Manufacturing operations today face increasing pressure to improve space utilization, reduce operational costs, and streamline workflows. One effective way to address these challenges is by implementing an automated storage and retrieval system, which significantly enhances inventory management, reduces manual labor, and improves overall productivity. We have observed how integrating the right AS RS system can transform warehouse efficiency, supporting not only production goals but also long-term business growth across diverse industries, including electronics and semiconductor manufacturing.

How Automated Storage and Retrieval System Transforms Manufacturing

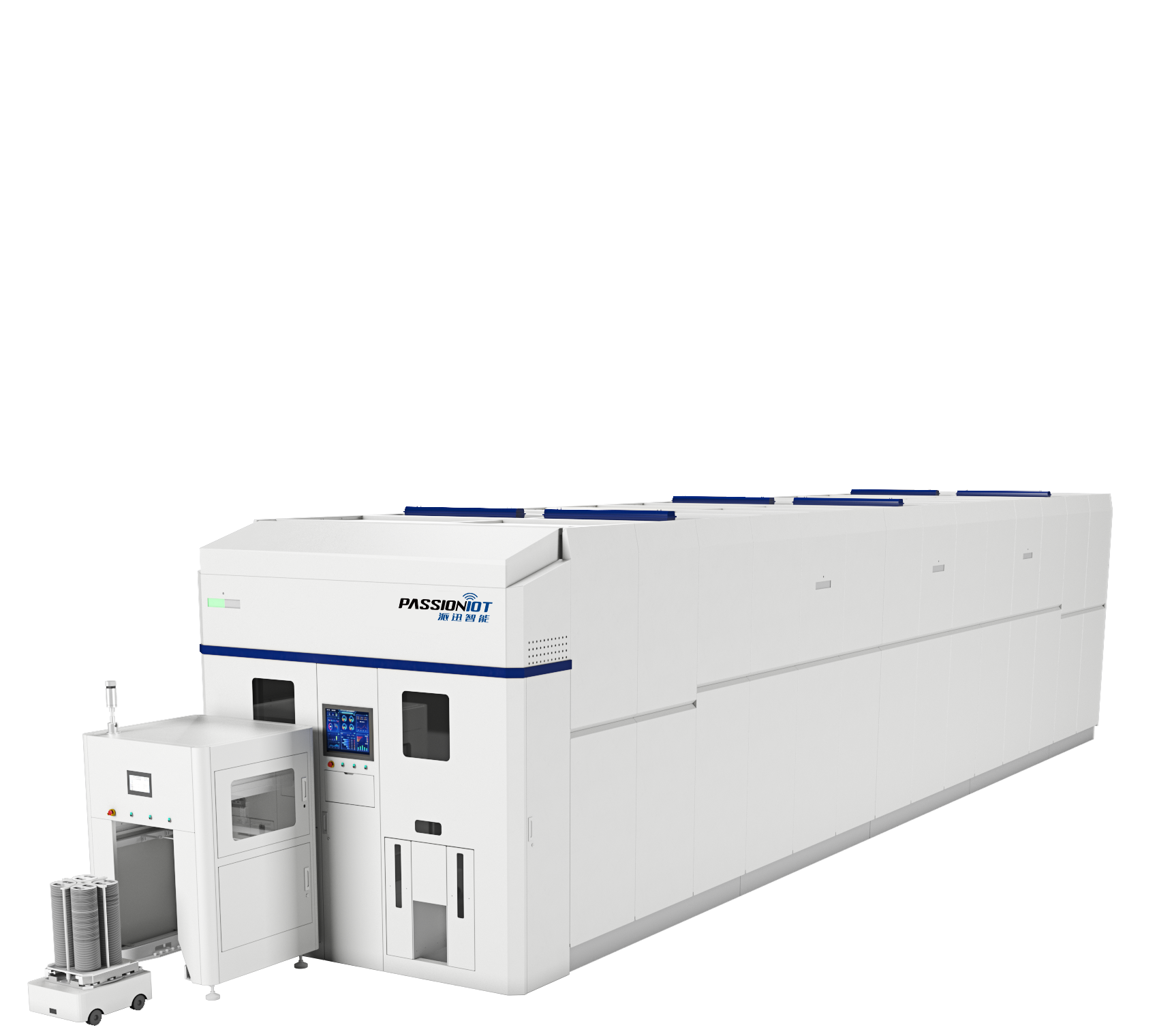

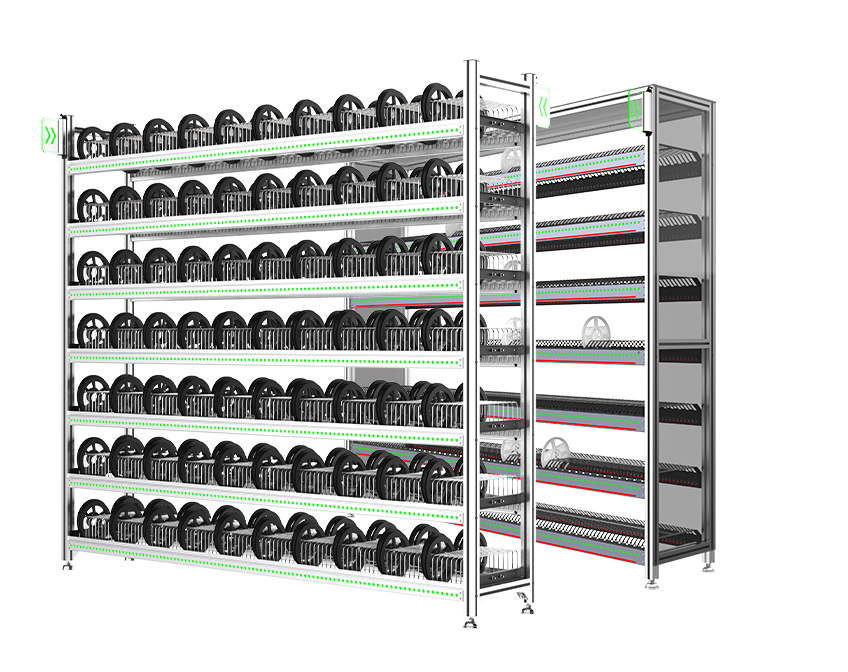

Incorporating an automated storage and retrieval system into production lines provides a range of operational advantages. These systems automatically manage the placement and retrieval of goods within storage facilities, minimizing manual intervention and significantly reducing the risk of human error. Our solutions at PassionIOT include advanced AS RS system designs tailored to meet the specific needs of various manufacturing sectors. Whether it involves handling SMT components, wafer storage, or general inventory, our systems are built to improve storage density, accelerate access times, and enhance inventory accuracy.

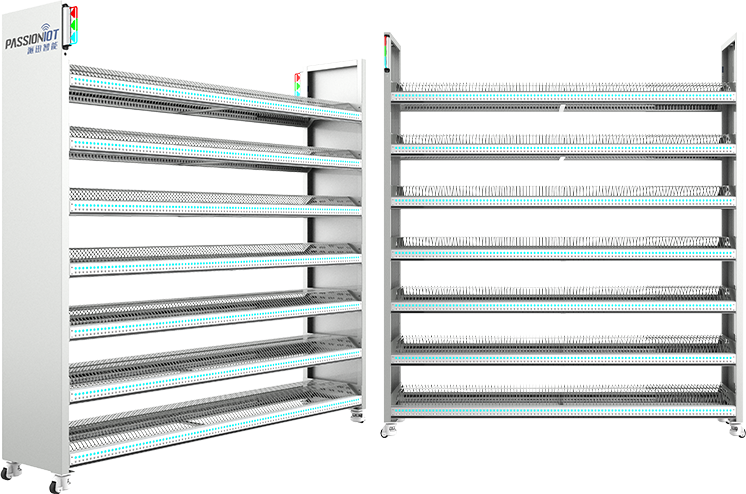

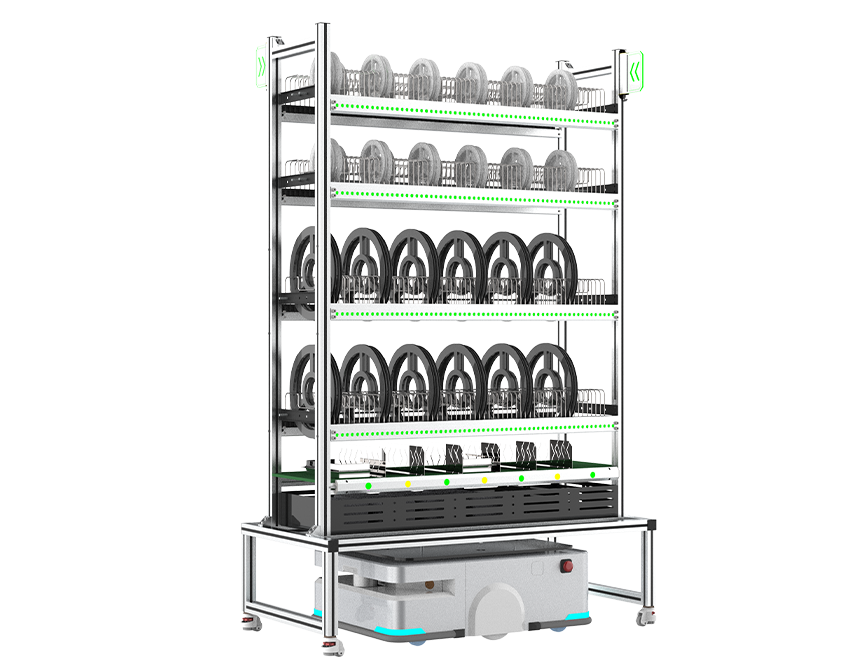

Our key products, such as the Smart Vertical Carousel and Smart Vertical Lift Module, exemplify how automated storage and retrieval system technology can optimize space and increase throughput. These systems are designed to reduce time spent locating and picking parts, helping production teams maintain a smooth workflow. The flexibility of our AS RS system solutions allows companies to adapt quickly to changing production demands, which is vital in fast-paced manufacturing environments.

Seamless Integration and Smart Control with PassionIOT’s AS/RS System

Integration of our automated storage and retrieval system requires thorough understanding of a client’s existing workflows and future plans. We prioritize creating an adaptable AS RS system that not only fits seamlessly into current operations but also offers scalability as storage needs evolve. Collaborating closely with customers, we ensure our solutions address unique storage challenges while maintaining ease of operation.

A standout feature of our systems is the intelligent control software that enables real-time inventory monitoring and management. This allows companies to gain full visibility over stock levels, improving decision-making for replenishment and order fulfillment. By creating a connected ecosystem, PassionIOT’s solutions link warehouse storage, production schedules, and logistics into a coherent and efficient process, supporting broader digital transformation initiatives.

Conclusion

Looking forward, manufacturing efficiency will continue to depend heavily on intelligent automation and integrated solutions. The automated storage and retrieval system and AS RS system provided by PassionIOT play an essential role in helping companies maximize warehouse space, improve operational workflows, and reduce costs. Adopting these technologies not only enhances accuracy and productivity but also supports companies in responding swiftly to market changes and customer needs. Our ongoing commitment is to deliver reliable, scalable, and forward-thinking storage solutions that grow with our clients and industry trends.