Solder paste, a critical material in electronics manufacturing, functions as both an adhesive and an electrical interconnect during Printed Circuit Board (PCB) assembly. Its consistency, wetting behavior, and reflow characteristics directly impact the placement accuracy of surface-mounted components and the overall reliability of the finished device.

Due to its chemical sensitivity, solder paste is prone to degradation when exposed to uncontrolled environments. Therefore, proper solder paste storage is essential for maintaining material stability and ensuring consistent production quality.

Proper Condition for Solder Paste Storage

Solder paste storage requires precise temperature management. Most formulations remain stable between 0°C-10°C. Exceeding this range can accelerate chemical breakdown, particularly within the flux, leading to poor wetting behavior and inconsistent printing. Conversely, exposure to excessively low temperatures or repeated freeze-thaw cycles can cause separation of components, making the paste difficult to remix and unreliable during application. Even short-term temperature deviations from the recommended range can shorten shelf life and alter key physical properties. .

In addition, solder paste should be stored in airtight containers to prevent exposure to air and moisture. High humidity can cause the solder paste to absorb moisture, which may affect its solderability and viscosity. Before use, solder paste should be brought to room temperature naturally (usually for 2–4 hours) without opening the container to avoid condensation, which can lead to moisture absorption.

It's also essential to observe FIFO (First In, First Out) inventory practices to ensure older paste is used before newer stock.

Common Solder Paste Storage Methods and Issues

1. Conveyor-based Loading System

Some cabinets utilize conveyor-based systems to transport solder paste into storage units, which has proven to have several limitations. Firstly, these systems are not compatible with bulk loading of syringe-type solder paste. Consequently, operators must load small quantities repeatedly, which augments their workload. Secondly, the slow feeding speed of this system results in low efficiency, prolonging production time and escalating costs.

2. Open-shelf Loading System

In open-shelf loading systems, operators manually place solder paste containers into exposed shelving inside storage units. Personnel may accidentally place containers in the wrong slot, retrieve the wrong item, or drop containers due to hand tremors or limited visibility, especially in fast-paced environments. Moreover, the open structure increases the risk of foreign objects or dropped containers falling into machine interiors, potentially causing malfunctions, downtime, and even injury to the staff.

3. Drawer-style Refrigeration

Although drawer-style refrigeration can be used for solder paste storage, it has a major drawback. During bulk loading and retrieval, the solder paste is exposed to the outside environment for an extended period. At that time, cold air escapes, and warm air enters the compartment. This results in noticeable temperature fluctuations inside the unit. The longer the paste is exposed outside the refrigerated zone, the greater the impact on its stability. Over time, repeated temperature cycling lowers the shelf life and alters the performance of the paste during application, compromising the soldering process and the overall quality of electronic products.

