At PassionIOT, we understand the critical role that material flow plays in modern manufacturing and warehousing operations. Since our founding in 2014, we have been committed to delivering intelligent manufacturing solutions that improve how materials move through production lines and storage areas. Our expertise is grounded in developing tailored systems that seamlessly integrate with existing workflows, helping businesses enhance operational efficiency without disruption. Leveraging cutting-edge technology, we focus on optimizing material flow and conveyor systems to create a smarter, more agile manufacturing environment that responds to the complexities of today's industries.

Enhancing Operations Through Intelligent Material Flow and Conveyor Systems

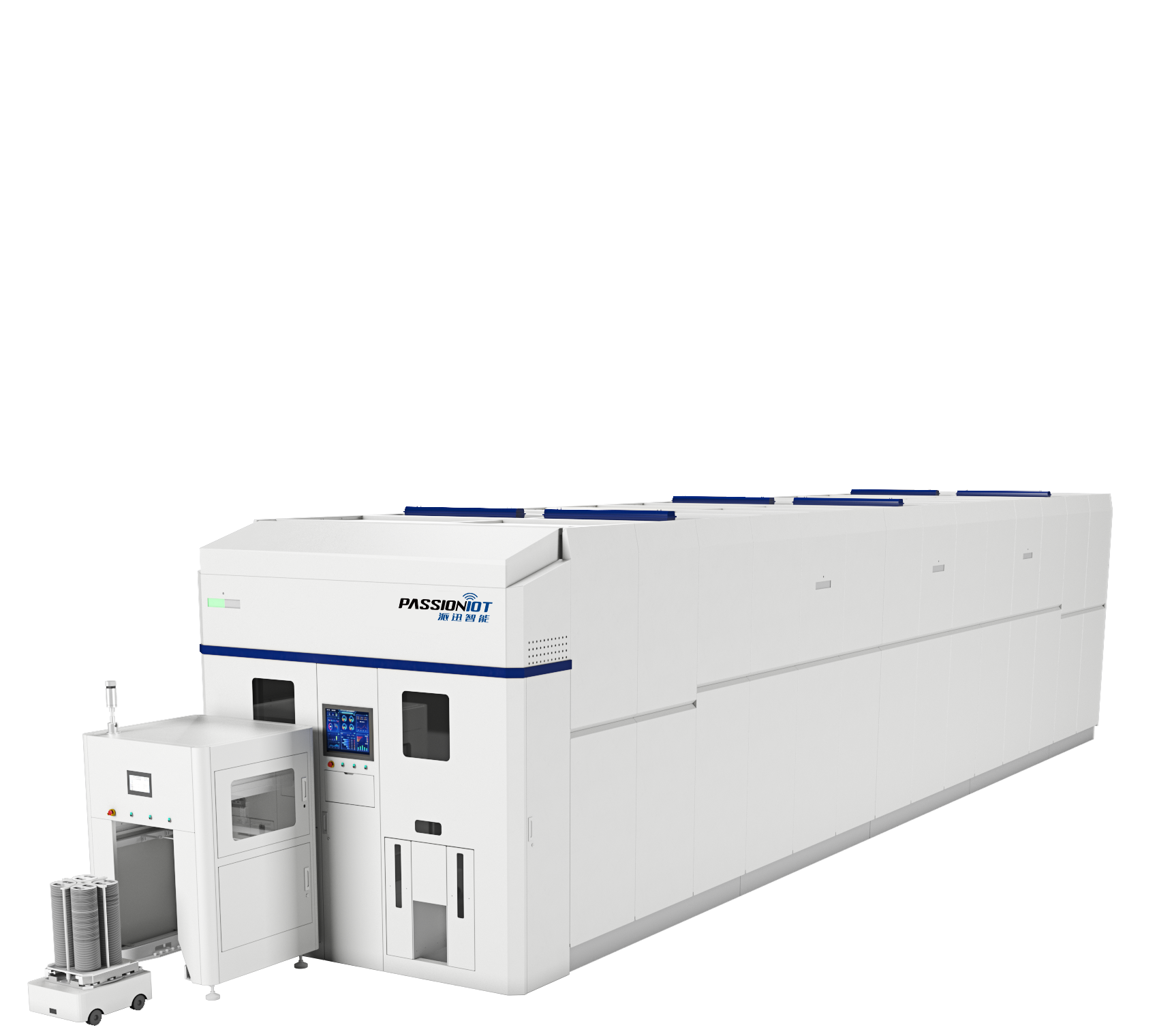

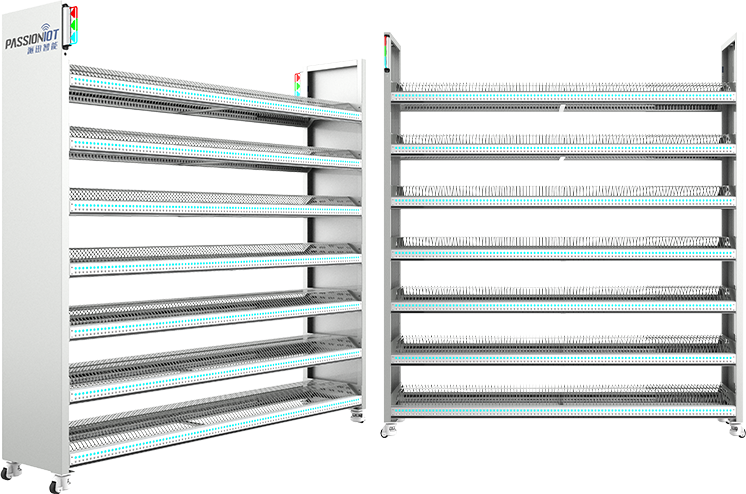

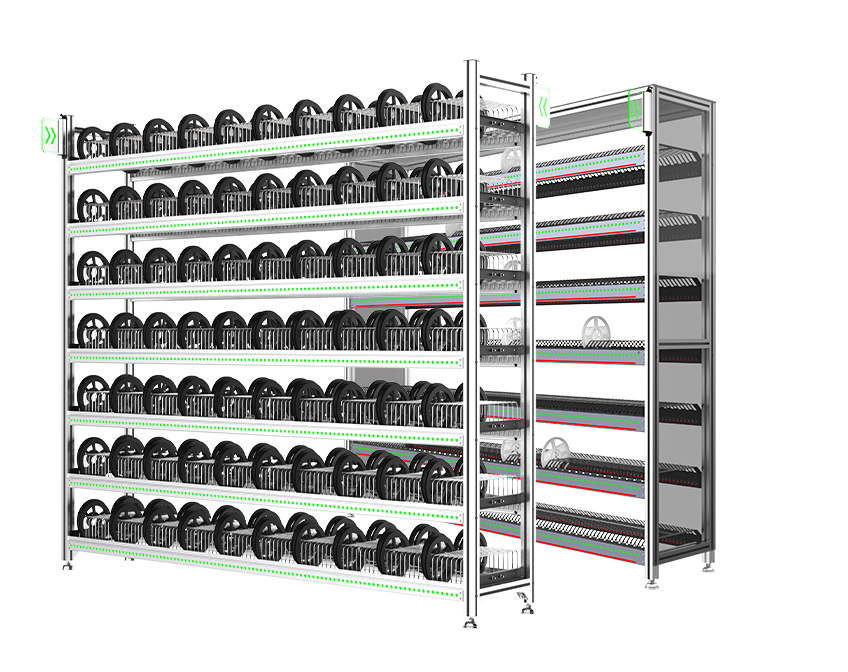

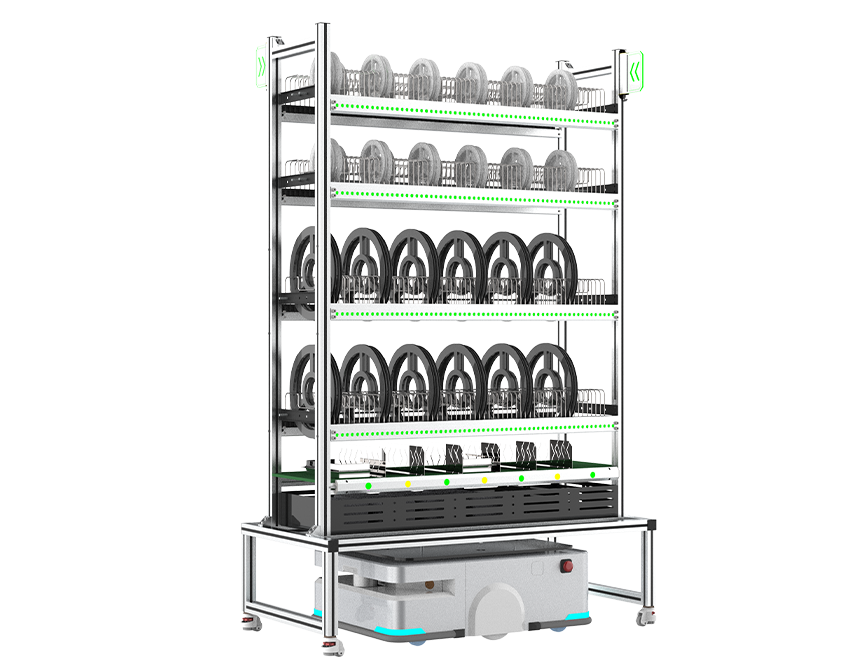

One of the key areas we specialize in at PassionIOT is the design and implementation of advanced material flow and conveyor systems. These systems are essential for maintaining smooth transitions of components and finished products across various stages of manufacturing. Our solutions cover a broad range of equipment, including Smart Vertical Carousel units and Smart Vertical Lift Modules, which support both vertical and horizontal material handling. By integrating these systems, we help manufacturers reduce manual handling errors, accelerate production cycles, and improve inventory accuracy. This integration is especially important in electronic manufacturing environments, where precision and timing are critical. We focus on providing flexible systems that can adapt to changing production demands, ensuring that materials flow efficiently and reliably.

Tailored Solutions That Support Complex Manufacturing Needs

