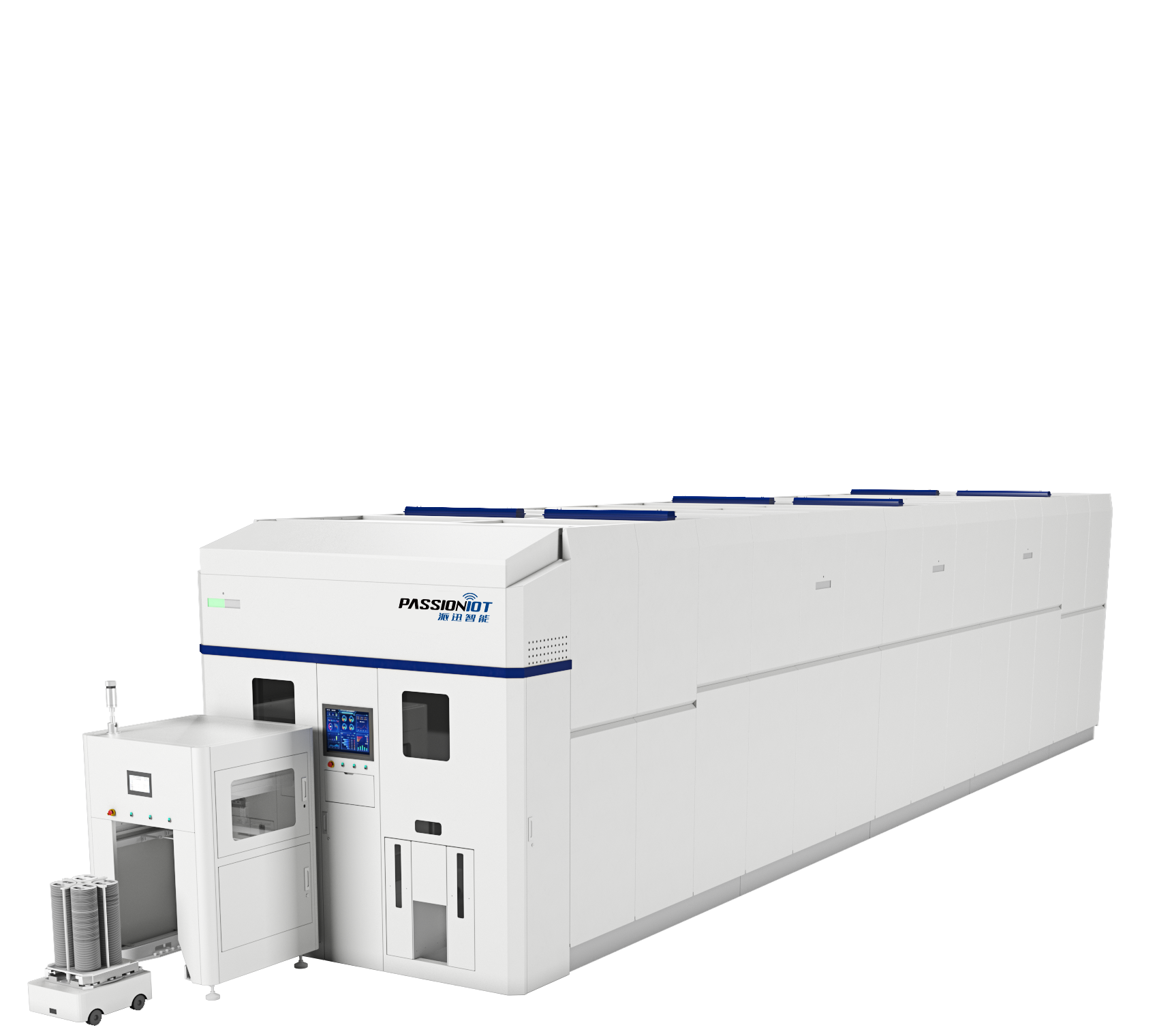

In the fast-paced environment of electronics manufacturing, accuracy and efficiency in component counting are essential for maintaining productivity and quality standards. The PassionIOT Inline X-Ray reel counter is specifically designed to meet these demands by providing a high-volume, reliable solution for counting surface mount device (SMD) reels. With features such as AI-powered label positioning and compatibility with all reel types, our X-Ray reel counter is positioned as an industry leader in SMD component management.

Enhanced Accuracy with Advanced Technology

One of the defining characteristics of our X-Ray reel counter is its advanced recognition algorithms that facilitate precise counting with an accuracy rate of 99.99%. This exceptional level of accuracy is crucial for large-scale enterprises that rely on consistent inventory tracking for their SMD components. By minimizing counting errors, we enable manufacturers to maintain accurate records and ensure that they have the necessary components available for production schedules.

The technology behind the X-Ray SMD component counter allows it to handle a wide variety of reel sizes, ranging from 7 to 15 inches. This flexibility ensures that businesses can integrate our counter into their existing workflows, regardless of the types of reels they use, thereby enhancing overall efficiency in the counting process.

