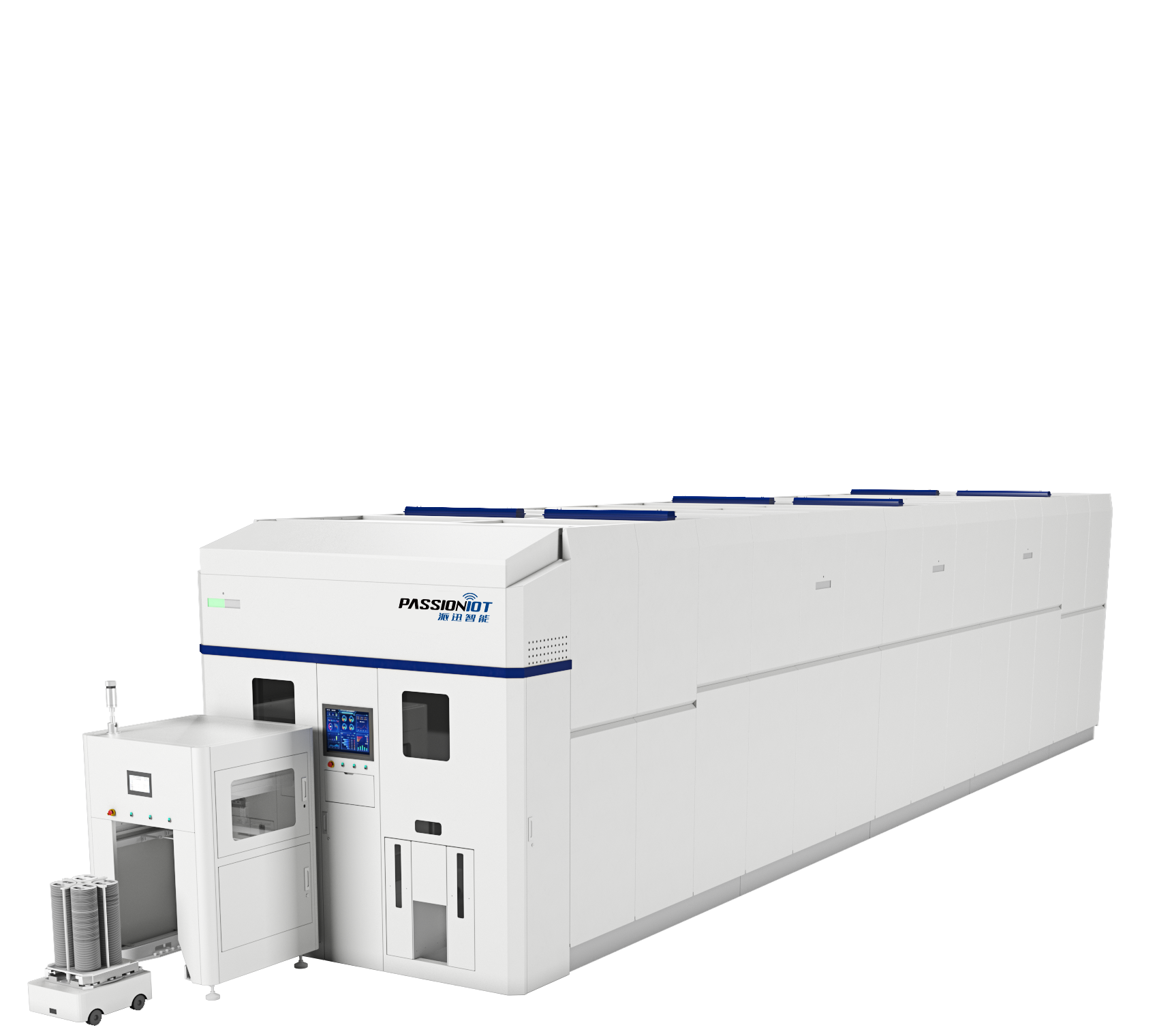

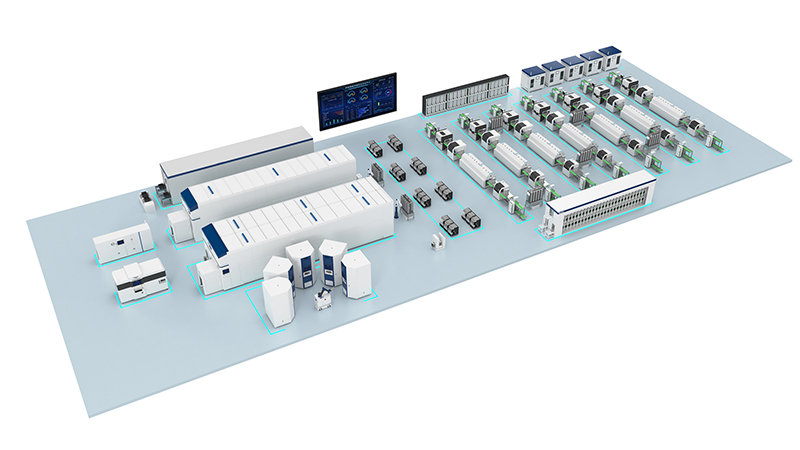

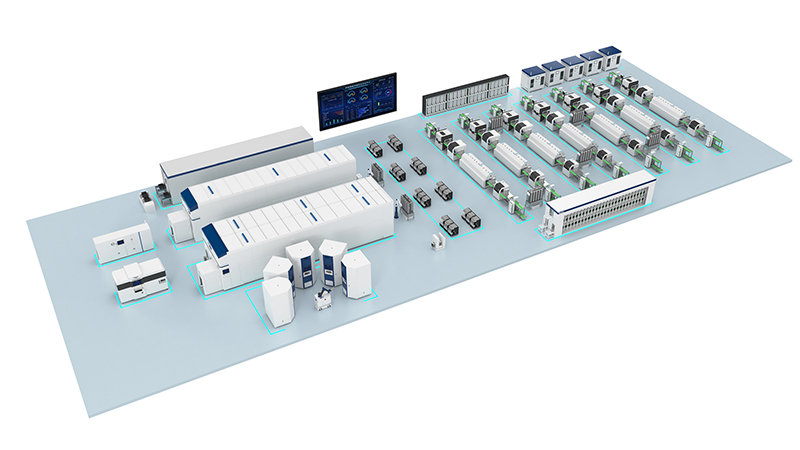

In the competitive landscape of electronics manufacturing, efficient production processes are crucial for meeting market demands. We recognize the necessity of implementing high-quality SMT line solutions that enhance productivity and reduce operational costs. Our SMT Production Line Solutions are designed to address these needs, offering a comprehensive approach to modern manufacturing.

Automation and Precision in SMT Line Solutions

Our SMT Production Line Solutions are characterized by automation, high precision, and high speed. These features allow us to achieve greater efficiency in our operations while maintaining the quality standards required in today's market. By integrating advanced technologies, we can significantly increase production capacity and reduce the likelihood of errors.

As SMT machine manufacturers, we focus on creating systems that not only automate tasks but also deliver precise results. This precision is essential for the complex assembly processes involved in electronics manufacturing, where even minor inaccuracies can lead to significant setbacks. Our SMT line solutions are engineered to minimize these risks and ensure consistent output.

