In today’s fast-evolving manufacturing landscape, we at PassionIOT understand the critical role that advanced storage and automation solutions play in optimizing production lines. One of the key elements in electronics manufacturing is the handling of the surface mounted device components, which require precise and efficient storage management. By leveraging cutting-edge smart warehouse automation, we are able to support manufacturers in achieving greater efficiency, accuracy, and adaptability in their operations.

Streamlining Surface Mounted Device Handling

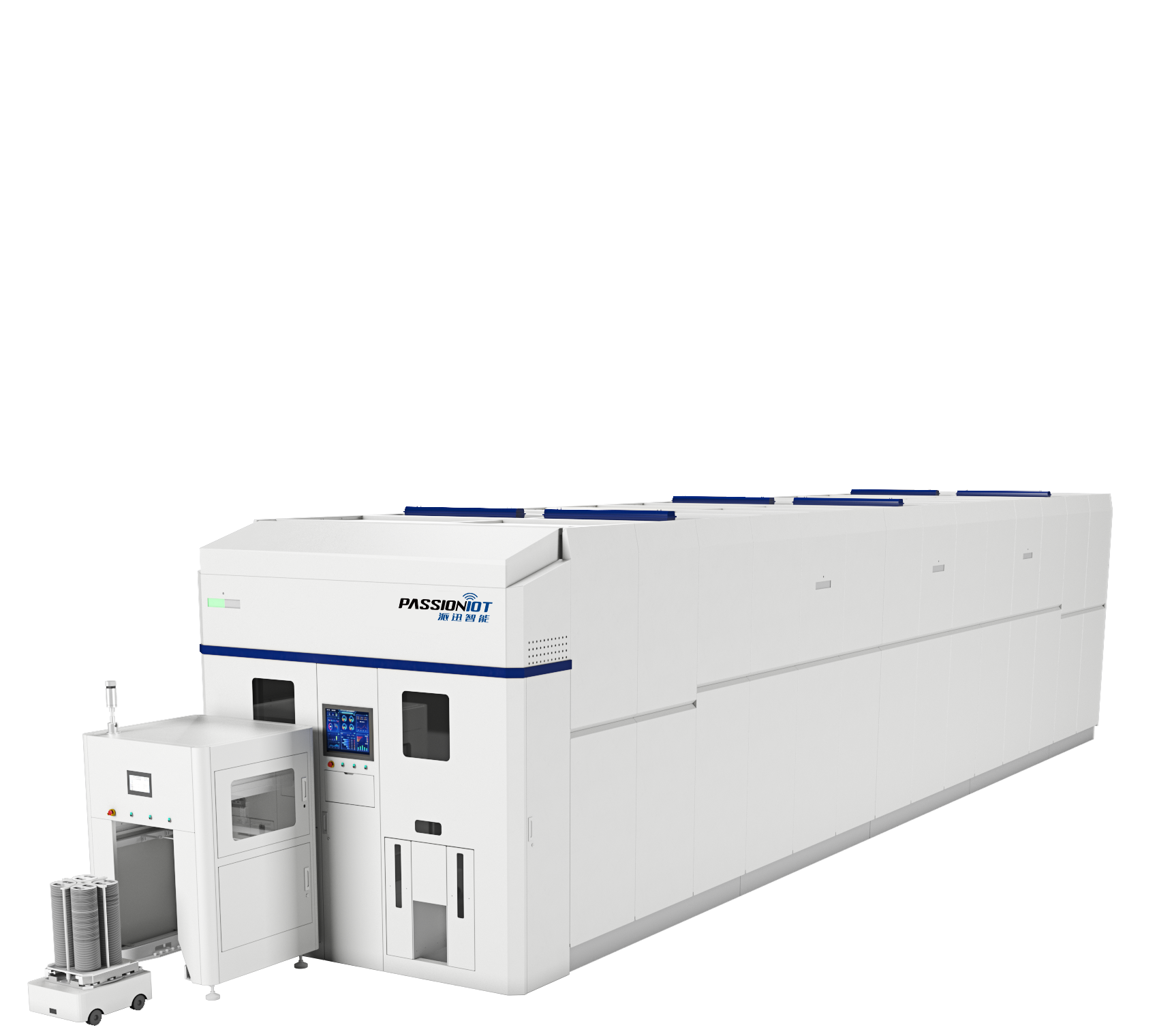

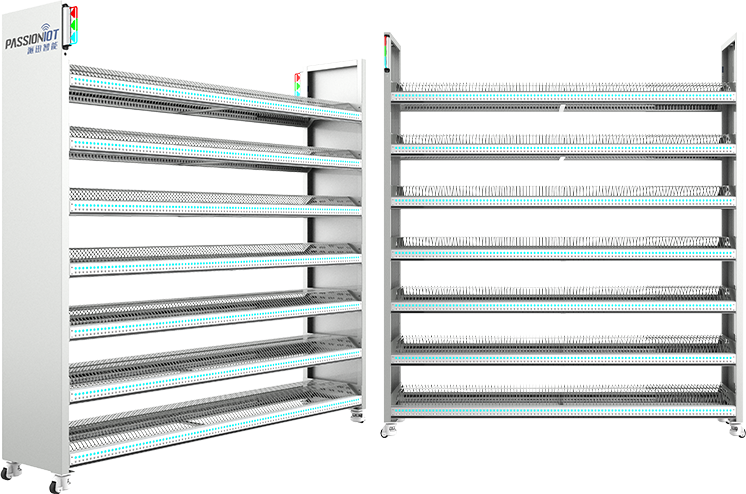

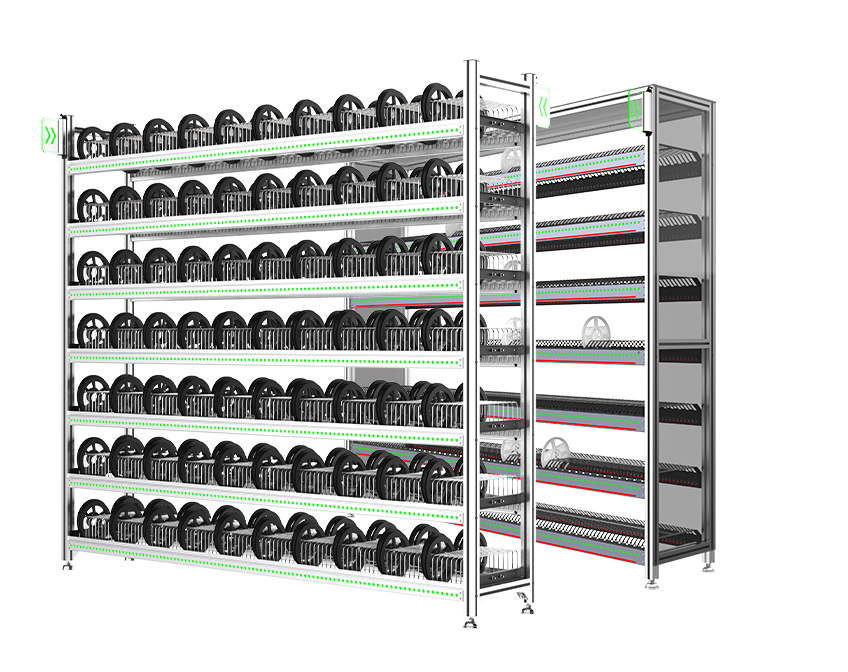

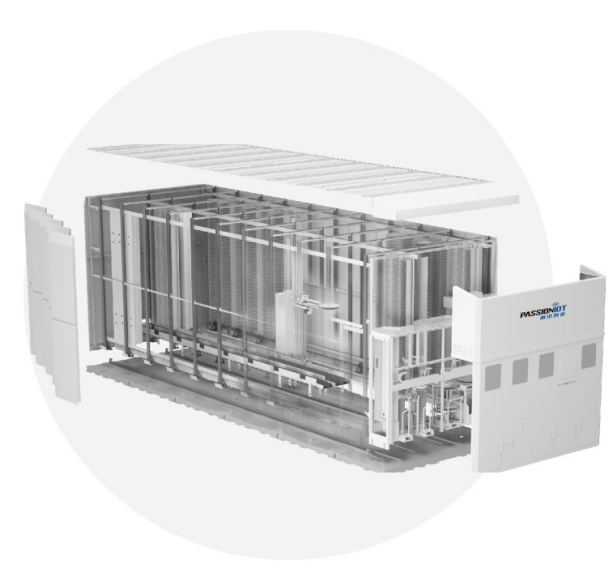

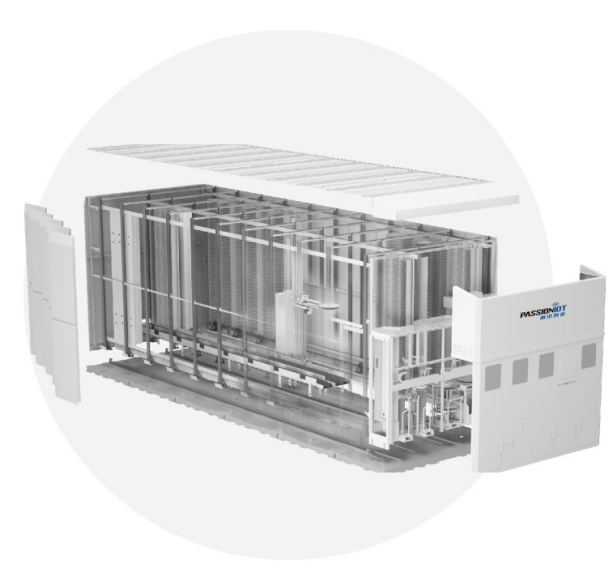

The proper management of surface mounted device components is vital to maintaining a smooth electronics assembly process. These small yet essential parts demand a storage system that minimizes errors and reduces downtime. At PassionIOT, we have developed a range of intelligent storage solutions such as the Smart Vertical Carousel and Smart Vertical Lift Module, which are specifically designed to handle these components efficiently. Our systems integrate seamlessly with production lines, allowing for quick retrieval and replenishment, which in turn improves overall productivity and reduces material waste.

