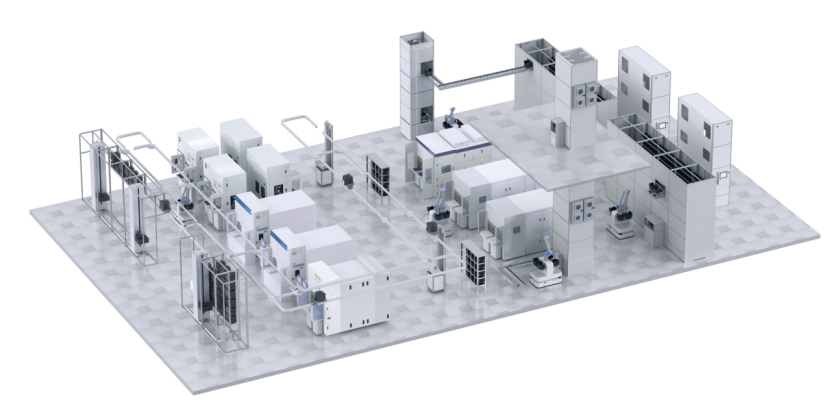

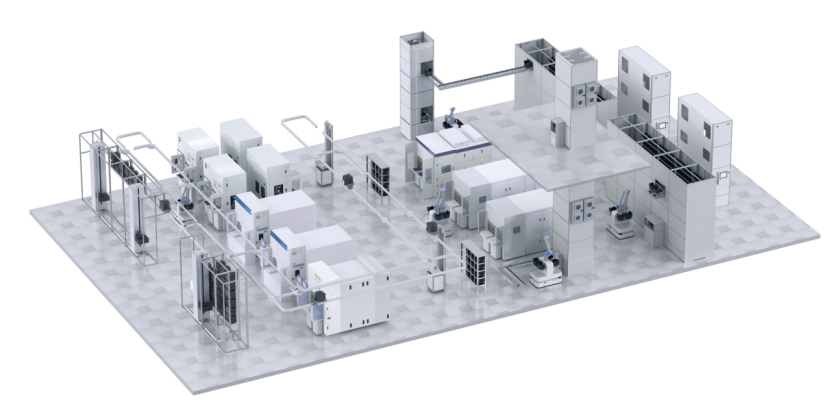

Our expertise lies in creating efficient, reliable, and scalable manufacturing environments that adhere to the strictest standards of cleanliness, precision, and data integration. As we navigate the complexities of semiconductor technology, we are committed to delivering innovative solutions that enhance productivity and reduce waste.

Meeting Harsh Environmental Standards

In the world of semiconductor manufacturing, the workshop environment is critical. To ensure optimal performance, it must meet stringent dust, anti-static, and vibration standards. At PassionIOT, we understand that even the smallest contaminants can jeopardize production quality. Our semiconductor manufacturing solutions are designed to create a controlled environment that minimizes these risks, allowing for the reliable operation of sensitive equipment. We invest in advanced filtration systems and anti-static technology to maintain the cleanliness required for high-precision manufacturing.