Real-Time Information Exchange

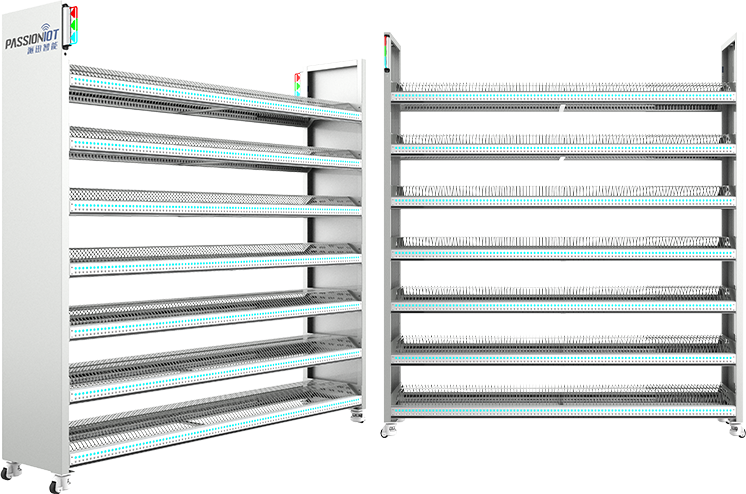

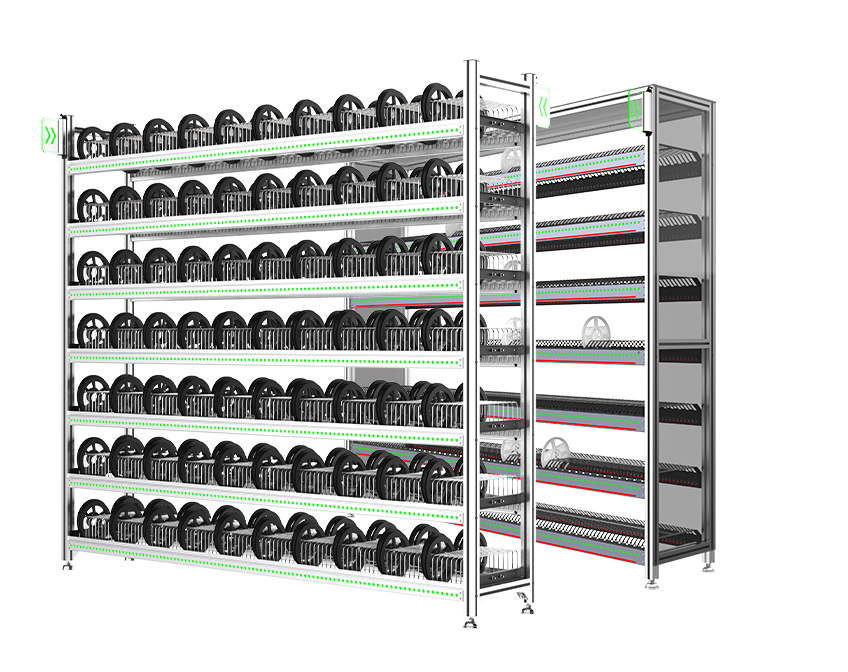

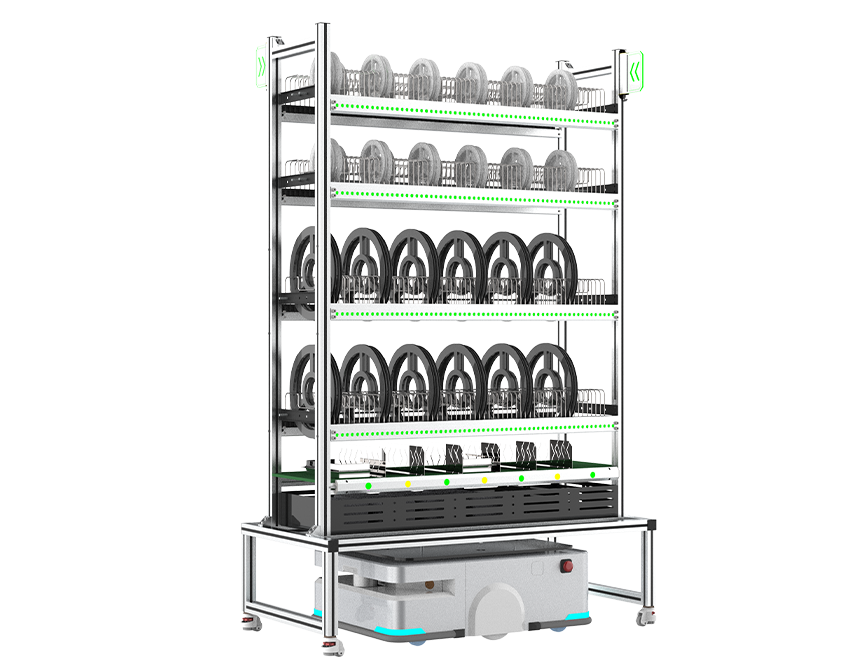

Another key advantage of our SMT Production Line Solutions is the ability to realize seamless information exchange. We understand that real-time data is critical for effective inventory management and production planning. Our solutions allow for direct integration with existing factory systems, enabling us to update in/out and inventory information in real time.

This connectivity ensures that we have access to accurate data, which is vital for making informed decisions and optimizing production schedules. By leveraging real-time information, we can respond quickly to changes in demand and streamline our operations, further enhancing the effectiveness of our SMT line solutions.

Unified Scheduling for Enhanced Coordination

Our SMT Production Line Solutions also feature a unified scheduling system that coordinates different equipment and processes. This integration allows us to share information across various machines, improving overall workflow and reducing downtime. By synchronizing operations, we can maximize the efficiency of our production line, ensuring that each component operates at its optimal capacity.

The ability to manage scheduling through a centralized system is essential for maintaining high levels of productivity. It allows us to minimize idle time and ensure that resources are utilized effectively, contributing to the overall success of our manufacturing processes.

Conclusion: The Future of Electronics Manufacturing

In conclusion, our SMT Production Line Solutions represent a significant advancement in the field of electronics manufacturing. By focusing on automation, real-time information exchange, and unified scheduling, we provide a comprehensive framework that addresses the complexities of modern production.

For businesses looking to enhance their manufacturing capabilities, we recommend PassionIOT. Our commitment to quality and innovation positions us as a trusted partner among SMT machine manufacturers, enabling us to drive efficiency and productivity in your operations. By adopting our SMT line solutions, we can help you navigate the challenges of the electronics market and achieve sustainable success.