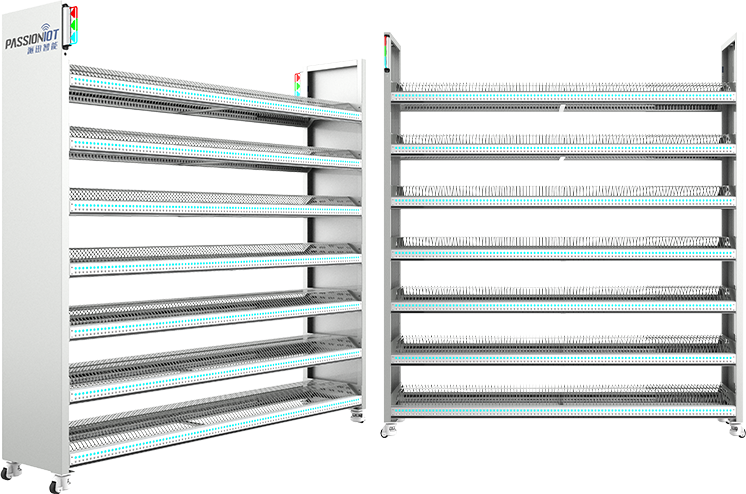

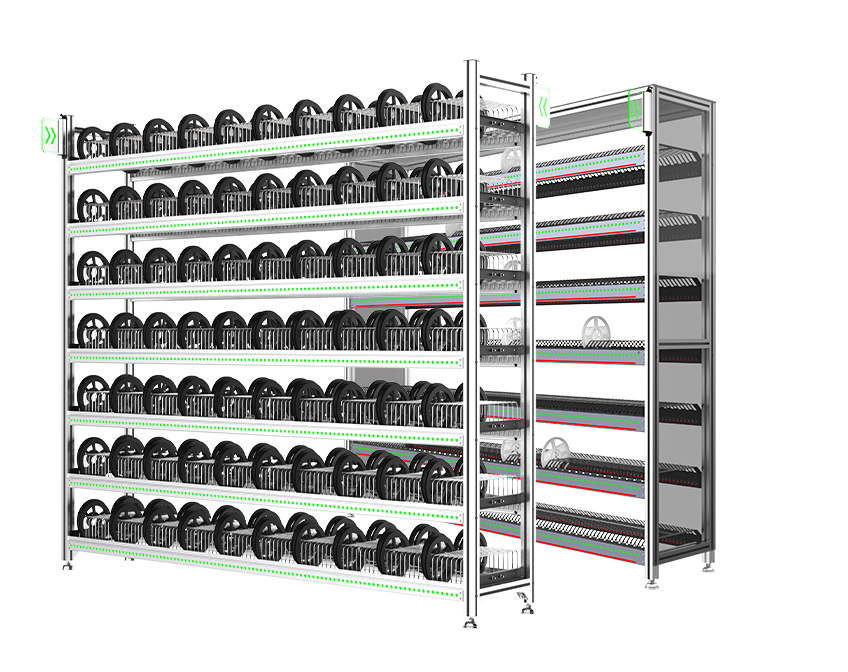

One of the key advantages of implementing advanced warehousing storage solutions is the ability to save space effectively. Through complete dense storage methodology, we can significantly increase our capacity without the need for extensive physical expansion. This approach allows us to utilize vertical space more efficiently, resulting in optimized storage layouts and improved inventory management.