AI-Powered Label Positioning for Efficiency

Another innovative feature of the PassionIOT X-Ray reel counter is the industry-exclusive AI-powered label positioning technology. This advanced system automatically identifies available blank areas on the reels for optimal label placement. As a result, labels can be applied accurately and consistently, eliminating the potential for mislabeling and improving overall organization.

By automating the labeling process, we reduce the time and effort needed for manual label placement, allowing operators to focus on other critical tasks within the production environment. This aspect of our X-Ray reel counter significantly enhances operational efficiency and contributes to a streamlined material management process.

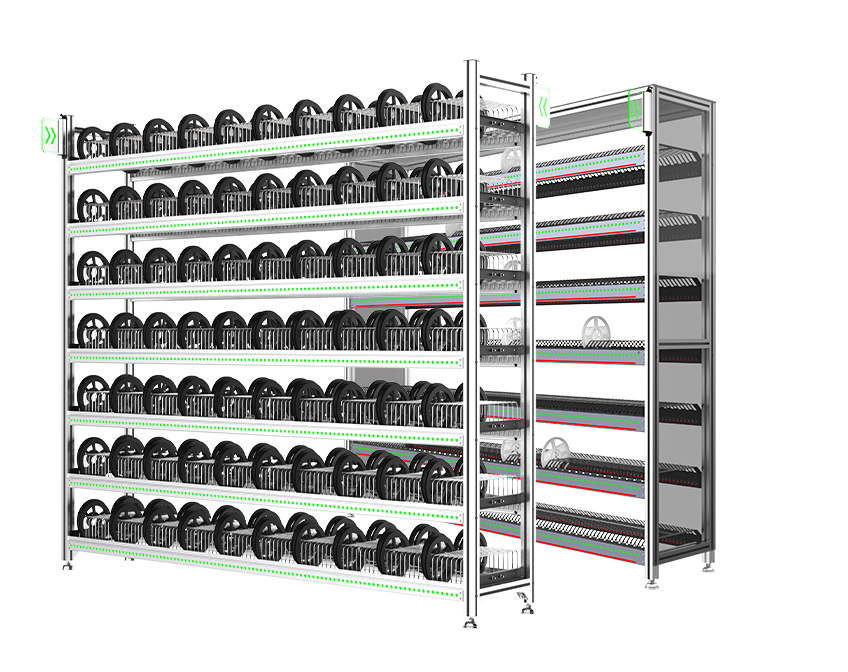

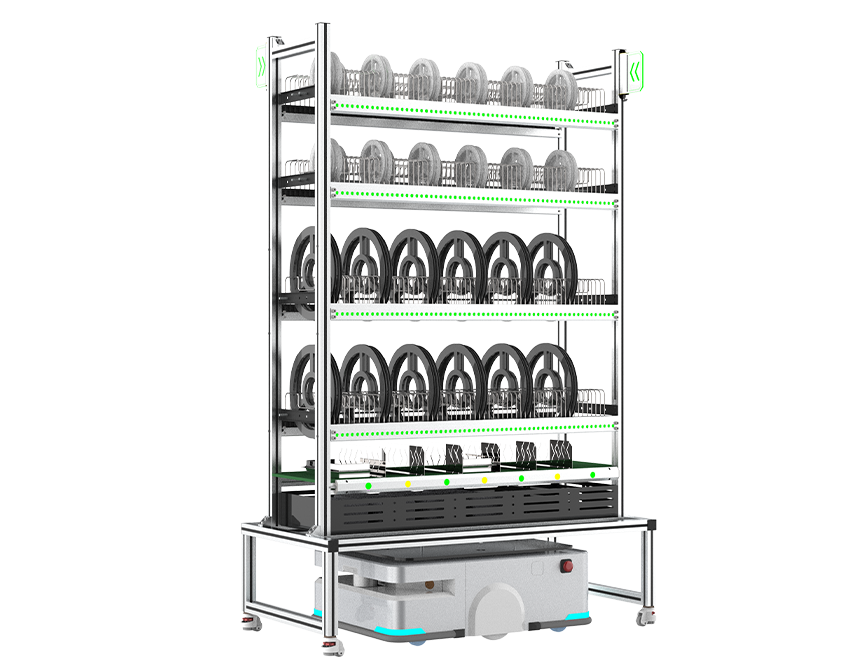

Compatibility with All Reel Types

The versatility of our Inline X-Ray Reel Counter also extends to its compatibility with various reel types. It supports reel heights up to 90 mm and accommodates all material specifications commonly found in the market. This adaptability makes our counter an invaluable asset for diverse manufacturing settings, ensuring that businesses can count and manage SMD components effectively, regardless of their specific requirements.

By being fully compatible with a range of reel types, our X-Ray SMD component counter provides organizations with the flexibility needed to adapt to changing production needs while maintaining high standards of accuracy and reliability.

In conclusion, the PassionIOT Inline X-Ray Reel Counter represents a significant advancement in the field of SMD component management. With its AI-powered label positioning and full compatibility with all reel types, we offer businesses a robust solution for achieving precise and efficient counting processes. As we continue to innovate in this space, we encourage organizations to explore how our X-Ray reel counter can optimize their operations and enhance overall productivity.