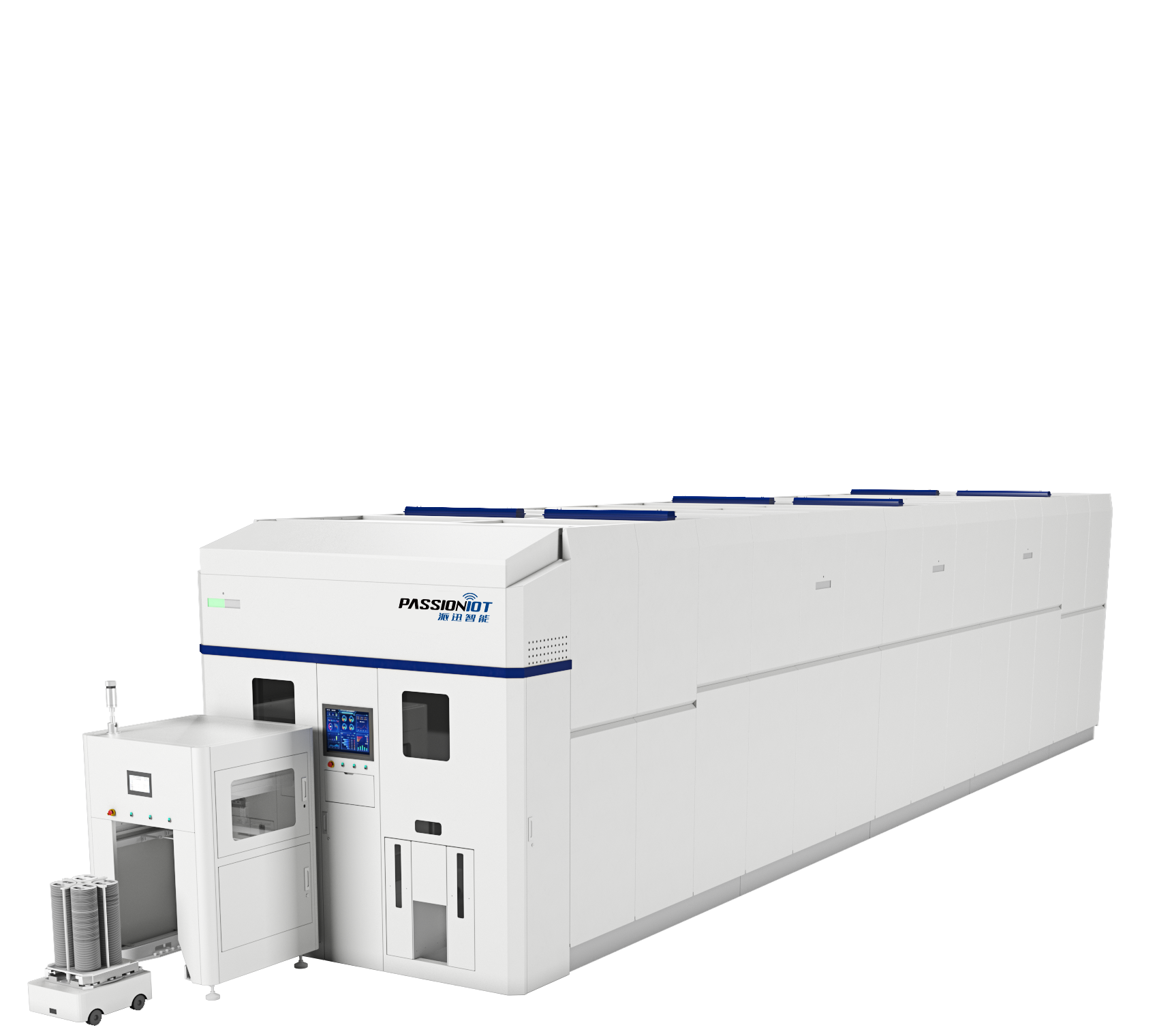

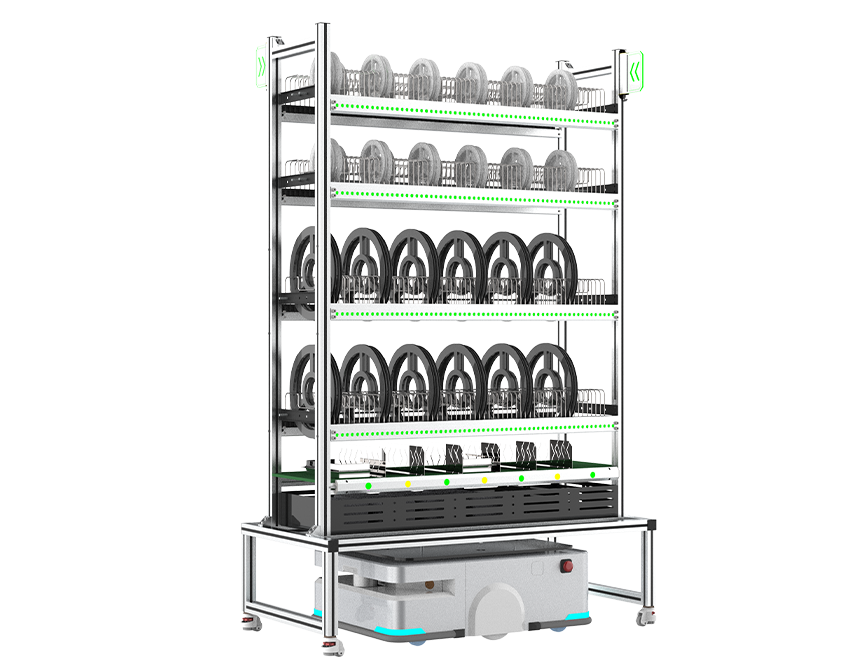

Solder Paste Storage from PassionIOT

So, how to store solder paste in an efficient manner? Our smart solder paste storage combines reliability, safety, and real-time oversight in one integrated system. It can help manufacturers guarantee a stable and reliable production process while minimizing defects and improving product yield.