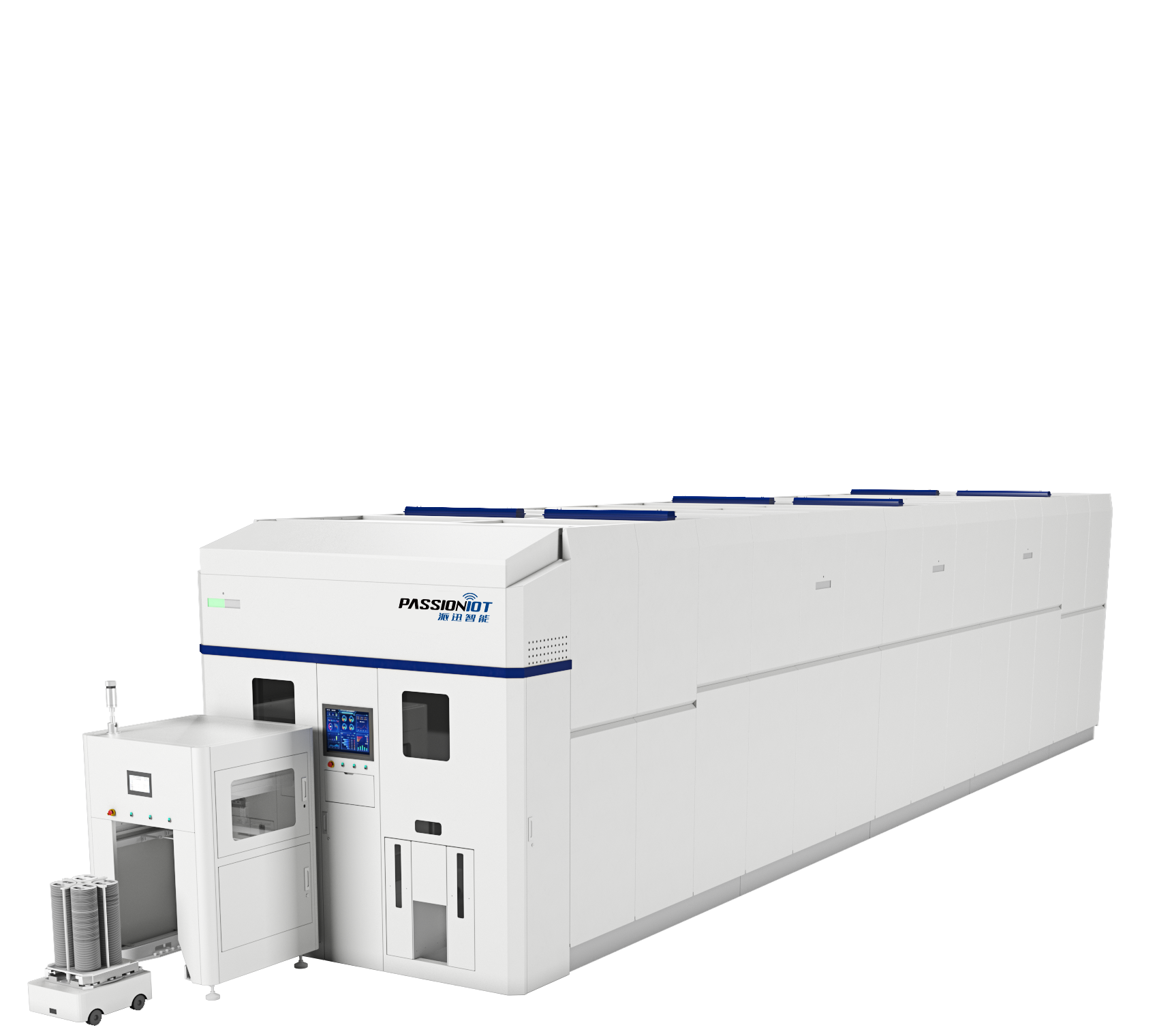

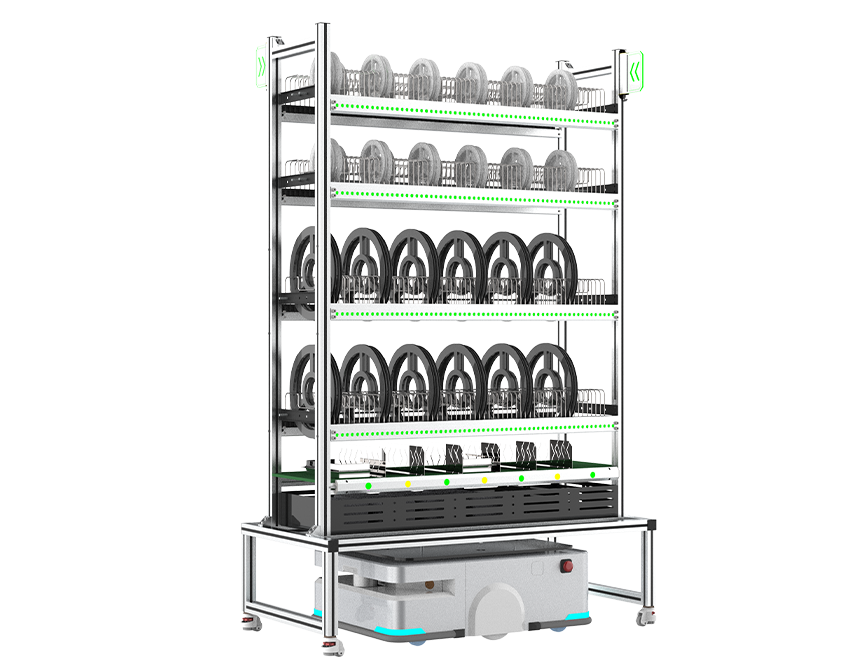

We have witnessed firsthand how intelligent material warehouses and smart shelving systems can transform our storage capabilities. By adopting these warehousing solutions, we not only enhance our storage efficiency but also create a streamlined environment that reduces clutter and fosters productivity. The integration of technologies such as convergence and sorting systems ensures that our goods are organized and easily accessible, promoting swift retrieval when needed.

Cost Reduction Strategies in Internal Logistics

Alongside space-saving benefits, cutting costs is another critical aspect of our internal logistics strategy. Effective warehouse location planning plays a pivotal role in ensuring that our operations are economical. By strategically designing our storage layouts, we can reduce labor costs associated with inventory handling and retrieval processes.

With PassionIOT's innovative warehousing storage solutions, we are able to implement intelligent trackless Automated Guided Vehicles (AGVs). These vehicles enhance our operational flexibility by moving materials efficiently within the warehouse. By automating material handling tasks, we decrease reliance on manual labor, which both saves costs and minimizes the likelihood of errors in our logistics processes.

Moreover, the synergy created through our intelligent warehousing solutions allows for better cooperation between production and storage. By breaking down information silos in the production process, we can streamline workflows and improve coordination across departments. This not only decreases operational inefficiencies but also supports a culture of continuous improvement.

Conclusion: A Pathway to Operational Excellence

As we navigate the complexities of modern logistics, embracing internal logistics solutions becomes a crucial step toward achieving operational excellence. By focusing on warehousing solutions that save space and cut costs, we set the foundation for sustainable growth in our business.

The implementation of efficient warehousing storage solutions helps us maximize our resources while minimizing expenses, ultimately contributing to our bottom line. With PassionIOT’s commitment to providing innovative logistics technology, we are better equipped to tackle the challenges of the industry and enhance our overall efficiency. Through these strategic improvements, we position ourselves for continued success and adaptability in an ever-evolving market landscape.