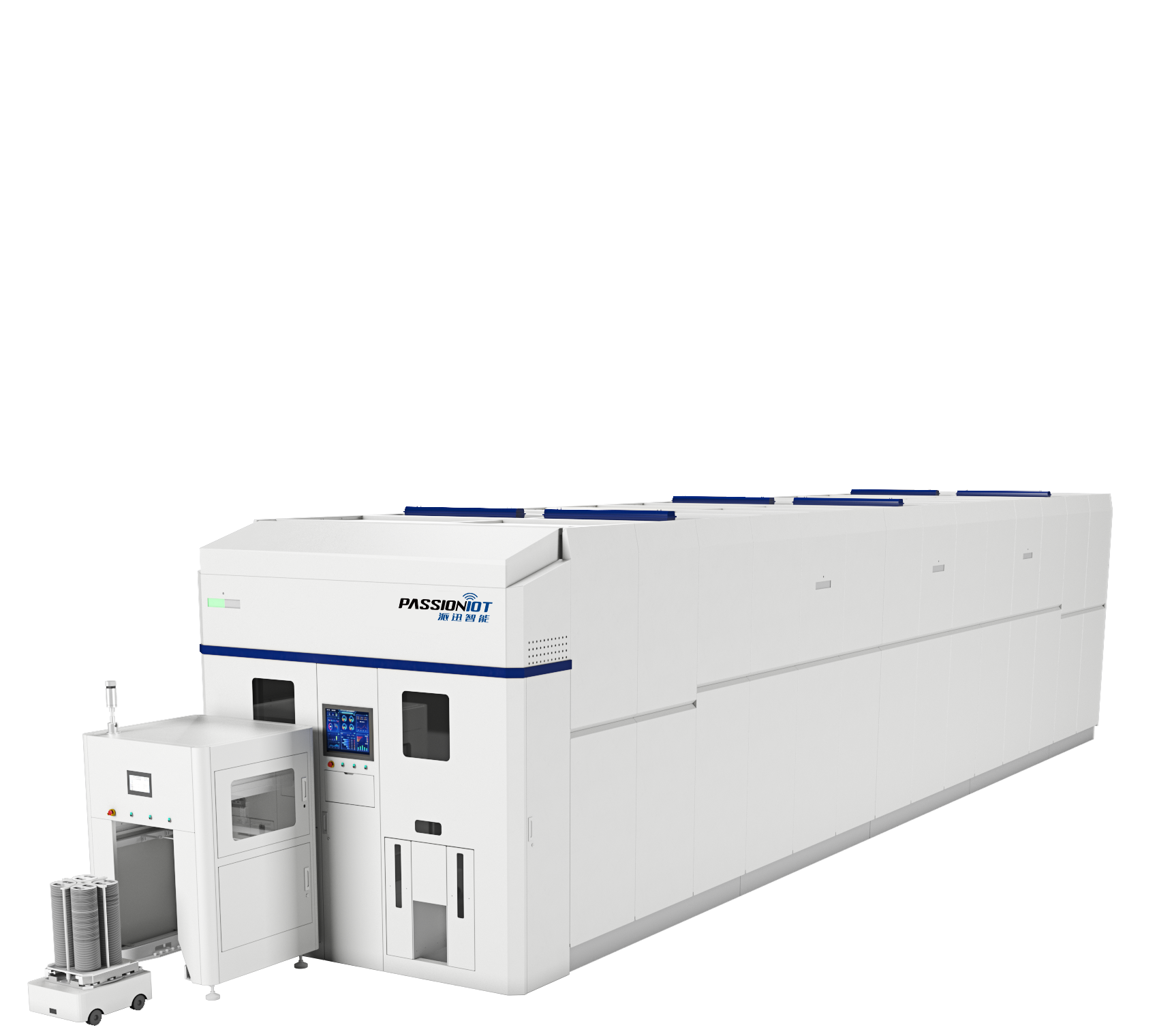

In the fast-paced world of manufacturing, precision and efficiency are crucial, especially when it comes to managing SMD components. PassionIOT is proud to introduce the Inline X-Ray Reel Counter, a cutting-edge solution designed specifically for high-volume, continuous SMD reel counting. With a focus on accuracy and integration, this system is tailored for large-scale enterprises looking to optimize their material management processes.

Unmatched Accuracy and Speed

The Inline X-Ray Reel Counter stands out for its remarkable accuracy and speed, achieving an impressive 99.99% accuracy across various reel sizes ranging from 7 to 15 inches. This level of precision is essential for businesses that rely on an X-Ray component counter to ensure quality and reliability in their operations. With a rapid detection speed of approximately 10 seconds per reel, this system minimizes bottlenecks and enhances productivity, allowing for uninterrupted workflows in high-demand environments.

By utilizing advanced recognition algorithms, the x-ray SMD component counter effectively reduces manual errors that often plague traditional counting methods. This improvement not only saves time but also ensures that inventory levels are accurately maintained, supporting better decision-making across the supply chain.

Seamless Integration with Existing Systems

One of the key features of the Inline X-Ray Reel Counter is its ability to seamlessly integrate with existing ERP, MES, and WMS systems. This compatibility allows for real-time data output, enabling businesses to maintain up-to-date inventory records and streamline their operations. By incorporating the x-ray component counter into their material management processes, companies can achieve a higher level of operational efficiency and transparency.

The integration capabilities of the x-ray SMD component counter also facilitate better communication between departments, ensuring that all stakeholders have access to accurate data. This connectivity is vital for effective planning and resource allocation, ultimately leading to improved productivity and reduced costs.

Optimized for Industrial Environments

Designed specifically for industrial settings, the Inline X-Ray Reel Counter is built to withstand the rigors of high-volume operations. Its inline design allows for large-batch reel counting without interruption, making it ideal for environments where time and efficiency are critical. This focus on operational continuity helps businesses to maintain smooth workflows, even during peak demand periods.

By implementing the Inline X-Ray Reel Counter, companies can enhance their material management processes, reduce errors, and optimize their overall efficiency. This commitment to quality and performance positions PassionIOT as a leader in the field of advanced counting solutions.

In conclusion, the Inline X-Ray Reel Counter from PassionIOT represents a significant advancement in x-ray component counting technology. With its unmatched accuracy, seamless integration, and robust design, this X-Ray SMD component counter is an essential tool for any large-scale enterprise looking to improve operational efficiency. We invite you to explore how PassionIOT can help your business achieve its goals in today’s competitive landscape.