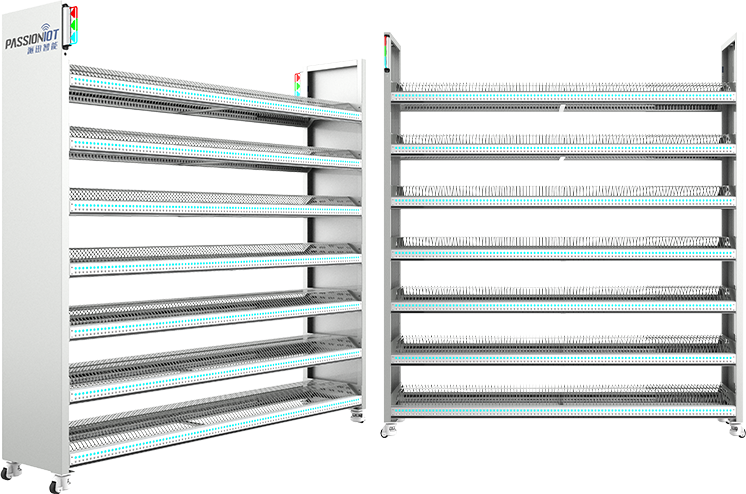

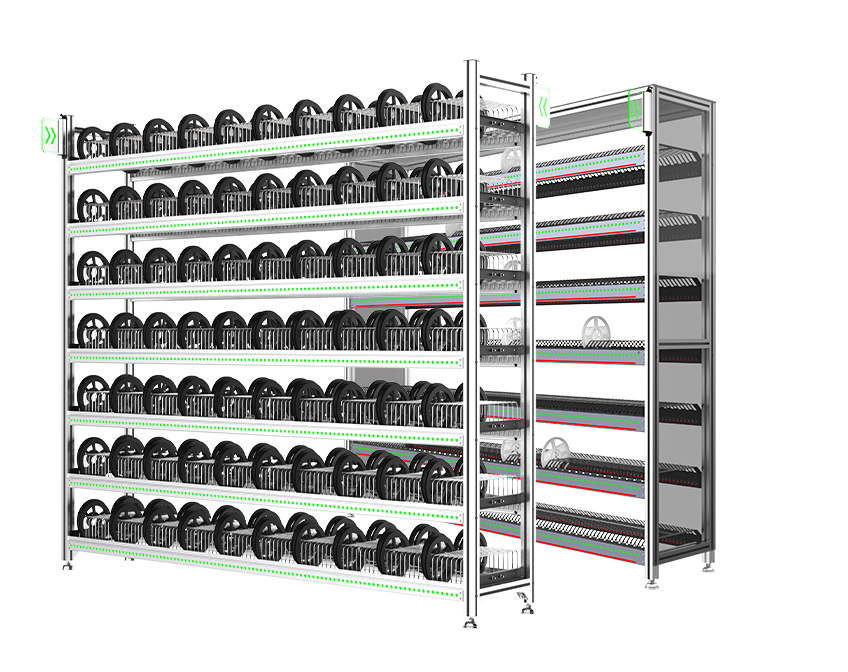

Optimizing Production Space

Inventory management in semiconductor manufacturing can quickly become a challenge. To sustain continuous and stable production, manufacturers often find themselves with excessive inventory piled up on production lines, which can lead to inefficient use of space. PassionIOT's automotive semiconductor solutions focus on optimizing production layouts and inventory systems. By implementing smart inventory management techniques, we help companies maximize their production space, ensuring that every square foot is utilized effectively. This not only improves operational efficiency but also enhances the overall productivity of the manufacturing process.