The differences between SMT (surface mount technology) and SMD (surface mounted device) are often misunderstood. While SMT refers to the technology of mounting components, SMD specifically refers to the components themselves. We focus extensively on providing smart storage for these surface mounted device components to ensure the highest reliability and process stability in manufacturing environments.

The Power of Smart Warehouse Automation

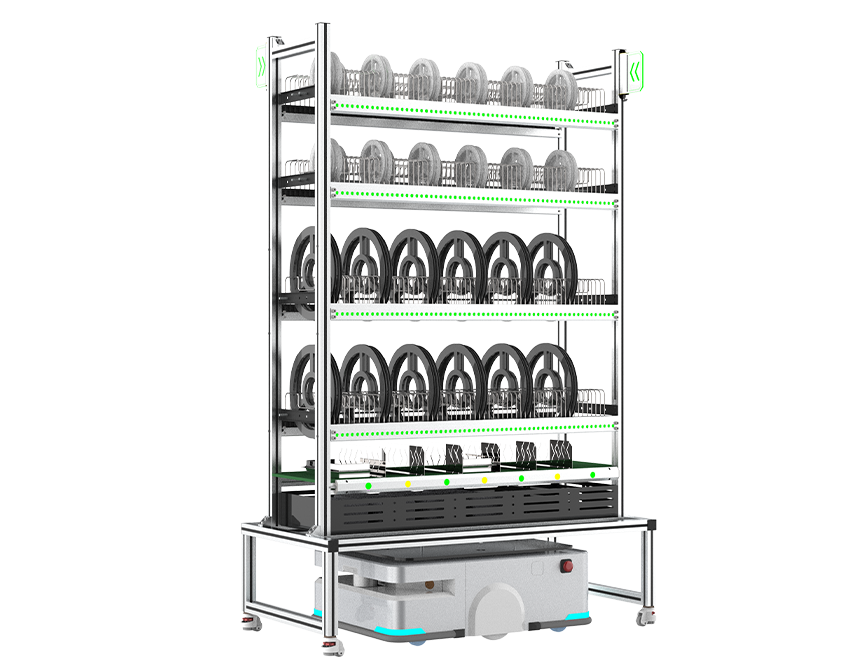

Implementing smart warehouse automation is no longer just an advantage but a necessity for modern manufacturers. Our solutions are built to provide real-time inventory tracking, automated stock management, and flexible storage configurations that adapt to changing production needs. By incorporating robotics and AI-driven systems, PassionIOT ensures that warehouse operations not only save time but also maintain high standards of accuracy and safety. These technologies enable manufacturers across various industries to optimize space utilization and reduce labor costs without compromising on speed or quality.

One of the standout features of our smart warehouse automation solutions is the ability to integrate various equipment, such as automated guided vehicles (AGVs), vertical lift modules, and rotary storage units. This integration forms a cohesive system that enhances workflow continuity and reduces human error, especially important when dealing with high-volume surface mounted device components in electronics manufacturing.

Conclusion

As we continue to evolve, PassionIOT remains committed to delivering innovative solutions tailored to the specific requirements of smart manufacturing. Our focus on efficient management of surface mounted device parts and advanced smart warehouse automation technologies helps our clients stay competitive and responsive to market demands. We believe that smart storage systems are a cornerstone of future manufacturing success, and through ongoing innovation, we aim to empower industries to operate more intelligently and sustainably.

Through our efforts, manufacturers gain greater visibility over their inventory, improve operational throughput, and reduce costs associated with material handling. At PassionIOT, we are proud to contribute to a future where smart warehouses transform traditional manufacturing environments into intelligent, automated hubs that meet the challenges of modern production with confidence.