Our approach to material flow is not one-size-fits-all. We recognize that different industries require customized conveyor and storage solutions that match their unique processes. PassionIOT’s portfolio includes smart storage for surface-mount devices (SMD), which is distinct from SMT lines, ensuring precise management of components critical to electronics manufacturing. Moreover, our vertical storage and carousel solutions are designed for scalability, enabling clients to expand capacity as their operations grow. By applying our deep technical knowledge and continuous innovation, we provide systems that streamline the entire flow of materials, reduce bottlenecks, and maximize space utilization. This adaptability allows us to serve a wide range of sectors beyond electronics, including automotive, pharmaceuticals, and logistics. Our focus on flexibility means we can tailor conveyor speeds, routing paths, and storage capacities to meet the evolving needs of our customers.

Conclusion

In conclusion, at PassionIOT, we believe that effective material flow and conveyor systems are foundational to achieving a more productive and agile manufacturing operation. Our expertise, spanning SMT line storage, vertical warehousing, and semiconductor-specific solutions, positions us well to meet the evolving demands of smart manufacturing. By collaborating closely with clients, we develop systems that not only improve efficiency but also support long-term operational resilience. We continue to invest in research and innovation to ensure our solutions align with industry trends and technological advancements. Ultimately, PassionIOT is dedicated to transforming how materials move within factories, helping businesses realize smarter, more connected manufacturing ecosystems that drive growth and operational excellence.