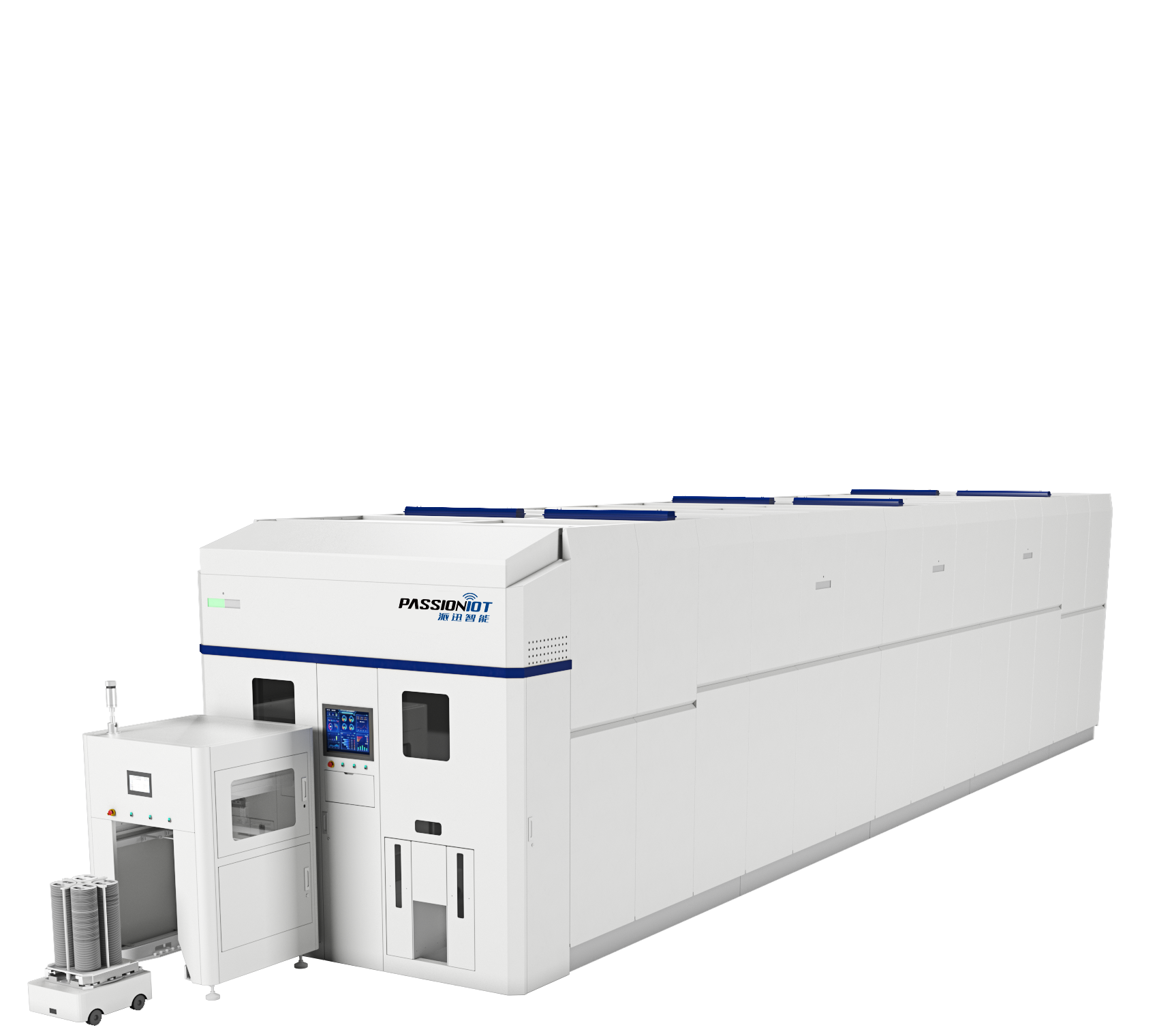

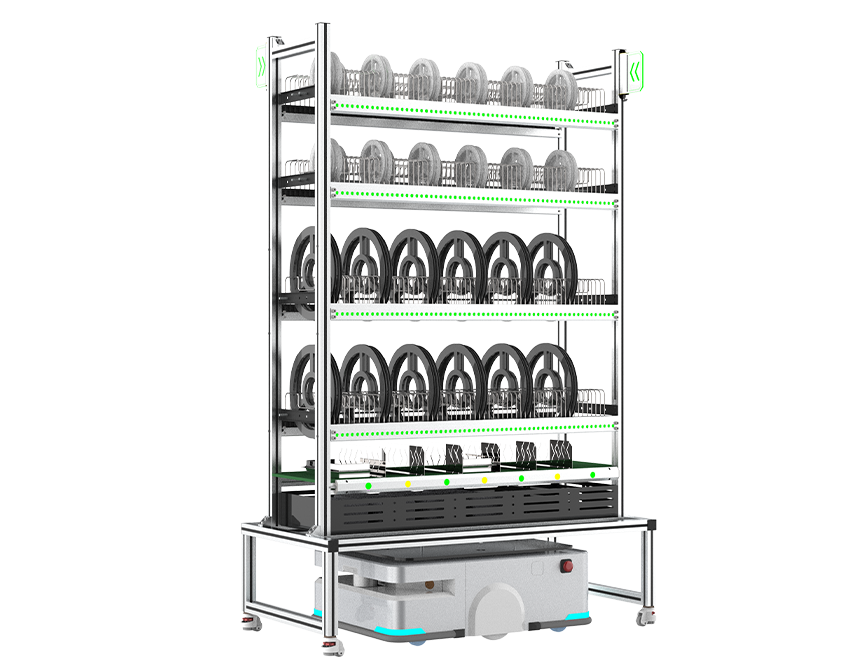

Enhancing Precision through Automation

Manual operations in semiconductor manufacturing can introduce several issues, including large vibrations, discontinuous operation, and low precision. These factors can easily lead to material loss and wasted production capacity. PassionIOT offers automotive semiconductor solutions that prioritize automation. By integrating advanced robotics and automated systems, we minimize the risks associated with manual handling. Our solutions ensure that operations are executed with high precision and consistency, significantly reducing the potential for errors and maximizing output.

Bridging Information Islands

One of the significant challenges in semiconductor manufacturing is the issue of information islands. The data generated across various stages of wafer production is often scattered, impacting the overall production rhythm. PassionIOT addresses this challenge by implementing comprehensive data integration systems within our semiconductor manufacturing solutions. By connecting equipment and centralizing data, we facilitate seamless communication across the production line. This enhances decision-making and allows for real-time adjustments, ultimately leading to improved efficiency and reduced downtime.

Conclusion

In conclusion, PassionIOT is dedicated to revolutionizing the semiconductor manufacturing landscape through our specialized solutions. By focusing on harsh environmental standards, optimizing production space, enhancing precision through automation, and bridging information gaps, we strive to deliver unparalleled value to our clients. Our semiconductor manufacturing solutions are designed to empower businesses to thrive in a highly competitive industry. Let us partner with you to unlock the full potential of your semiconductor manufacturing processes and drive your success forward.