1. Full-process Traceability

At PassionIOT, we understand that quality control is of utmost importance in electronics manufacturing. Our smart solder paste storage system provides complete process traceability by automatically tracking key parameters, including reflow timing, stirring activity, and storage duration. This data seamlessly integrates with factory systems like MES, ERP, or WMS, eliminating the need for error-prone manual recordkeeping. With full visibility into batch handling, manufacturers can closely monitor material usage, enabling early detection of potential issues

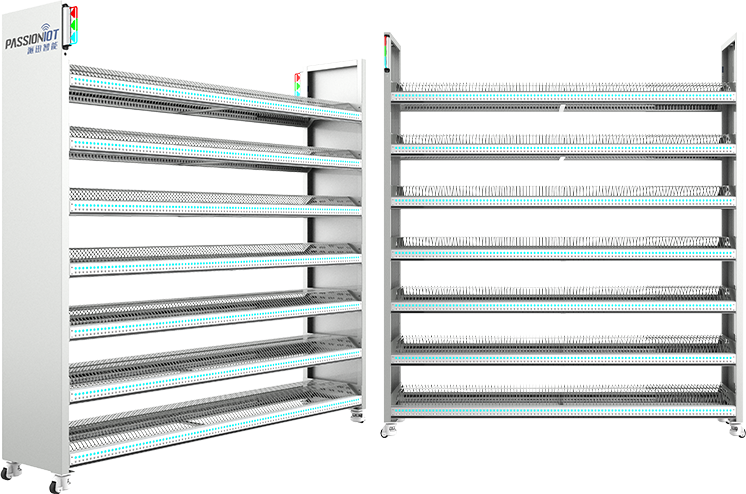

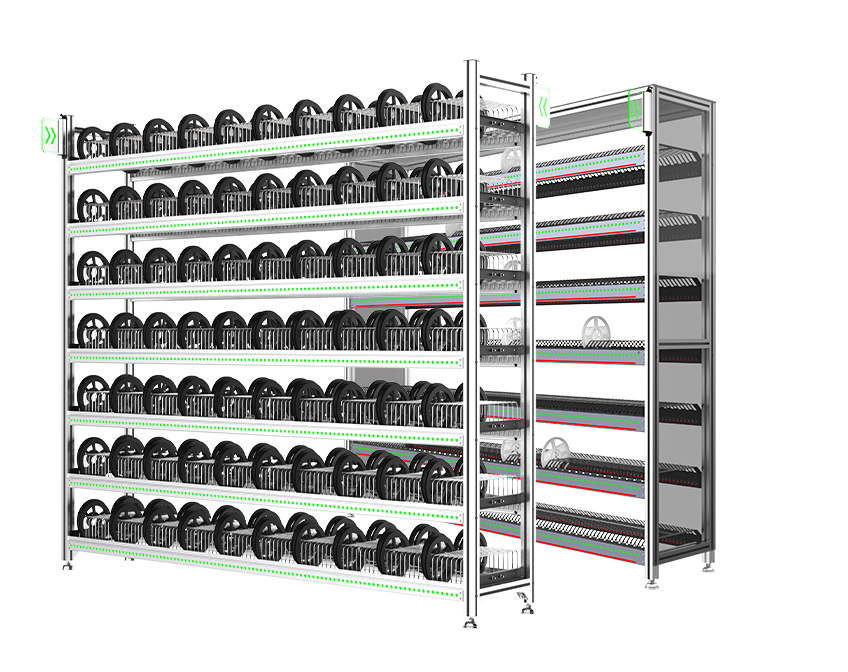

2. Innovative Structural Design

Our intelligent solder paste storage features an innovative structural design aimed at facilitating ease of use and securing safe operation:

(1) This intelligent storage solution supports bulk loading of both jar and syringe-type solder paste containers, capable of handling 16 units per batch. Its modular loading zone can be flexibly expanded to meet production demands; the more drawers added, the greater the loading capacity. A positioning limiter at the loading port ensures accurate placement of containers, preventing pick-up failures caused by misalignment.

(2) Its drawer-style configuration keeps operators from reaching into the machine’s interior, thereby promoting safe handling and maintaining system stability.

(3) The self-evaporative cooling module technology eliminates condensation, preventing container corrosion and solder paste contamination. A rotary-shelf mechanism allows for easy material access without fully pulling out the drawer, enhancing operational efficiency.

(4) Additionally, this advanced storage solution optimizes the access port to decrease cold air loss and stabilize internal temperature conditions, preserving the quality of stored solder paste over time.

Conclusion

As we have discussed, improper storage, whether due to temperature fluctuations, light exposure, or design flaws in the system, can significantly impact the quality of solder paste. Traditional methods, such as conveyor-based, open-shelf, or standard drawer systems, each have inherent limitations and fail to provide the necessary environmental control and operational efficiency.

At PassionIOT, our smart solder paste storage system integrates full-process traceability, innovative structural design, and advanced refrigeration technology, providing manufacturers with comprehensive visibility and control over their solder paste inventory.

Ready to revolutionize your solder paste management? Contact PassionIOT now!